OM-4409 Page 55

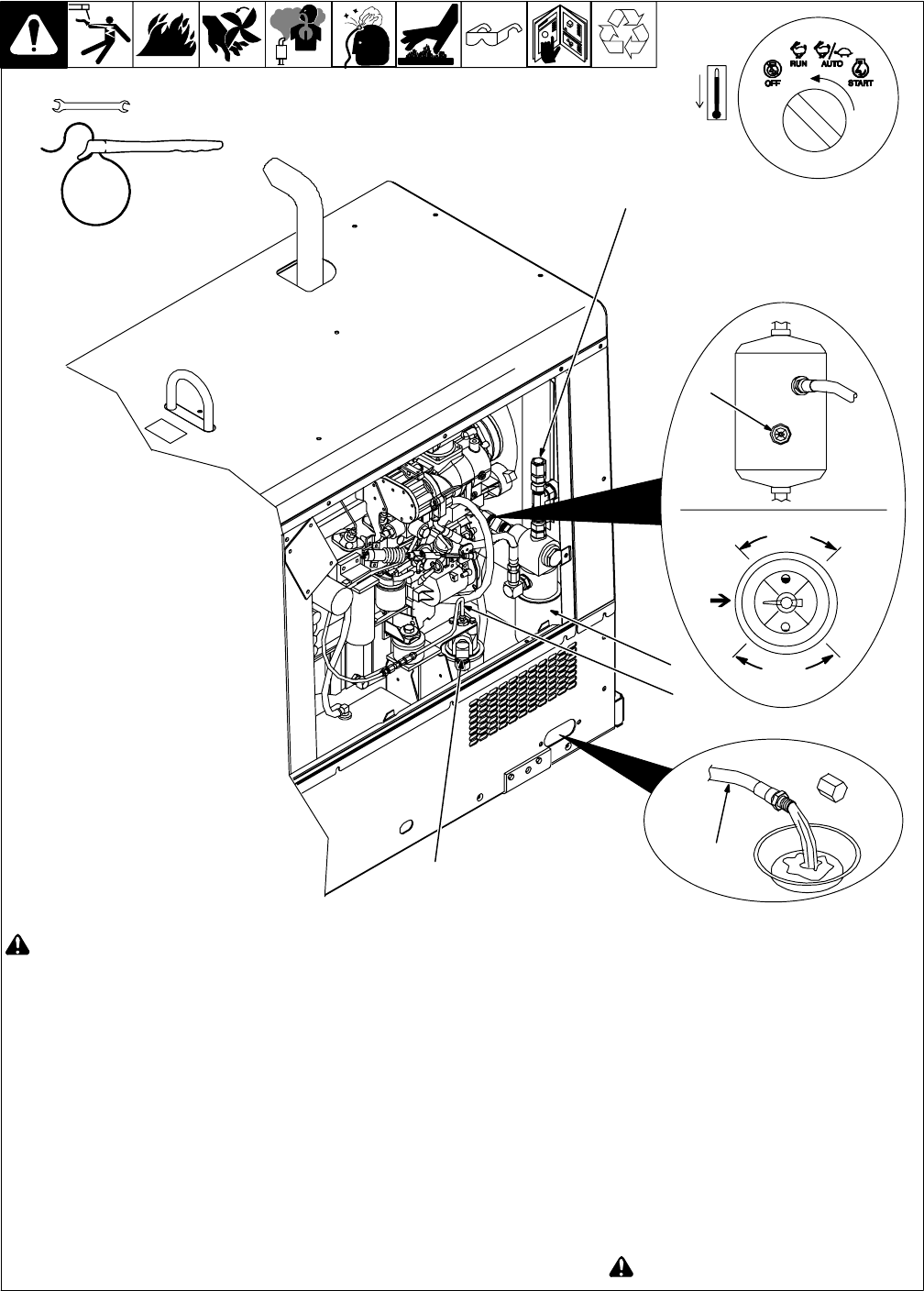

10-5. Servicing Air Compressor

803 228

! Stop engine and let cool. Wait 20 sec-

onds for system pressure to drop be-

fore changing oil.

1 Air Compressor Oil Filter

2 Air Compressor Air/Oil Separator

3 Air Compressor Oil Drain Hose

w/Removable Cap

4 Air Compressor Oil Fill Cap

5 Air Compressor Oil Level Indicator (On

Tank)

6 Oil Scavenge Tube

To change compressor oil and filter:

. The engine oil drain and compressor oil

drain hoses are located together in the

base. Be sure to select the correct hose

when draining compressor oil.

. Be sure o-rings at oil drain and oil fill fit-

tings are in place before reinstalling caps.

Drain compressor oil while compressor is still

warm.

Route compressor oil drain hose through hole

in base. Remove compressor oil fill cap. Re-

move cap from oil drain hose and drain oil into

a suitable container. Reinstall oil drain hose

cap. Tighten cap with wrench.

Remove filter by turning filter counterclock-

wise. Remove filter. Apply thin coat of oil to

gasket on new filter. Install new filter and turn

clockwise until tight.

Add recommended oil until oil level indicator

shows system is full (see compressor mainte-

nance label for oil specifications). Reinstall oil

fill cap. Tighten cap with wrench.

To replace air/oil separator:

Loosen nut securing tube on separator base.

Lift oil scavenge tube from separator. Turn fil-

ter counterclockwise. Remove filter.

Apply thin coat of oil to gasket on new filter.

Install filter and turn clockwise. Reinstall oil

scavenge tube.

Start engine, run air compressor, and check

for oil leaks.

! Stop engine.

Tools Needed:

2

1

4

Right Side

6

7/8, 15/16 in

3

Full

5

Too

Low

Too

High