OM-4409 Page 27

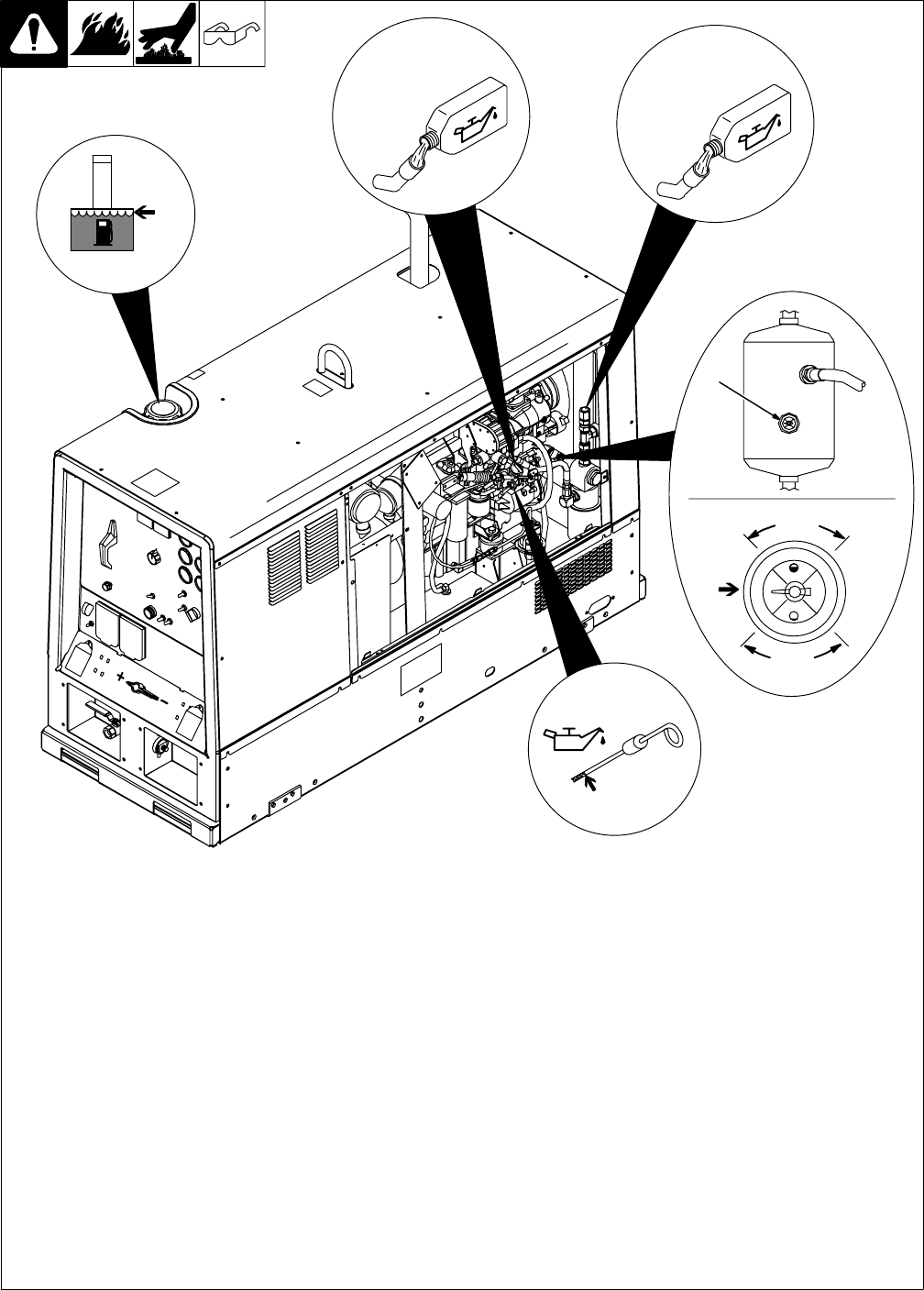

5-7. Engine/Compressor Prestart Checks

. Check all engine/compressor fluids

daily.

Engine must be cold and on a level surface.

Unit is shipped with 20W break-in oil. The

automatic shutdown system stops engine if

oil pressure is too low or coolant tempera-

ture is too high.

. This unit has a low oil pressure shut-

down switch. However, some condi-

tions may cause engine damage before

the engine shuts down. Check oil level

often and do not use the oil pressure

shutdown system to monitor oil level.

Follow run-in procedure in engine manual.

If unburned fuel and oil collect in exhaust

pipe during run-in, see Section 14.

Fuel

NOTICE − Do not use gasoline. Gasoline

will damage engine.

Add fresh diesel fuel before starting to pre-

vent air from entering the fuel system (see

engine maintenance label for fuel specifica-

tions). Leave filler neck empty to allow room

for expansion.

Engine stops if fuel level is low on units with

low fuel shutdown option. Do not run out of

fuel or air may enter fuel system and cause

starting problems. See engine manual to

bleed air from fuel system.

Engine Oil

After fueling, check oil with unit on level sur-

face. If oil is not up to full mark on dipstick,

add oil (see maintenance label for engine oil

specifications).

Compressor Oil

1 Compressor Oil Level Indicator (On

Tank)

Check oil with unit on level surface. Add oil

if oil is not up to full mark on indicator (see

maintenance label for oil specifications).

Cold Weather Starting

. To improve cold weather starting:

Use Starting Aid switch (see Section

6-1).

Keep battery in good condition. Store

battery in warm area.

Use fuel formulated for cold weather

(diesel fuel can gel in cold weather).

Contact local fuel supplier for fuel in-

formation.

Use correct grade oil for cold weather

(see Section 9-1).

Full

803 228

Diesel

Full

Full

1

Too

Low

Too

High

Engine Oil

Compressor

Oil