G0644 15" Open-End Wide Belt Sander

-35-

5. Place the sanded workpiece under the sand-

ing drum and lower the sanding cabinet

until the sanding drum is just touching the

workpiece.

6. Remove the workpiece from under the sand-

ing drum and position it directly under the

depth of cut safety bar.

7. Loosen the three hex bolts securing the

safety bar.

8. Use feeler gauges to raise the safety bar

approximately

3

⁄64" (0.047") above the

workpiece from side-to-side.

9. Re-tighten the hex bolts.

10. Re-install the sanding belt and secure the

access door.

Adjusting Pressure

Rollers

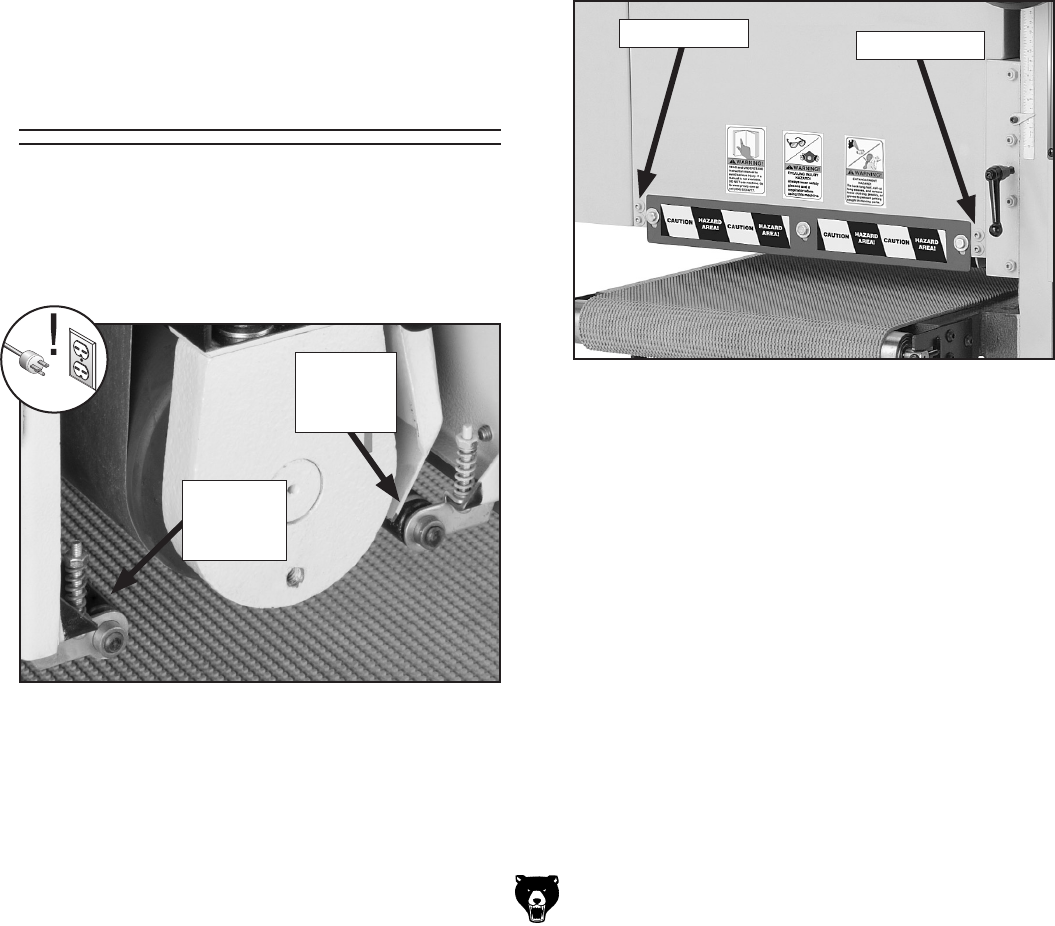

The height of the pressure rollers (see Figure

38

) is set below the sanding drum to keep the

workpiece firmly against the conveyor belt as it

passes through the sander, preventing workpiece

kickback.

The pressure roller height was factory set at

approximately

1

⁄16" (0.063") below the lowest point

of the sanding drum.

To adjust the height of the pressure rollers:

1. Make sure the sanding drum and conveyor

are parallel (

Page 32).

2. Sand a 15" wide piece of stock until it is flat.

3. DISCONNECT THE SANDER FROM

POWER!

4. Open the sanding belt access door and

remove the sanding belt from the sander.

5. Loosen the eight cap screws securing the

front and rear pressure rollers to the sanding

cabinet (see

Figure 39).

Figure 38. Pressure rollers.

Rear

Pressure

Roller

Front

Pressure

Roller

6. Place the workpiece under the sanding

drum.

7. Use feeler gauges to position the sanding

drum approximately

1

⁄16" (0.063") above the

sanded workpiece from Step 2

.

8. Adjust the pressure rollers so that they are

lightly resting on the workpiece from side-to-

side, then re-tighten the cap screws to secure

the pressure rollers in place.

9. Re-install the sanding belt and secure the

access door.

adjusting pressure rollers

Figure 39. Pressure roller cap screws (front

pressure roller cap screws shown)

Cap Screws

Cap Screws