ACCESSORIES

M104

DUAL SPINDLE SECTION

32

DISASSEMBLY

REASSEMBLY

The dual spindle attachment can be serviced without removing

the complete assembly from the tool. Using the 4 mm hex wrench

supplied with the unit, loosen both adjusting screws (45992) -

NOTE: Alternately unthread adjusting screws approximately 1/2

turn at a time or unthread screws simultaneously to prevent dam-

aging the unit.

Pack bearings and coat gears with a good grade of bearing

grease when assembling. Saturate oil reservoirs with a good mul-

tigrade 10W/30 oil.

After the body and components have been removed from the

adapter, driving spindle (47757-302) and components can be re-

moved from adapter. To remove bearing (32325) and/or gear

(45991); remove retaining ring (45989), press bearing back on

spindle to expose needle roller (45986) and remove roller to re-

move gear. Remove bearing from spindle.

Insert a dummy adjusting screw (45992) (or a shaft of the same

diameter) thru adapter side of body to maintain alignment of parts

to be assembled into body and assemble nylon washer (45994) to

dummy screw. Assemble one bearing (46002), spacer (46995)

and another bearing (46002) into gear (45996) and assemble

gear to the dummy screw. Assemble nylon washer (45993) into

body, bending washer slightly to insert into body, and assemble oil

reservoir (46009) into body.

To remove gear (45996) and/or components, remove crescent

ring (45997). Rotate spindle turret, and at the same time, pull back

slightly on turret to locate alignment of spindle with notch in body

(45999) and remove spindle assembly from body. To remove gear

(45996) from body, remove oil reservoir (46009) and nylon wash-

er (45993) bending washer slightly to remove. Bearings (46602),

spacer (45995) and washer (45994) are loose parts and will drop

out. Do not disassemble spindle (46022). If necessary to replace

a part, replace as complete spindle assembly (46022).

Assemble adjusting screw to spindle assembly (46022) and as-

semble nylon washer (45994) to adjusting screw. Assemble the

spindle assembly into body while holding adjusting screw in align-

ment with dummy screw to maintain pans alignment and using

adjustment screw to push the dummy screw out of body. NOTE:

Align spindle assembly with notch in body to assemble. After as-

sembling spindle to body, assemble crescent ring (45997) to ad-

justing screw, securing screw to body.

Reassemble driving spindle (47757-302) and components and

the body (45999) and spindle assemblies (46022) to adapter

(47757-298) in the reverse manner of disassembly.

RECOMMENDED METHOD FOR HOLDING DRILLS IN SPINDLES

To properly hold drill bit in Collet and reduce the chance of slip-

page, a flat must be ground on the shank end of the bit. The flat

Insert bit into spindle and into locking insert (where applicable) in-

should be approximately 5/16” (8 mm) long and the depth should

suring that one of the set screws locates squarely on the flat of the

be 1/3 of the bit diameter. NOTE: If bit is too large to fit into locking

bit. Tighten Collet firmly, then tighten set screws. NOTE: DO NOT

insert (smaller capacity dual spindles do not have insert), a

overtighten Collet. NOTE: Intent of set screws is only to keep bit

square must be around onto the shank end of the bit.

from turning in Collet.

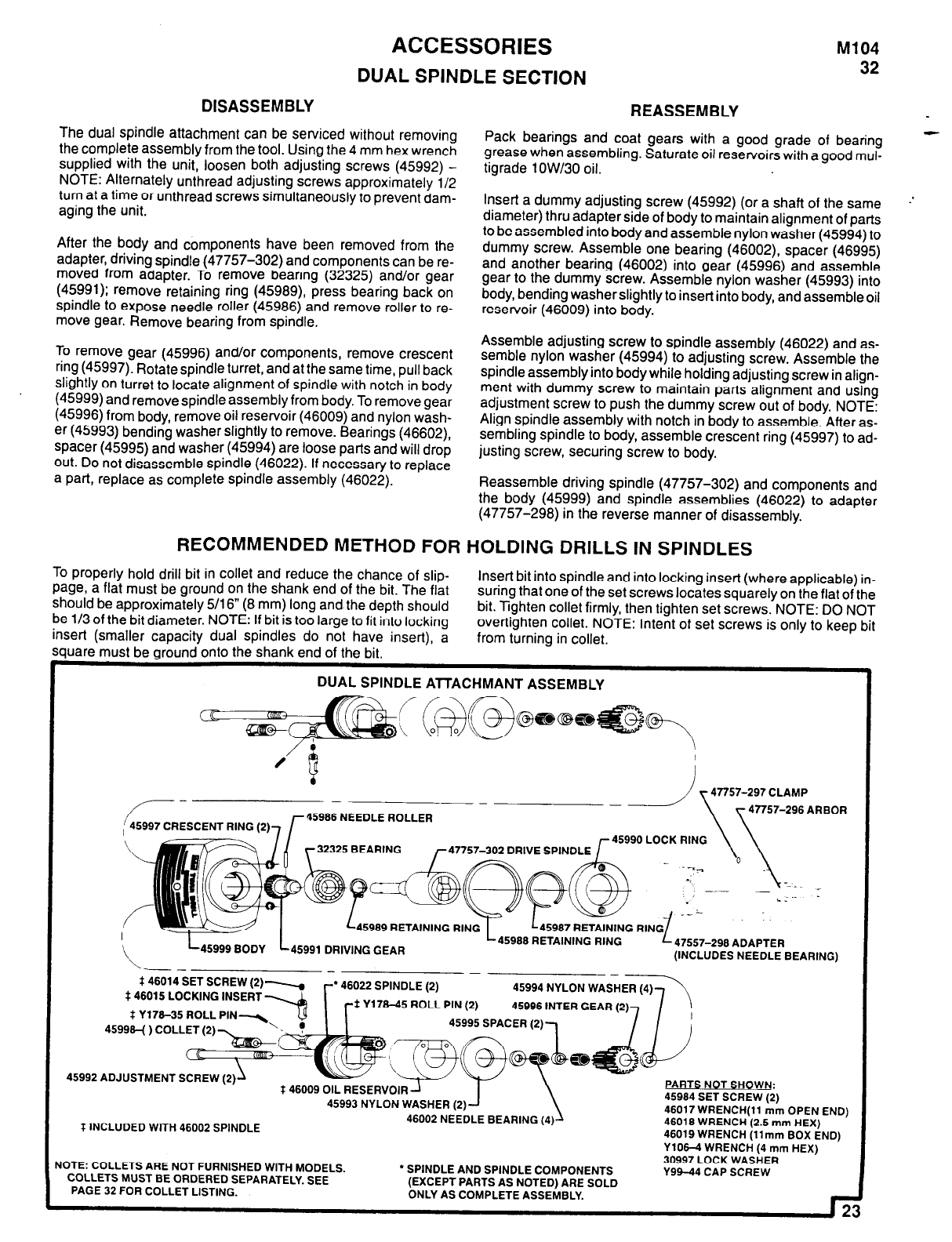

DUAL SPINDLE ATTACHMANT ASSEMBLY

45986 NEEDLE ROLLER

47757-297 CLAMP

47757-296

ARBOR

989 RETAINING

RING

45980

45991 DRIVING GEAR

RETAINING

RING

47557-290 ADAPTER

(INCLUDES NEEDLE BEARING)

-

l

46022 SPINDLE (2)

45994 NYLON WAS

Y178-45 ROLL PIN (2) 45996 INTER GEAR (

45995 SPACER (2)

$46014 SET SCREW (2)

$46015 LOCKING INSERT

$ Y176-35 ROLL

45998-( ) COLLET (2)

45992 ADJUSTMENTS

$46009 OIL RESERVOIR

PARTS NOT SHOWN:

45993 NYLON WASHER (2)

45984 SET SCREW (2)

46017 WRENCH(11 mm OPEN END)

$ INCLUDED WITH 46002 SPINDLE

46002 NEEDLE BEARING (4)

46018 WRENCH (2.5 mm HEX)

46019 WRENCH (11mm BOX END)

Y106-4 WRENCH (4 mm HEX)

NOTE: COLLETS ARE NOT FURNISHED WITH MODELS.

l

SPINDLE AND SPINDLE COMPONENTS

30997 LOCK WASHER

Y99-44 CAP SCREW

CoLLETs MUST

BE ORDERED SEPARATELY. SEE

PAGE 32 FOR COLLET LISTING.

(EXCEPT PARTS AS NOTED) ARE SOLD

ONLY AS COMPLETE ASSEMBLY.

23