OM-4409 Page 48

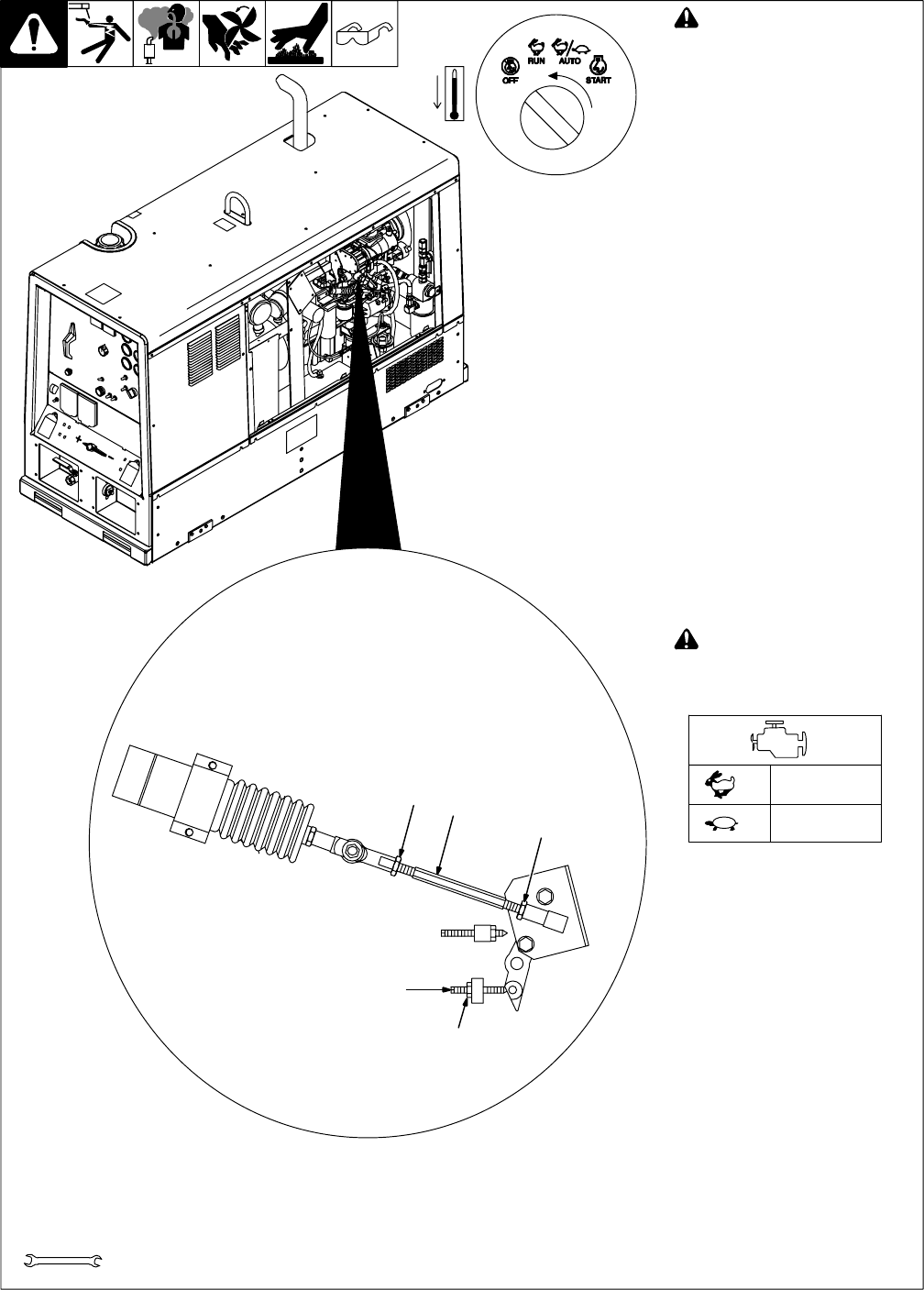

9-6. Adjusting Engine Speed

803 228 / 802 313-A

! Stop engine and let cool.

Engine speed is factory set and

should not require adjustment. Af-

ter tuning engine, check engine no

load speed with a tachometer or fre-

quency meter (see table for no load

speeds). If necessary, adjust speed

as follows:

Start engine and run until warm.

Turn Process/Contactor switch to

Weld Terminals Always On − Stick

position.

1 Throttle Rod

2 Locknut

Loosen locknuts. Place engine

control switch in Run/Idle position.

Wait 15 seconds for throttle sole-

noid to energize and lower engine

speed to idle rpm.

Turn throttle rod to adjust idle

speed. Tighten locknuts.

3 Engine Speed Adjustment

Screw

4 Locknut

Place engine control switch in Run

position.

Loosen locknut. Turn screw to ad-

just weld/power speed. Tighten

locknut.

. Do not set engine speed higher

than specified.

! Stop engine.

Close door.

2

1

3

4

3/8, 7/16 in

1850 rpm Max.

(61.6 Hz)

1235 rpm

(41.1 Hz)

Tools Needed:

2