-30-

G0644 15" Open-End Wide Belt Sander

Motor & Electrical (continued)

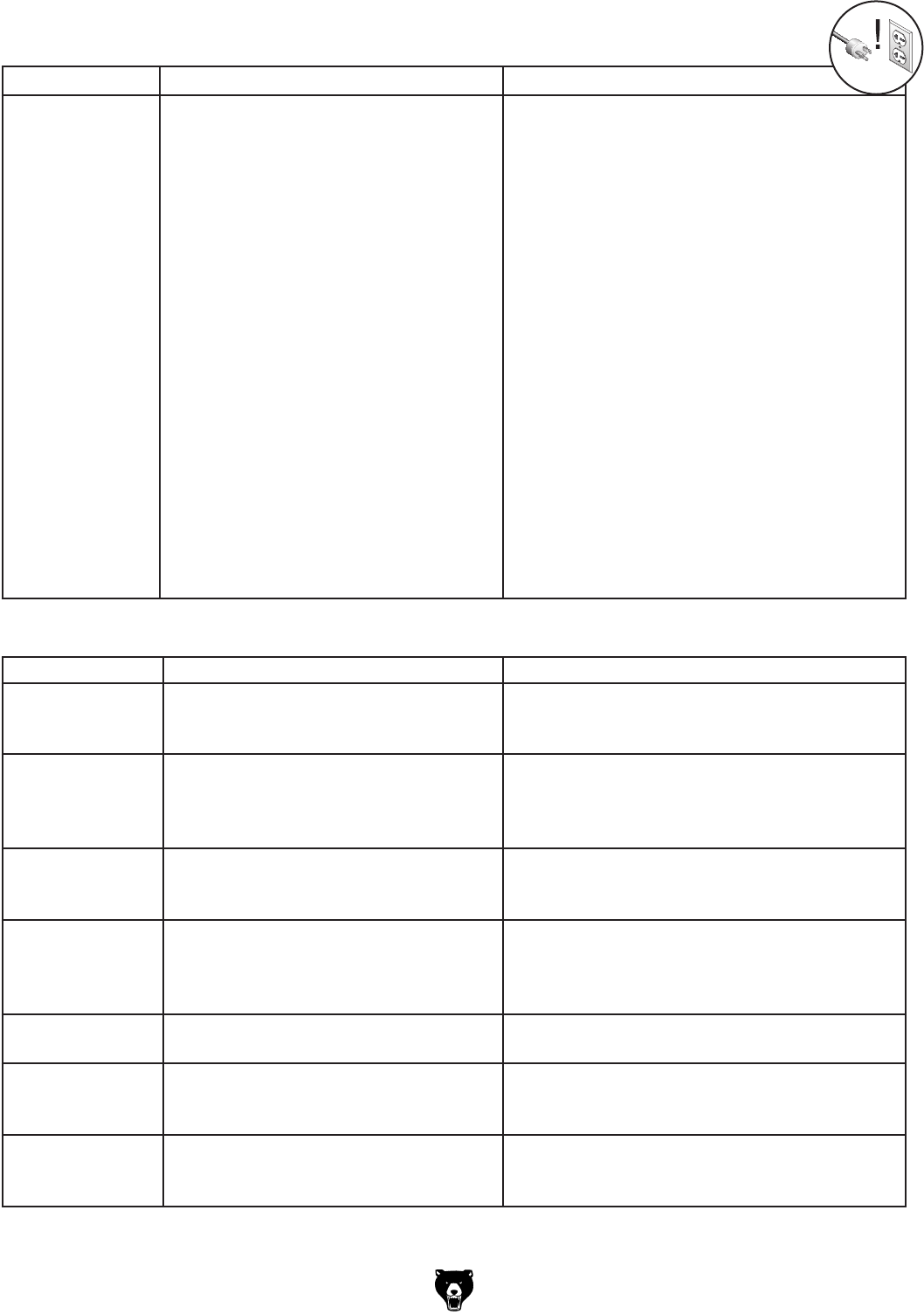

Symptom Possible Cause Possible Solution

Motor stalls or is

overloaded.

1. Sanding depth too aggressive.

2. Workpiece material is not suitable for this

machine.

3. Conveyor speed too fast for task.

4. Dust collection ducting is poor.

5. Air pressure brake solenoid is at fault.

6. Run capacitor is at fault.

7. Conveyor speed dial is at fault.

8. Motor connection is wired incorrectly.

9. Plug/receptacle is at fault.

10. Motor bearings are at fault.

11. Machine is undersized for the task.

12. Motor has overheated.

13. Contactor not getting energized or has poor

contacts.

14. Motor is at fault.

15. Centrifugal switch is at fault.

1. Reduce sanding depth or install coarser sandpaper.

2. Only sand wood products; make sure moisture con

-

tent is below 20% and there are no foreign materials

in the workpiece.

3. Decrease conveyor speed (feed rate).

4. Seal all leaks, size ducts correctly, eliminate bends,

and refer to Dust Collection Basics Handbook (ISBN

0-9635821-2-7) for further recommendations.

5. Test/replace.

6. Test/replace.

7. Test and replace if faulty.

8. Correct motor wiring connections.

9. Test for good contacts; correct the wiring.

10. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

11. Use new sandpaper with appropriate grit; reduce the

feed rate/depth of sanding.

12. Clean off motor, let cool, and reduce workload.

13. Test for power on all legs and contactor operation.

Replace if faulty.

14. Test/repair/replace.

15. Adjust/replace centrifugal switch if available.

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Grit rubs off the belt

easily.

1. Sanding belt has been stored in an incor

-

rect environment.

2. Sanding belt has been folded or smashed.

1. Store sanding belt away from extremely dry or hot

temperatures.

2. Store sanding belt flat, not folded or bent.

Sanding surfaces

clog quickly or burn.

1. Sanding depth too aggressive.

2. Sanding softwood.

1. Reduce sanding depth or install coarser sandpaper.

2. Use different stock. Or, accept the characteristics

of the stock and plan on cleaning/replacing belts

frequently.

Burn marks on

workpiece.

1. Using too fine of sanding grit.

2. Sanding depth too aggressive.

3. Work held still for too long.

1. Use a coarser grit sanding belt.

2. Reduce sanding depth or install coarser sandpaper.

3. Do not keep workpiece in one place for too long.

Glazed sanding sur

-

faces.

1. Sanding wet stock.

2. Sanding stock with high residue.

1. Dry stock properly before sanding.

2. Use different stock. Or, accept the characteristics

of the stock and plan on cleaning/replacing sanding

belts frequently.

Workpiece slips on

conveyor belt.

1. Dirty conveyor belt.

2. Conveyor belt is worn.

1. Clean conveyor belt.

2. Replace conveyor belt.

Uneven thickness

from left to right of

board.

1. Sanding drum not parallel to conveyor.

2. Conveyor belt is worn.

1. Adjust the conveyor to sanding drum parallelism

(Page 32).

2. Replace conveyor belt.

Machine is loud,

overheats or bogs

down in the cut.

1. Excessive depth of cut.

2. Dull sanding belt.

1. Decrease depth of cut.

2. Replace sanding belt.

Sanding Operation