A-5

INSTALLATION

MAXsa™ 10 CONTROLLER

A-5

Auxiliary Input Power Connection Instructions

Use the appropriate size leads, at least 14 AWG – 2

wire with ground.

1. Remove two Phillips Head screws on right side of

front panel of hinged door to access terminal strip.

2. Remove a plug button and install a box connector

to provide strain relief for the input power leads.

3. Strip off 1/4”(6.4mm) of insulation from the leads

and route them through the strain relief

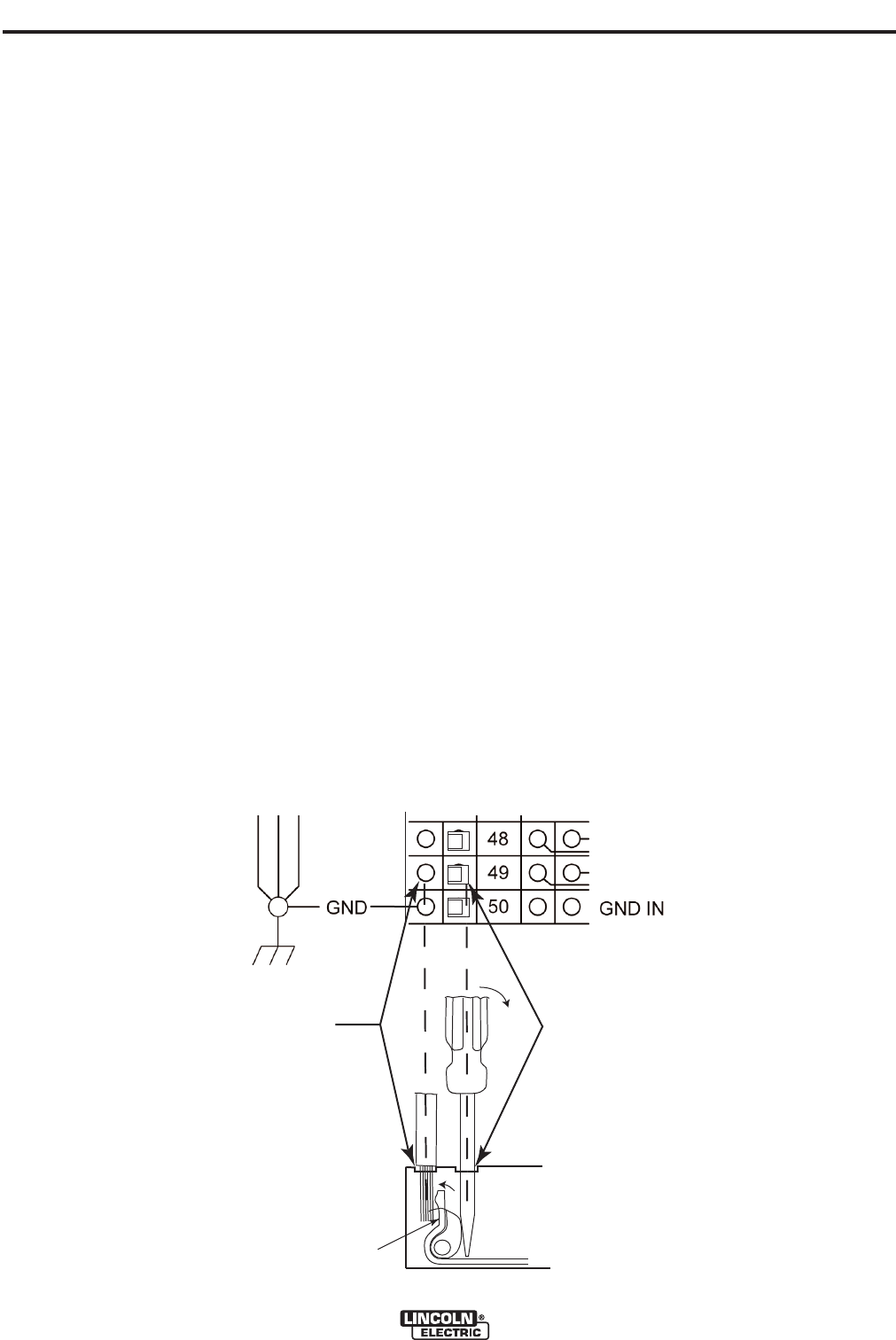

4. Locate the 4-terminal blocks, numbered #48, #49,

and #50. These are to be used to bring in auxiliary

power. Terminal block #50 is used for the input

ground connection. This terminal block is color-

coded green and yellow for easy identification.

Terminal blocks #48 and #49 are to be used to con-

nect the input power circuit. (See Figure A.3).

5. Using a flat-head screwdriver with a blade dimen-

sion of 0.137"(3.5mm) x 0.020"(.51mm), insert the

screwdriver into the square hole next to the mount-

ing hole to be used on the terminal strip. The

screwdriver should be inserted until it bottoms out.

This opens the screwless cage clamping style wire

insertion port. With the cage clamp opened insert

the wire into the round port until it bottoms out.

While holding the lead securely, remove the screw-

driver from the terminal block. This closes the cage

clamp onto the lead holding it securely. Any open

port on blocks #48, #49, and #50 may be used.

Terminal blocks 48 and 49 are shipped connected to

the contacts of CR2 and CR3 by leads 531 and 532.

These relay contacts are also connected to the 4-pin

Travel connector and the 3-pin Flux connector located

on the bottom of the MAXsa™ 10 CONTROLLER.

CR1 is available for a separate customer connection,

but it will turn ON and OFF with CR2. Therefore, if

Lincoln auxiliary equipment is to be used, connecting

115VAC to the terminal strip is all that is required to

power the devices.

NOTE: The contacts of CR1 are not connected to ter-

minals #48 and #49 when shipped. Applying

power to the #48 and #49 terminals will not

transfer voltage to the CR1 relay. Connect

leads from the #48 terminal to the #4 terminal

and from the #49 terminal to the #3 terminal to

supply power to the common contacts of the

relay.

Once input power is applied to the terminal strip, this

voltage is always on terminal strip blocks #3, #4 (if

connected), #11, #17, and #18. These are the inputs

to the solid-state relay contacts. Input voltage is also

present on terminal strip blocks #7, #8 (if connected),

#15, #21, and #22 due to the N.C. contacts on the

relays. When the CR1 relay is energized, input power

is transferred to terminal strip blocks #5 and #6 (if

connected). When the CR2 relay is energized, input

power is transferred to terminal strip block #13. When

the CR3 relay is energized, input power is transferred

to terminal strip blocks #19 and #20. CR1 and CR2

will be turned ON and OFF at the same time.

INSERT

WIRE HERE

INSERT SCREW

DRIVER HERE

# 1

# 3

REMOVE SCREW

DRIVER FROM CAGE

CLAMP HOLE.

# 2

CAGE CLAMP

VAC IN

NEUTRAL (31)

VAC IN

LINE (32)

FIGURE A.3