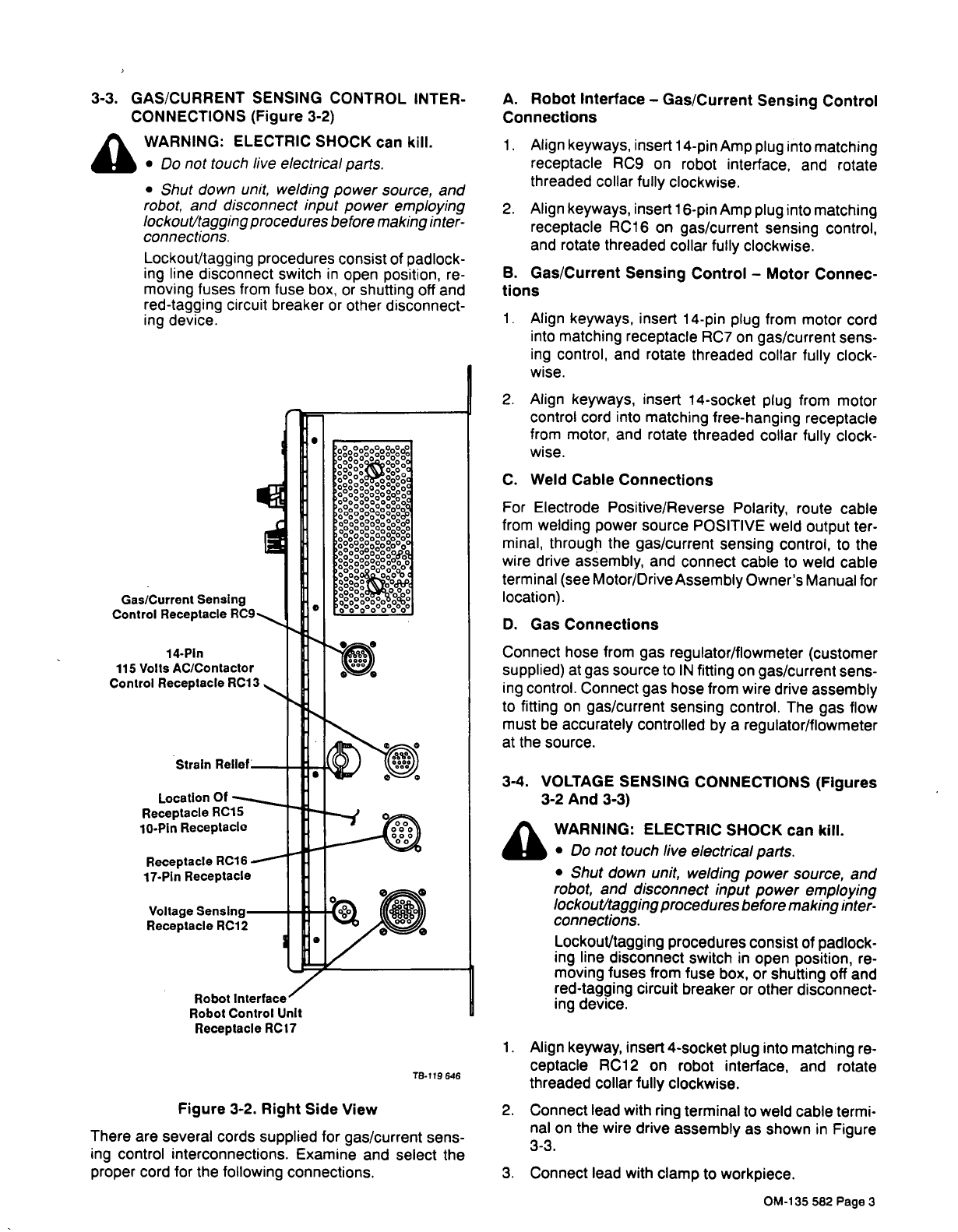

3-3.

GAS/CURRENT

SENSING

CONTROL

INTER

CONNECTIONS

(Figure

3-2)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shut

down

unit,

welding

power

source,

and

robot,

and

disconnect

input

power

employing

lockout/tagging

procedures

before

making

inter

connections.

Lockout/tagging

procedures

consist

of

padlock

ing

line

disconnect

switch

in

open

position,

re

moving

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

disconnect

ing

device.

A.

Robot

Interface

Gas/Current

Sensing

Control

Connections

1.

Align

keyways,

insert

14-pin

Amp

plug

into

matching

receptacle

RC9

on

robot

interface,

and

rotate

threaded

collar

fully

clockwise.

2.

Align

keyways,

insert

16-pin

Amp

plug

into

matching

receptacle

RC16

on

gas/current

sensing

control,

and

rotate

threaded

collar

fully

clockwise.

B.

Gas/Current

Sensing

Control

Motor

Connec

tions

1.

Align

keyways,

insert

14-pin

plug

from

motor

cord

into

matching

receptacle

RC7

on

gas/current

sens

ing

control,

and

rotate

threaded

collar

fully

clock

wise.

2.

Align

keyways,

insert

14-socket

plug

from

motor

control

cord

into

matching

free-hanging

receptacle

from

motor,

and

rotate

threaded

collar

fully

clock

wise.

C.

Weld

Cable

Connections

For

Electrode

Positive/Reverse

Polarity,

route

cable

from

welding

power

source

POSITIVE

weld

output

ter

minal,

through

the

gas/current

sensing

control,

to

the

wire

drive

assembly,

and

connect

cable

to

weld

cable

terminal

(see

Motor/Drive

Assembly

Owners

Manual

for

location).

D.

Gas

Connections

Connect

hose

from

gas

regulator/flowmeter

(customer

supplied)

at

gas

source

to

IN

fitting

on

gas/current

sens

ing

control.

Connect

gas

hose

from

wire

drive

assembly

to

fitting

on

gas/current

sensing

control.

The

gas

flow

must

be

accurately

controlled

by

a

regulator/flowmeter

at

the

source.

3-4.

VOLTAGE

SENSING

CONNECTIONS

(Figures

3-2

And

3-3)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shut

down

unit,

welding

power

source,

and

robot,

and

disconnect

input

power

employing

lockout/tagging

procedures

before

making

inter

connections.

Lockout/tagging

procedures

consist

of

padlock

ing

line

disconnect

switch

in

open

position,

re

moving

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

disconnect

ing

device.

Figure

3-2.

Right

Side

View

TG-tt9

646

There

are

several

cords

supplied

for

gas/current

sens

ing

control

interconnections.

Examine

and

select

the

proper

cord

for

the

following

connections.

1.

Align

keyway,

insert

4-socket

plug

into

matching

re

ceptacle

RC12

on

robot

interface,

and

rotate

threaded

collar

fully

clockwise.

2.

Connect

lead

with

ring

terminal

to

weld

cable

termi

nal

on

the

wire

drive

assembly

as

shown

in

Figure

3-3.

3.

Connect

lead

with

clamp

to

workpiece.

Gas/Current

SensIng

Control

Receptacle

RC9

14-PIn

115

Volts

AC/Contactor

Control

Receptacle

RC13

OM-135

582

Page

3