-32-

G0644 15" Open-End Wide Belt Sander

Conveyor Belt

Tracking

If the conveyor belt tracks to either side, the

belt could become damaged and have to be

replaced.

Adjusting the conveyor belt tracking is a balancing

process that takes patience and some trial-and-

error. You must tighten the loose side adjusting

bolt (the side the belt is tracking towards) to make

the belt move to the middle of the rollers, then

loosen that same adjusting bolt to make the con

-

veyor stay in position.

To adjust the conveyor belt tracking:

1. Make sure the conveyor is properly tensioned

(Page 30).

1. Turn the conveyor ON and watch it track.

2. Determine which side the conveyor belt is

tracking towards, and tighten the adjustment

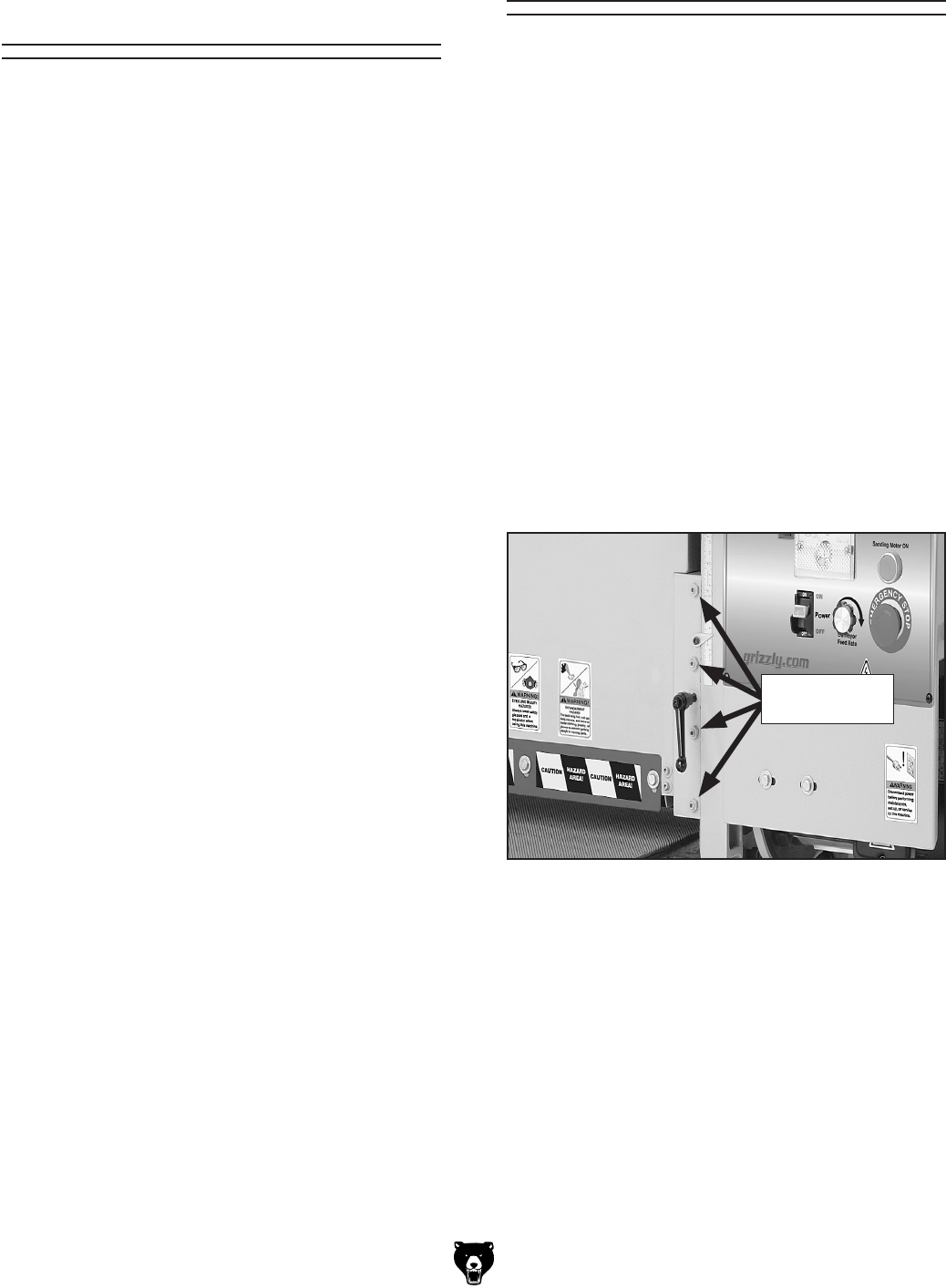

bolt (see

Figure 32) on that side until the belt

tracks in the opposite direction.

Note: Tracking changes may take a couple of

minutes before they are noticeable.

3. When the conveyor belt is near the middle

of the rollers, loosen the same adjusting bolt

until the conveyor stops moving to the side

and tracks straight.

— If the belt tracks too far to the other side,

tighten the adjusting bolt as necessary to

bring it back, then repeats Steps 2 & 3 until

the tracking is correct.

conveyor tracking

Gib Adjustment

The gib controls the accuracy of sanding cabinet

movement along the dovetail way. A tight gib

makes the movement more accurate, but harder

to move, and will lead to premature wear of the

ways. A loose gib makes the movements and

measurements sloppy, but easier to move. The

goal of gib adjustment is to remove unnecessary

sloppiness without causing the dovetail way to

bind.

To adjust the gib:

1. DISCONNECT THE SANDER FROM

POWER!

2. Clean and lubricate the dovetail way and

gears (

Page 26).

3. Loosen the four gib jam nuts along the col-

umn shown in

Figure 34.

4. Adjust the gib set screws evenly until there is

a slight drag on the dovetail way as you move

the sanding cabinet up and down.

5. Re-tighten the gib jam nuts.

Figure 34. Gib jam nuts and set screws.

Gib Jam Nuts

& Set Screws

gib adjustment