OM-4409 Page 49

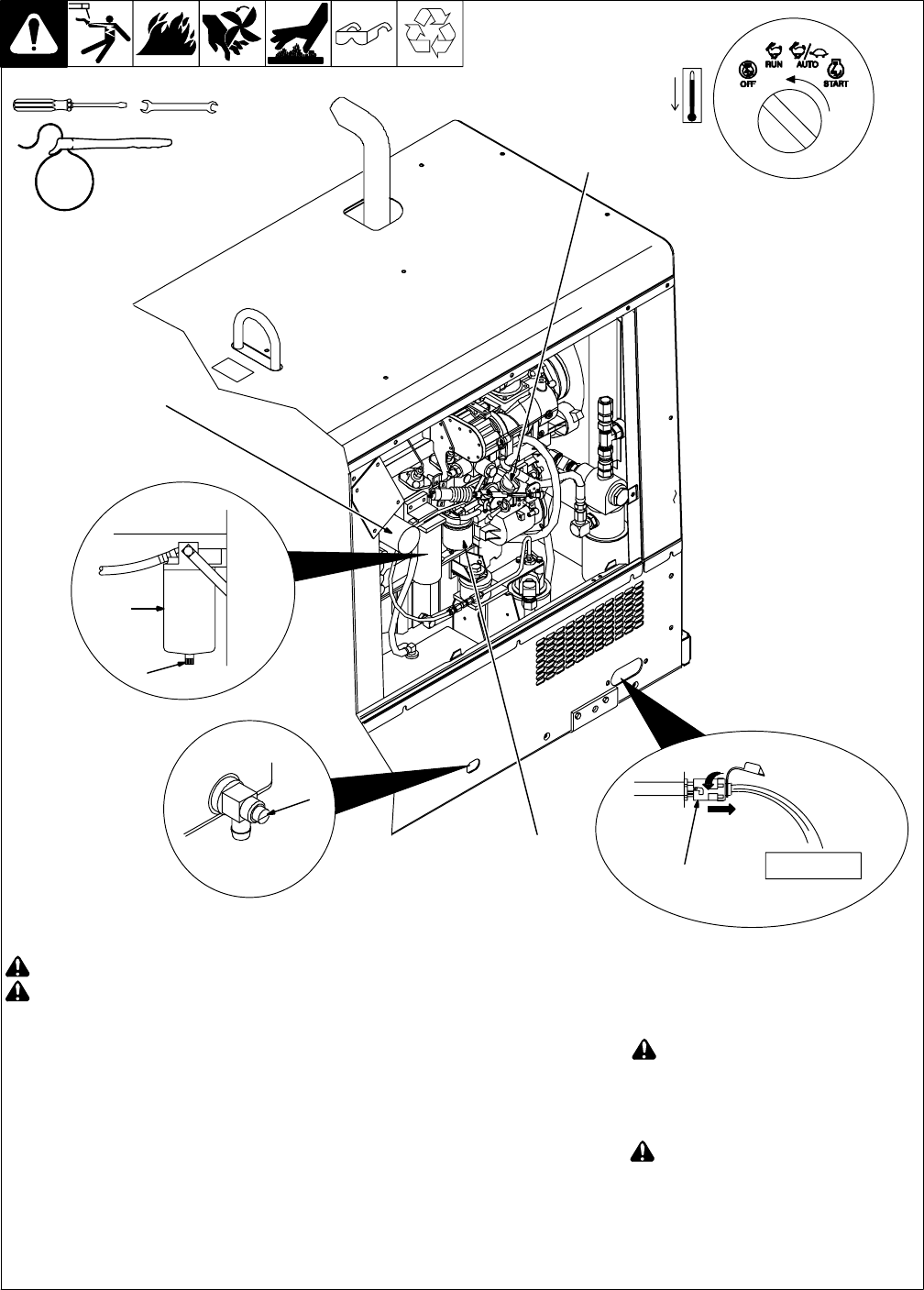

9-7. Servicing Engine Fuel And Lubrication Systems

803 228

! Stop engine and let cool.

! After servicing, start engine and

check for fuel leaks. Stop engine,

tighten connections as necessary,

and wipe up spilled fuel.

1 Oil Filter

2 Oil Drain Hose And Valve

3 Oil Fill Cap

4 Primary Fuel Filter (Fuel/Water

Separator)

5 Petcock

6 Secondary Fuel Filter

7 Fuel Tank Sludge Drain Valve

To change oil and filter:

. The engine oil drain and compressor oil

drain hoses are located together in the

base. Be sure to select the correct hose

when draining engine oil.

Route engine oil drain hose through hole in

base. See engine manual and engine main-

tenance label for oil specifications.

To drain water from fuel system:

Open primary fuel filter petcock and drain

water into metal container. Close petcock

when water-free fuel flows.

To replace primary fuel filter:

Turn filter counterclockwise. Remove filter.

Apply thin coat of fuel to gasket on new filter.

Fill filter with fuel. Install filter and turn clock-

wise until tight. Bleed air from fuel system

according to engine manual.

Inspect fuel lines, and replace if cracked or

worn.

To replace secondary fuel filter:

See engine manual.

Close doors.

To drain sludge from fuel tank:

! Beware of fire. Do not smoke and

keep sparks and flames away from

drained fuel. Dispose of drained fuel

in an environmentally-safe manner.

Do not leave unit unattended while

draining fuel tank.

! Properly lift unit and secure in a level

position. Use adequate blocks or

stands to support unit while drain-

ing fuel tank.

Attach 1/2 ID hose to drain valve. Put metal

container under drain, and use screwdriver

to open sludge drain valve. Close valve

when sludge has drained. Remove hose.

4

5

Tools Needed:

3

7

Right Side

1

6

2