OM-4409 Page 68

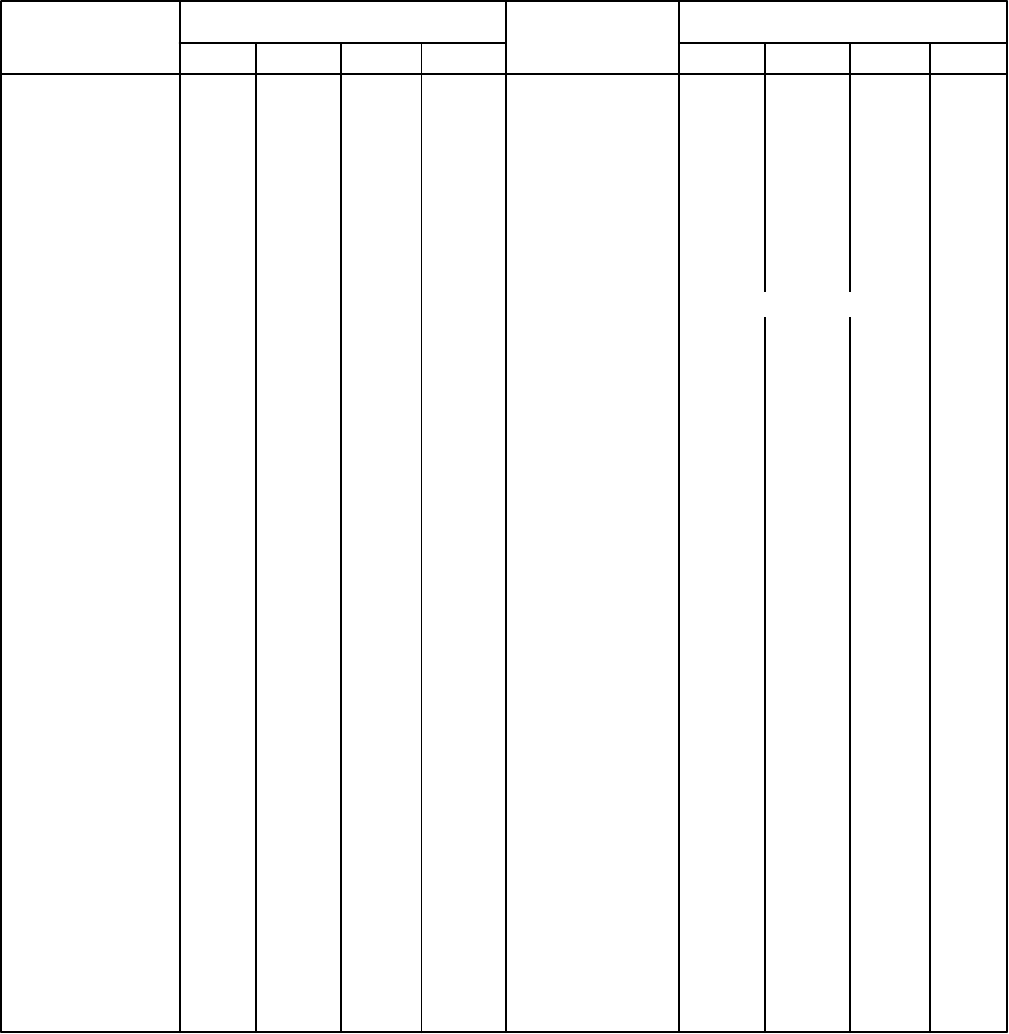

15-2. Approximate Air Consumption (Cubic Feet) To Operate Pneumatic Equipment At

70-90 P.S.I.G.

Drill, 1/18” to 3/8” 3.75 6.25 8.75 25 Burring Tool, Large 3.6 6.0 8.4 24

Drill, 3/8” to 5/16” 5.25 8.75 12.25 35 Rammers, Small 3.9 3.25 9.1 13

Screwdriver,

#2 to #6 Screw 1.8 3.0 4.2 12 Rammers, Medium 5.1 8.5 11.9 34

Screwdriver,

#6 to 5/16” Screw 3.6 6.0 8.4 24 Rammers, Large 6.0 10.0 14.0 40

Tapper, to 3/8” 3.0 5.0 7.0 20 Backfill Tamper 3.75 6.25 8.75 25

Nutsetters, to 3/8” 3.6 6.0 8.4 24 Compression Riveter 0.2 cu. ft. per cycle

Nutsetters, to 3/4” 4.5 7.5 10.5 30 Air Motor,

1 Horsepower 3.75 6.3 8.75 25

Impact Wrench, 1/4” 2.25 3.75 5.3 15 Air Motor,

2 Horsepower 7.5 12.5 17.5 50

Impact Wrench, 3/8” 3.0 5.0 7.0 20 Air Motor,

3 Horsepower 11.25 18.75 26.3 75

Impact Wrench, 5/8” 4.5 7.5 10.5 30

Paint Spray Gun

Impact Wrench, 3/4” 5.25 8.75 12.25 35 (Production) 3.0 5.00 7.00 20

Impact Wrench, 1” 6.75 11.25 15.75 45 ,HAMMERS

Impact Wrench, 1-1/4” 8.25 13.75 19.2 55 Scaling Hammer 1.3 3.0 4.2 12

Die Grinder, Small 2.25 3.75 5.3 15 Chipping Hammer 4.5 7.5 10.5 30

Die Grinder, Medium 3.6 6.0 8.4 24

Riveting Hammer,

Horizontal Grinder, 2” 3.0 5.0 7.0 20 Light 2.25 3.75 5.25 15

Horizontal Grinder, 4” 9.0 15.0 21.0 60 Riveting Hammer,

Heavy 4.5 7.5 10.5 30

Horizontal Grinder, 6” 9.0 15.0 21.0 60

SAWS

Circular, 8” 6.75 11.25 15.75 45

Horizontal Grinder, 8” 12.0 20.0 28.0 80

Circular, 12” 9.75 16.25 23.8 65

Vertical Grinders and

Sanders, 5” Pad 5.25 8.75 12.25 35 Chain, Lightweight 4.20 7.0 9.8 28

Vertical Grinders and

Sanders, 7” Pad 9.0 15.0 21.0 60 Chain, Heavy Duty 13.1 21.8 30.5 87

Vertical Grinders and

Sanders, 9” Pad 10.5 17.5 24.5 70

Burring Toll, Small 2.25 3.75 5.3 15

MISCELLANEOUS

PORTABLE

TOOLS

Percent Use Factor And

Compressed Air Consumption (CF)

MISCELLANEOUS

PORTABLE

TOOLS

Percent Use Factor And

Compressed Air Consumption (CF)

9 sec 15 sec 21 sec 1 min9 sec 15 sec 21 sec 1 min

Always check with tool manufacturers for actual air consumption of tools being used. The above is based on averages and should not be

considered accurate for any particular make of tool.

Above tools are rated based upon typical “on-load” performance characteristics.

For other values, adjust the C.F. air consumption on a proportional basis.

The cubic feet (C.F.) air consumption for 1 minute may also be expressed as air consumption in cubic feet per minute (C.F.M.)