AIR AND LUBE REQUIREMENTS

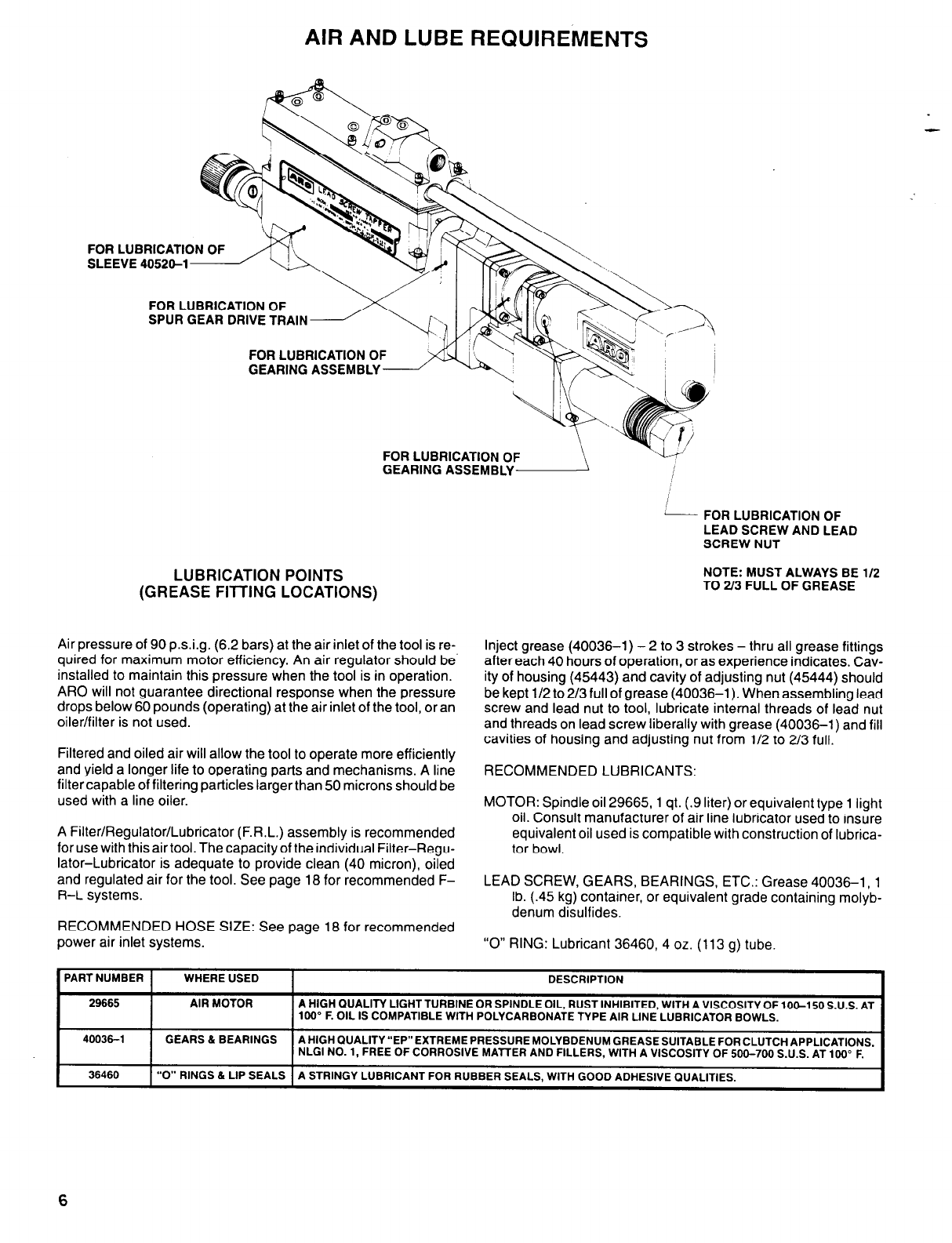

FOR LUBRICATION OF

GEARING ASSEMBLY

FOR LUBRICATION OF

GEARING ASSEMBLY

LUBRICATION POINTS

(GREASE FITTING LOCATIONS)

Air pressure of 90 p.s.i.g. (6.2 bars) at the air inlet of the tool is re-

quired for maximum motor efficiency. An air regulator should be’

installed to maintain this pressure when the tool is in operation.

ARO will not guarantee directional response when the pressure

drops below 60 pounds (operating) at the air inlet of the tool, or an

oiler/filter is not used.

Filtered and oiled air will allow the tool to operate more efficiently

and yield a longer life to operating parts and mechanisms. A line

filter capable of filtering particles larger than 50 microns should be

used with a line oiler.

A Filter/Regulator/Lubricator (F.R.L.) assembly is recommended

for use with this air tool. The capacity of the individual Filter-Regu-

lator-Lubricator is adequate to provide clean (40 micron), oiled

and regulated air for the tool. See page 18 for recommended F-

R-L systems.

RECOMMENDED HOSE SIZE: See page 18 for recommended

power air inlet systems.

- FOR LUBRICATION OF

LEAD SCREW AND LEAD

SCREW NUT

NOTE: MUST ALWAYS BE 1/2

TO 2/3 FULL OF GREASE

Inject grease (40036-1) - 2 to 3 strokes - thru all grease fittings

after each 40 hours of operation, or as experience indicates. Cav-

ity of housing (45443) and cavity of adjusting nut (45444) should

be kept 1/2 to 2/3 full of grease (40036-1). When assembling lead

screw and lead nut to tool, lubricate internal threads of lead nut

and threads on lead screw liberally with grease (40036-1) and fill

cavities of housing and adjusting nut from 1/2 to 2/3 full.

RECOMMENDED LUBRICANTS:

MOTOR: Spindle oil 29665, 1 qt. (.9 liter) or equivalent type 1 light

oil. Consult manufacturer of air line lubricator used to insure

equivalent oil used is compatible with construction of lubrica-

tor bowl.

LEAD SCREW, GEARS, BEARINGS, ETC.: Grease 400361,1

lb. (.45 kg) container, or equivalent grade containing molyb-

denum disulfides.

“0” RING: Lubricant 36460, 4 oz. (113 g) tube.

PART NUMBER WHERE USED

29665

AIR MOTOR

DESCRIPTION

A HIGH QUALITY LIGHT TURBINE OR SPINDLE OIL, RUST INHIBITED, WITH A VISCOSITY OF 100-150 S.U.S. AT

100” F. OIL IS COMPATIBLE WITH POLYCARBONATE TYPE AIR LINE LUBRICATOR BOWLS.

40036-1 GEARS & BEARINGS

A HlGH QUALlTY “EP” EXTREME PRESSURE MOLYBDENUM GREASE SUlTABLE FOR CLUTCH APPLICATIONS,

NLGI NO. 1, FREE OF CORROSIVE MATTER AND FILLERS, WITH A VISCOSITY OF 500-700 S.U.S. AT 100” F.

36460 “0” RINGS & LIP SEALS

A STRINGY LUBRICANT FOR RUBBER SEALS, WITH GOOD ADHESIVE QUALITIES.

6