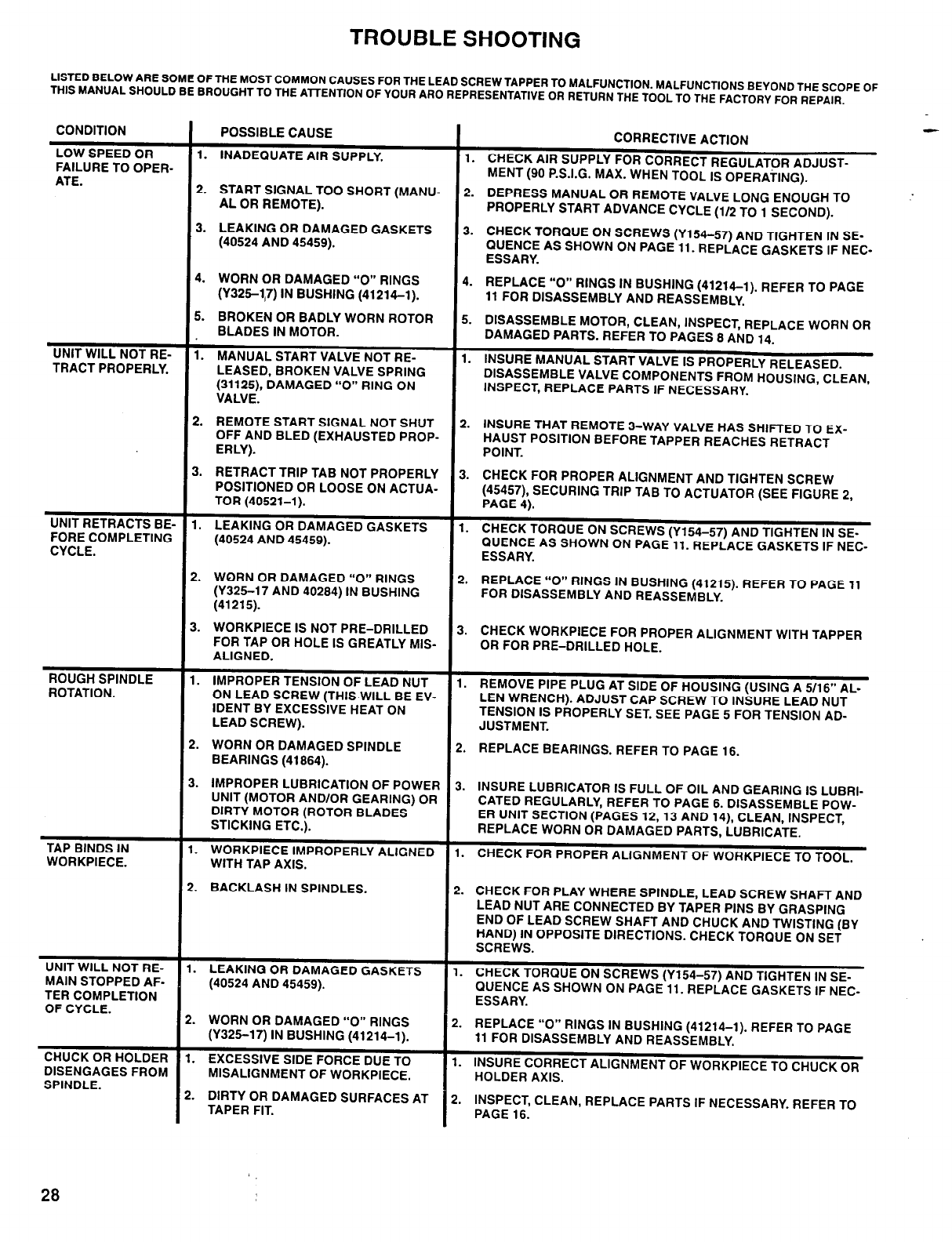

TROUBLE SHOOTING

LISTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE LEAD SCREW TAPPER TO MALFUNCTION. MALFUNCTIONS BEYOND THE SCOPE OF

THIS MANUAL SHOULD BE BROUGHT TO THE ATTENTlON OF YOUR ARO REPRESENTATIVE OR RETURN THE TOOL TO THE FACTORY FOR REPAIR.

CONDITION

LOW SPEED OR

FAILURE TO OPER-

ATE.

UNIT WILL NOT RE-

TRACT PROPERLY.

UNIT RETRACTS BE-

FORE COMPLETING

CYCLE.

ROUGH SPINDLE

ROTATION.

TAP BINDS IN

WORKPIECE.

UNIT WILL NOT RE-

MAIN STOPPED AF-

TER COMPLETION

OF CYCLE.

CHUCK OR HOLDER

DISENGAGES FROM

SPINDLE.

POSSIBLE CAUSE

1. INADEQUATE AIR SUPPLY.

2.

START SIGNAL TOO SHORT (MANU-

AL OR REMOTE).

3.

LEAKING OR DAMAGED GASKETS

(40524 AND 45459).

4.

WORN OR DAMAGED “0” RINGS

(Y325-17) IN BUSHING (41214-1).

5.

BROKEN OR BADLY WORN ROTOR

BLADES IN MOTOR.

1.

MANUAL START VALVE NOT RE-

LEASED, BROKEN VALVE SPRING

(31125), DAMAGED “0” RING ON

VALVE.

2.

REMOTE START SIGNAL NOT SHUT

OFF AND BLED (EXHAUSTED PROP-

ERLY).

3.

RETRACT TRIP TAB NOT PROPERLY

POSITIONED OR LOOSE ON ACTUA-

TOR (40521-1).

1. LEAKING OR DAMAGED GASKETS

(40524 AND 45459).

2.

WORN OR DAMAGED “0” RINGS

(Y325-17 AND 40264) IN BUSHING

(41215).

3.

WORKPIECE IS NOT PRE-DRILLED

FOR TAP OR HOLE IS GREATLY MIS-

ALIGNED.

1.

IMPROPER TENSION OF LEAD NUT

ON LEAD SCREW (THIS WILL BE EV-

IDENT BY EXCESSIVE HEAT ON

LEAD SCREW).

2.

WORN OR DAMAGED SPINDLE

BEARINGS (41864).

3.

IMPROPER LUBRICATION OF POWER

UNIT (MOTOR AND/OR GEARING) OR

DIRTY MOTOR (ROTOR BLADES

STICKING ETC.).

1. WORKPIECE IMPROPERLY ALIGNED

WITH TAP AXIS.

2. BACKLASH IN SPINDLES.

1. LEAKING OR DAMAGED GASKETS

(40524 AND 45459).

2.

WORN OR DAMAGED “0” RINGS

(Y325-17) IN BUSHING (41214-1).

1.

EXCESSIVE SIDE FORCE DUE TO

MISALIGNMENT OF WORKPIECE.

2.

DIRTY OR DAMAGED SURFACES AT

TAPER FIT.

CORRECTIVE ACTION

1.

CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUST-

MENT (90 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

2.

DEPRESS MANUAL OR REMOTE VALVE LONG ENOUGH TO

PROPERLY START ADVANCE CYCLE (1/2 TO 1 SECOND).

3.

CHECK TORQUE ON SCREWS (Y154-57) AND TIGHTEN IN SE-

QUENCE AS SHOWN ON PAGE 11. REPLACE GASKETS IF NEC-

ESSARY.

4.

REPLACE “0” RINGS IN BUSHING (41214-1). REFER TO PAGE

11 FOR DISASSEMBLY AND REASSEMBLY.

5.

DISASSEMBLE MOTOR, CLEAN, INSPECT, REPLACE WORN OR

DAMAGED PARTS. REFER TO PAGES 8 AND 14.

1.

INSURE MANUAL START VALVE IS PROPERLY

RFI FASFD

-. ..---_.---.

DISASSEMBLE VALVE COMPONENTS FROM HOUSING, CLEAN,

INSPECT, REPLACE PARTS IF NECESSARY.

2.

INSURE THAT REMOTE 3-WAY VALVE HAS SHIFTED TO EX-

HAUST POSITION BEFORE TAPPER REACHES RETRACT

POINT.

3.

CHECK FOR PROPER ALIGNMENT AND TIGHTEN SCREW

(45457), SECURING TRIP TAB TO ACTUATOR (SEE FIGURE 2,

PAGE 4).

I.

CHECK TORQUE ON SCREWS (Y154-57) AND TIGHTEN IN SE-

QUENCE AS SHOWN ON PAGE 11. REPLACE GASKETS IF NEC-

ESSARY.

2.

REPLACE “0” RINGS IN BUSHING (41215). REFER TO PAGE 11

FOR DISASSEMBLY AND REASSEMBLY.

3.

CHECK WORKPIECE FOR PROPER ALIGNMENT WITH TAPPER

OR FOR PRE-DRILLED HOLE.

1.

REMOVE PIPE PLUG AT SIDE OF HOUSING (USING A 5/16” AL-

LEN WRENCH). ADJUST CAP SCREW TO INSURE LEAD NUT

TENSION IS PROPERLY SET. SEE PAGE 5 FOR TENSION AD-

JUSTMENT.

2.

REPLACE BEARINGS. REFER TO PAGE 16.

3.

INSURE LUBRICATOR IS FULL OF OIL AND GEARING IS LUBRI-

CATED REGULARLY, REFER TO PAGE 6. DISASSEMBLE POW-

ER UNIT SECTION (PAGES 12,13 AND 14), CLEAN, INSPECT,

REPLACE WORN OR DAMAGED PARTS, LUBRICATE.

1.

CHECK FOR PROPER ALIGNMENT OF WORKPIECE TO TOOL.

2.

CHECK FOR PLAY WHERE SPINDLE, LEAD SCREW SHAFT AND

LEAD NUT ARE CONNECTED BY TAPER PINS BY GRASPING

END OF LEAD SCREW SHAFT AND CHUCK AND TWISTING (BY

HAND) IN OPPOSITE DIRECTIONS. CHECK TORQUE ON SET

SCREWS.

I.

CHECK TORQUE ON SCREWS (Y154-57) AND TIGHTEN IN SE-

QUENCE AS SHOWN ON PAGE 11. REPLACE GASKETS IF NEC-

ESSARY.

2.

REPLACE “0” RINGS IN BUSHING (41214-1). REFER TO PAGE

11 FOR DISASSEMBLY AND REASSEMBLY.

I.

INSURE CORRECT ALIGNMENT OF WORKPIECE TO CHUCK OR

HOLDER AXIS.

2.

INSPECT, CLEAN, REPLACE PARTS IF NECESSARY. REFER TO

PAGE 16.

28