OM-4409 Page 53

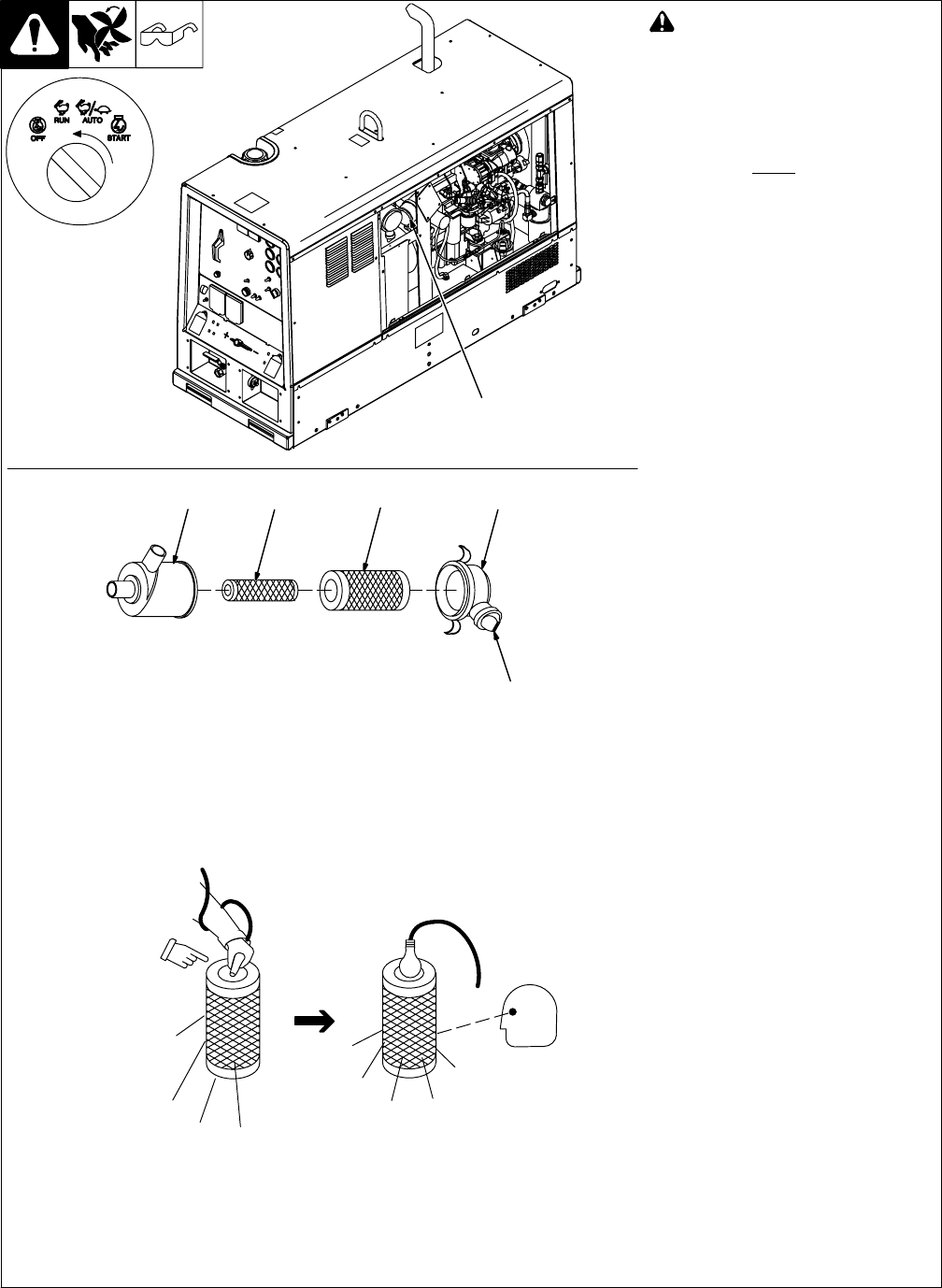

10-3. Servicing Compressor Air Cleaner

aircleaner1 9/02* − 803 228 / 153 929-B / 153 585 / Ref. S-0698-B

! Stop engine.

NOTICE − Do not run air compressor

without air cleaner or with dirty element.

Compressor damage caused by using a

damaged element is not covered by the

warranty.

1 Compressor Air Cleaner

. Remove engine air cleaner cover

and element to access compressor

air cleaner (see Section 9-4)

. The air cleaner primary element can

be cleaned but the dirt holding capac-

ity of the filter is reduced with each

cleaning. The chance of dirt reaching

the clean side of the filter while clean-

ing and the possibility of filter damage

makes cleaning a risk. Consider the

risk of unwarrantable equipment

damage when determining whether

to clean or replace the primary ele-

ment.

If you decide to clean the primary ele-

ment, we strongly recommend instal-

ling an optional safety element to pro-

vide additional air compressor

protection. Never clean a safety ele-

ment. Replace the safety element af-

ter servicing the primary element

three times.

Clean or replace primary element if dirty

(see note above before cleaning). Re-

place primary element if damaged. Re-

place primary element yearly or after six

cleanings.

2 Housing

3 Safety Element

4 Primary Element

5 Cover

6 Dust Ejector

To clean air filter:

Wipe off cover and housing. Remove

cover and dump out dust. Remove ele-

ment(s). Wipe dust from inside cover and

housing with damp cloth. Reinstall safety

element (if present). Reinstall cover.

NOTICE − Do not clean housing with air

hose.

Clean primary element with compressed

air only.

Air pressure must not exceed 100 psi

(690 kPa). Use 1/8 in (3 mm) nozzle and

keep nozzle at least 2 in (51 mm) from

inside of element. Replace primary ele-

ment if it has holes or damaged gaskets.

Reinstall primary element and cover

(dust ejector down).

Blow Inspect

52 4

6

Keep nozzle

2 in (51 mm)

from element.

3

1