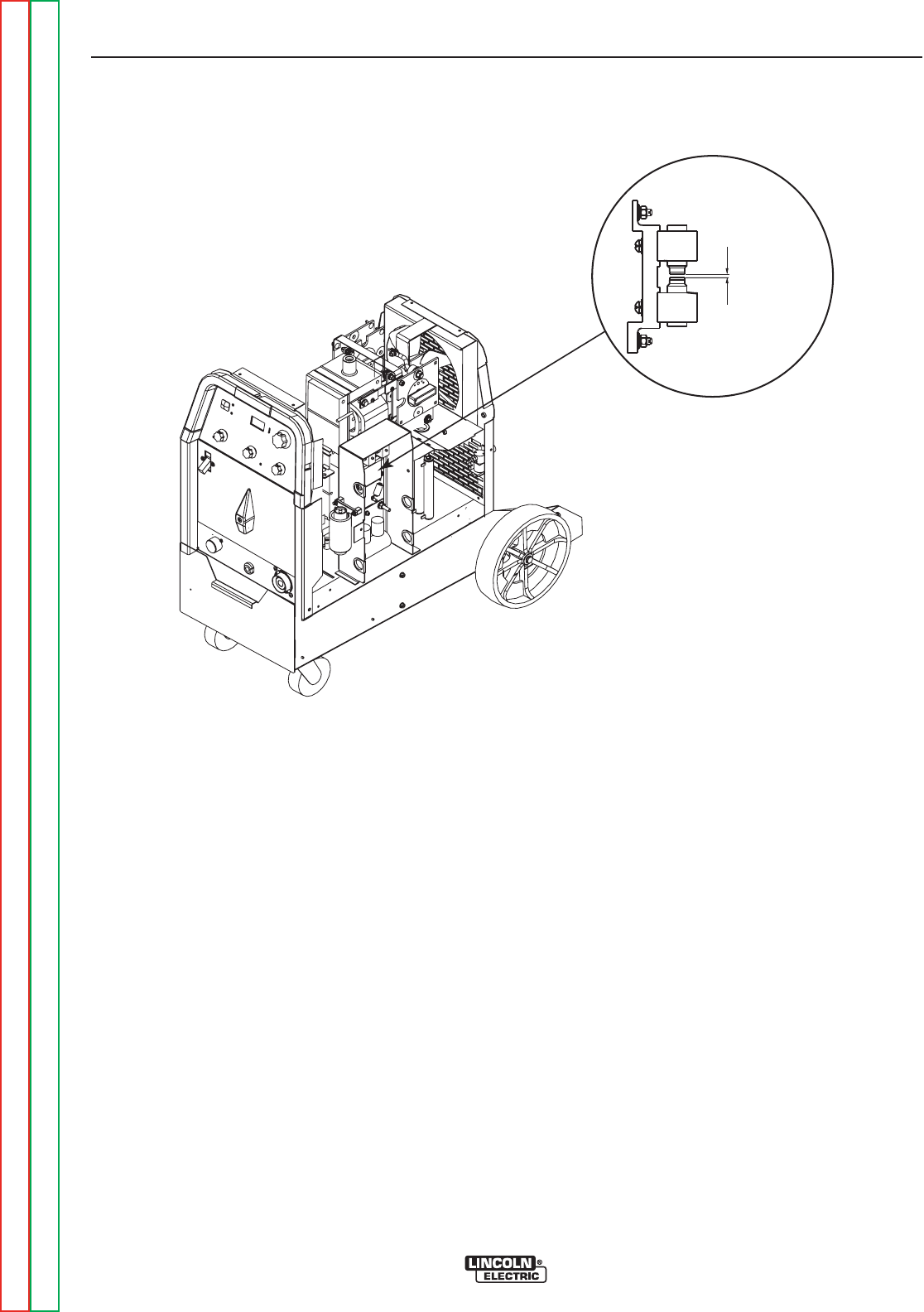

.020 Spark Gap

LEFT SIDE OF MACHINE

FIGURE F.1 – SPARK GAP ASSEMBLY

HIGH FREQUENCY CIRCUIT DISABLE PROCEDURE (continued)

TROUBLESHOOTING AND REPAIR

F-16 F-16

PRECISION TIG® 225

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PROCEDURE

1. Remove input power to the TIG 225 machine.

2. Using the 3/8” nutdriver remove the right side

panel.

3. Locate the Spark Gap Assembly at the right

side of the machine. See Figure F.1.

4. With the 5/64” Allen type wrench loosen the set

screw holding the upper electrode in place.

5. Increase the distance between the electrodes

to at least 3/8” by sliding one electrode away

from the other electrode. Secure the one elec-

trode in this position.

6. This should disable the high frequency circuit.

Visually check to make sure high frequency

sparking is NOT present before connecting

any test equipment to the TIG 225 machine.

7. When voltage testing and scope measurements

are complete reset the spark gap electrodes to

.020” air gap. Tighten the set screw using the

5/64” Allen wrench.