A-2

INSTALLATION

SYNERGIC 7 & 7H

A-2

GENERAL DESCRIPTION

The Synergic 7 is a semiautomatic constant speed wire

feeder designed specifically for use with the Invertec Power

Wave type power sources. A serial communication link is

supplied through the control cable of the Synergic 7

enabling information to be shared between the power

source and wire feeder. The Synergic 7 comes factory

equipped with a gas solenoid valve with gas fittings and

standard Lincoln gun connector. These models includes a

3-1/2 digit LED display with rotating knob encoder controls

for setting the wire feed speed and voltage and a dual pro-

cedure selector switch. A tactile-feel keypad provides

selection of operating mode, function selection, timer and

crater fill selection and parameter adjustment. Two keys

provide Cold Feed and Gas Purge functions, and connector

receptacles are provided for an optional dual procedure

remote control and dual procedure switch.

The unit has 3 operating modes: 2-step trigger, 4-step trig-

ger and spot. Three functions can be selected: Volts or

Trim Preset/arc (memory) voltmeter, Run-in speed and weld

speed (IPM or m/min.) or (memory) ammeter. In addition,

when 4-step trigger mode is selected, crater fill WFS is also

adjustable. Up to three timers are available depending on

the mode: preflow, postflow and spot, and 5 acceleration

rates are selectable, as well as 6 Burnback settings.

The Synergic 7 is available in 2 models:

b) Feeds .045 - (1.2mm) cored wire for Outershield

GMA or Innershield processes.

Recommended power sources are The Lincoln

Electric Company Synergic type Invertec® Power

Wave power sources with 42VAC auxiliary power, and

a 14-pin connector receptacle.

STANDARD FEATURES

Wire Drive Features:

Wire Drive Unit - Incorporates low voltage permanent

magnet motor and highly efficient two-reduction spur

gearbox which operates in any position. The non-fluid

lubricant won’t leak.

“Quick Release” Wire Feed System - Provides a

completely tool-less means for releasing and opening

the idle roll pressure arm, precisely adjusting the idle

roll pressure and changing the incoming and outgoing

guide tubes and drive rolls.

Drive Rolls and Guide Tubes - Provide long life,

positive feeding and precise alignment of electrode.

Minimizes “birdnest” or mill-thru of wire if properly set.

(Ordered separately.)

Tachometer Feedback - Provides proper wire feed

acceleration and speed accuracy, independent of fluc-

tuations in line voltage and wire loading, for reliable

arc starting and weld consistency.

Run-in Speed Setting - Allows the arc striking speed

“Run-in” to be adjusted independently of the weld feed

speed for starting optimization.

Cold Feed Speed - Provides cold feed speed adjustment

independent of weld, run-in and crater speeds.

Selectable Acceleration - Provides front panel selec-

tion of 5 acceleration rates. This feature in combina-

tion with Run-in Speed provides the ability to easily

optimize starting on any process or procedure.

Solid-State Dynamic Braking -

Quickly stops wire feed

motor to minimize wire overrun during weld termina-

tion. Solid-state design requires no maintenance.

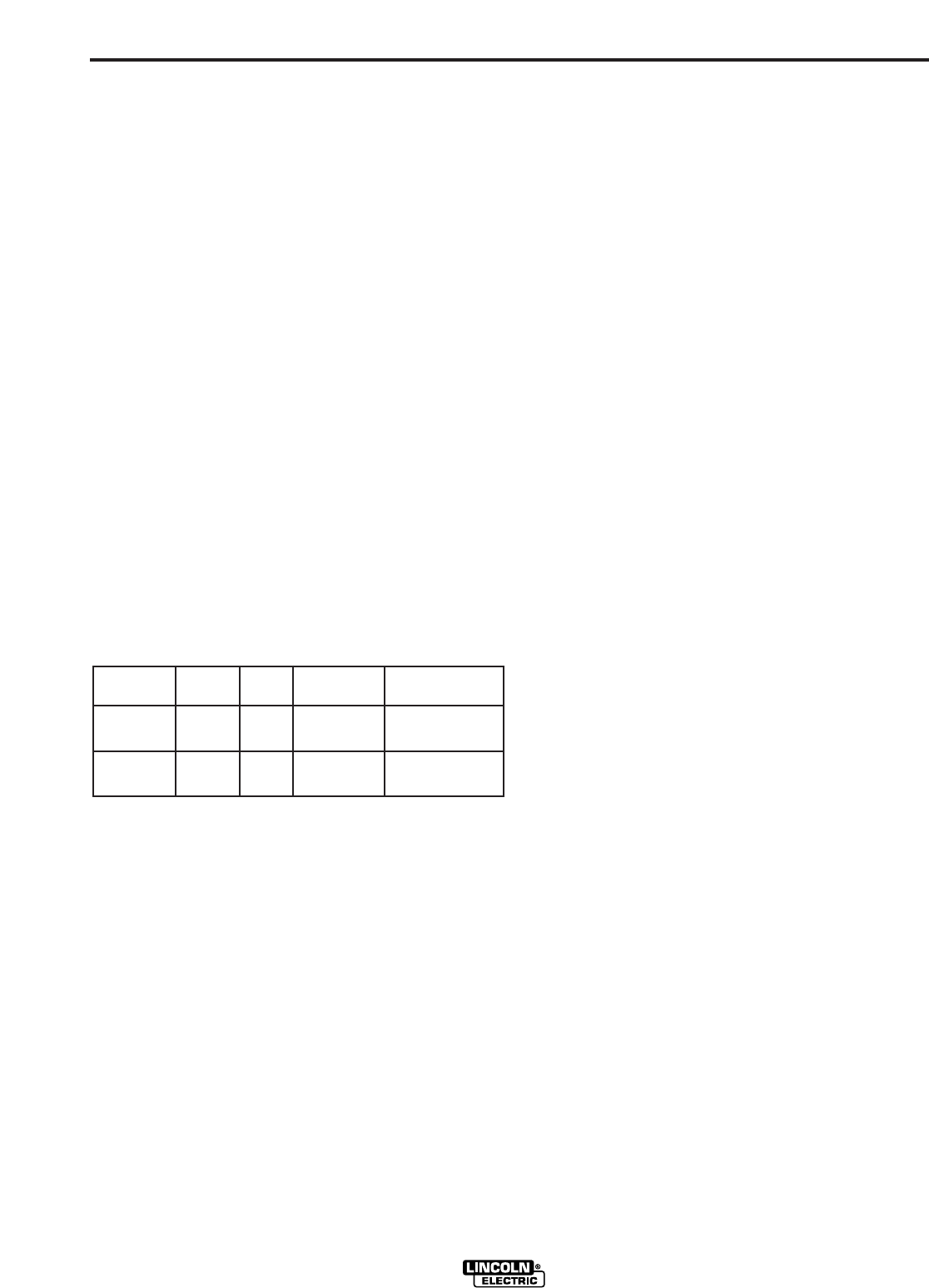

Ordering Speed Range Wire Size Range

Information Model Drive IPM (m/m) IN. (MM)

K631-3 Synergic 4-Roll 50 - 770 .025 - 3/32

7 (1.25 - 19.5) (0.6 - 2.4)

K631-4 Synergic 4-Roll 80 - 1200 .025 - .045

7H (2.00 - 30.5) (0.6 - 1.2)

RECOMMENDED PROCESSES

AND EQUIPMENT

The Synergic 7 wire feed unit has the following wire

feeding capabilities:

a) Feeds .025 - 1/16” (0.6-1.6mm) solid wire for

gas-metal-arc processes.

b) Feeds .045 - 3/32” (1.2-2.4mm) cored wire for Outershield

GMA or Innershield processes up to 5/64” (2.0 mm).

The Synergic 7H wire feed unit has the following wire

feeding capabilities:

a) Feeds .025 - .045” (0.6-1.2mm) solid wire for

gas-metal-arc processes.