B-6

OPERATION

B-6

MULTIPLE ARC CONFIGURATION

Power Wave

®

AC/DC 1000 SD / MAXsa™ systems

can be used in multiple arc set ups with up to six arcs.

To minimize magnetic interaction between the arcs, it

is imperative that they be phased correctly. Phasing is

essentially a time offset between the waveforms of dif-

ferent arcs. The phase of each arc is set via the User

Interface of the lead arc.

The ideal situation is to have adjacent arcs 90° offset

as illustrated in table B.1.

See the Power Wave

®

AC/DC Operator’s Manual for

more information regarding the configuration of multi-

ple arc systems.

MAXsa™ 10 CONTROLLER

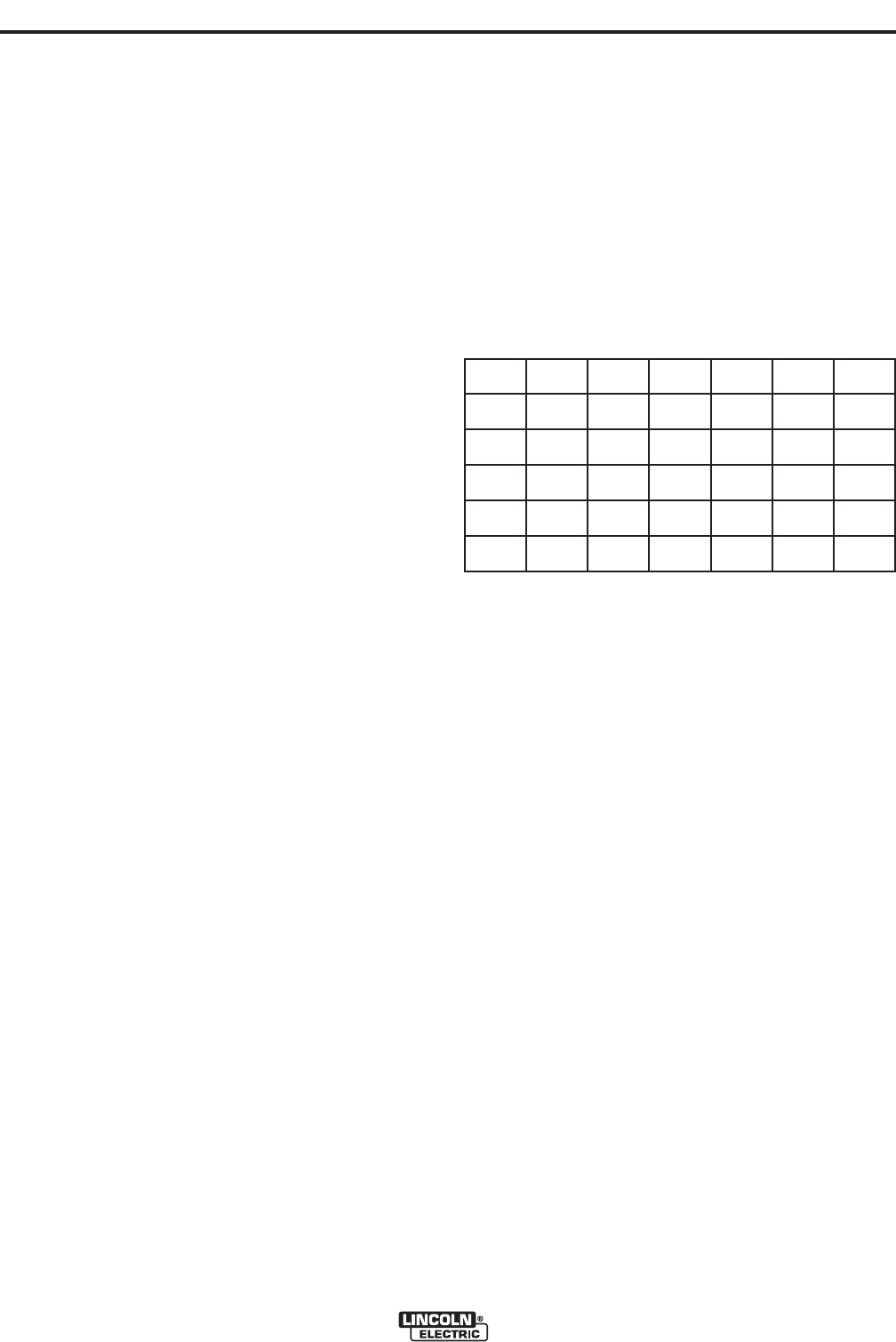

TABLE B.1 - PHASE RELATIONSHIP

ARC 1 ARC 2 ARC 3 ARC 4 ARC 5 ARC 6

2 Arc

System

0° 90° X X X X

3 Arc

System

0° 90° 180° X X X

4 Arc

System

0° 90° 180° 270° X X

5 Arc

System

0° 90° 180° 270° 0° X

6 Arc

System

0° 90° 180° 270° 0° 90°

WELD MODE SEARCHING

The Weld Mode Search feature allows the selection of

a welding mode based on certain criteria (wire size,

process type, etc.).

SEARCHING FOR A WELD MODE

To search for a mode, press and release the control

knob while the WELD MODE indicator is lit. Another

way to search for a mode is to turn the control knob

until “Weld Mode Search” is displayed. This will

appear in between the highest and the lowest weld

mode number.

Once “Weld Mode Search” is displayed, pressing the

right pushbutton labeled “Begin” will start the search

process.

During the search process, pressing the right pushbut-

ton typically acts as a “next” button and the left push-

button typically acts as a “back” button. Pressing the

control knob also acts as a “next” button.

Rotate the control knob then press to select relevant

welding details such as welding process, wire type,

wire size, etc.

When the final selection is made, the MAXsa™ 10 will

automatically change to the weld mode found by the

Weld Mode Search process.

Earlier products may not have this feature. To acti-

vate this feature, a software update may be needed

from www.powerwavesoftware.com