E-5

TROUBLESHOOTING

E-5

SYNERGIC 7 & 7H

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

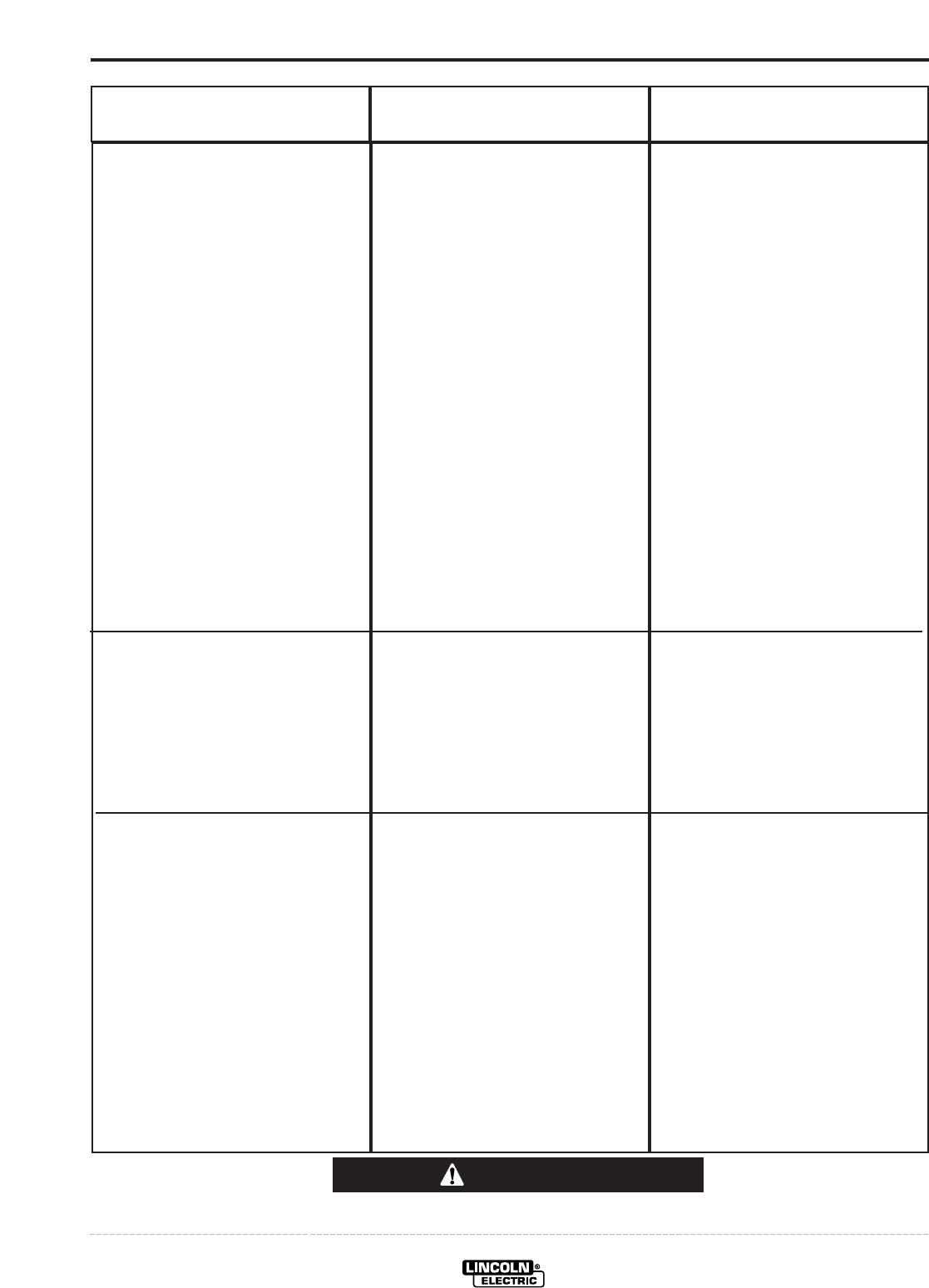

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

9. Wire feed motor runs and solenoid

turns on but no arc voltage pre-

sent.

10. Speed does not change when

weld current flows.

11. Voltmeter does not function or

read properly when arc voltage is

present.

a. Power source is defective.

b. Input cable is defective.

c. Wiring harness or Control PC

board is defective.

a. Run-in and weld speeds are set

to the same value or run-in is set

to ---.

b. Power Source may be defective

or there may be a problem with

the Serial communications.

a. Electrode sensing lead or connec-

tions may be intermittent.

b. Serial communication problem.

a. If arc voltage is present when wire feeder is

connected to the other input receptacle (#1 or

#2) of power source then power source is

defective. Otherwise, select a stick procedure

on power source, connect a known good input

cable (see step b) to wire feeder #1 receptacle

of power source, and jumper across sockets C

and D of 8-socket input cable plug. If no arc

voltage is present (refer to display on power

source) then power source is defective.

b. Disconnect input cable from power source and

wire feeder. Check continuity between socket

C of 8-socket plug and pin C of 14-pin plug of

the input cable, and between socket D of 8-

socket plug and pin D of 14-pin plug of the

input cable. Replace cable if no continuity.

c. Check continuity between pin C of 8-pin recep-

tacle and pin 7 of plug P1, and between pin D

of 8-pin receptacle and pin 6 of plug P1. If no

continuity then harness is faulty, otherwise

replace Control PC board. (See procedure for

replacing PC boards.)

a. Set run-in and weld speeds to desired set-

tings.

b. Make sure that parameters on power source

display, such as WFS, match those on wire

feeder display. If not, refer to Problem 14.

Otherwise, replace control PC board. (See

procedure for replacing PC boards.)

a. Check continuity from brass block on wire

feeder to pin F of 8-pin control cable recepta-

cle on wire feeder. If there is no continuity,

repair faulty connection.

b. Make sure that parameters on power source

display, such as WFS, match those on wire

feeder display. If not, refer to Problem 14.

Otherwise, replace Control PC board. (See

procedure for replacing PC boards.)