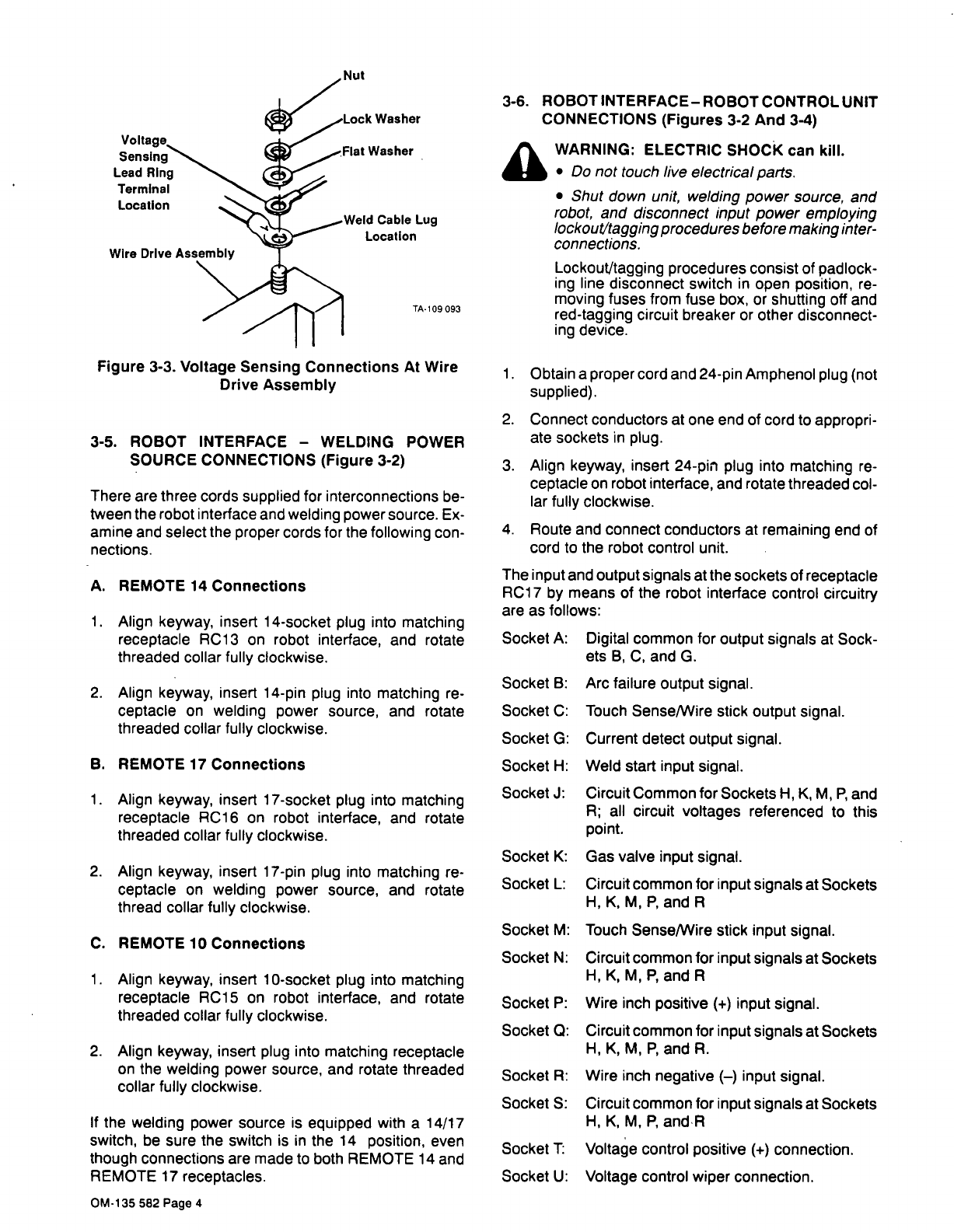

Figure

3-3.

Voltage

Sensing

Connections

At

Wire

Drive

Assembly

3-5.

ROBOT

INTERFACE

WELDING

POWER

SOURCE

CONNECTIONS

(Figure

3-2)

There

are

three

cords

supplied

for

interconnections

be

tween

the

robot

interface

and

welding

power

source.

Ex

amine and

select

the

proper

cords

for

the

following

con

nections.

A.

REMOTE

14

Connections

1.

Align

keyway,

insert

14-socket

plug

into

matching

receptacle

RC13

on

robot

interface,

and

rotate

threaded

collar

fully

clockwise.

2.

Align

keyway,

insert

14-pin

plug

into

matching

re

ceptacle

on

welding

power

source,

and

rotate

threaded

collar

fully

clockwise.

B.

REMOTE

17

Connections

1.

Align

keyway,

insert

17-socket

plug

into

matching

receptacle

RC16

on

robot

interface,

and

rotate

threaded

collar

fully

clockwise.

2.

Align

keyway,

insert

17-pin

plug

into

matching

re

ceptacle

on

welding

power

source,

and

rotate

thread

collar

fully

clockwise.

C.

REMOTE

10

Connections

1.

Align

keyway,

insert

10-socket

plug

into

matching

receptacle

RC15

on

robot

interface,

and

rotate

threaded

collar

fully

clockwise.

2.

Align

keyway,

insert

plug

into

matching

receptacle

on

the

welding

power

source,

and

rotate

threaded

collar

fully

clockwise.

If

the

welding

power

source

is

equipped

with

a

14/17

switch,

be

sure

the

switch

is

in

the

14

position,

even

though

connections

are

made

to

both

REMOTE

14

and

REMOTE

17

receptacles.

3-6.

ROBOTINTERFACE-ROBOTCONTROLUNIT

CONNECTIONS

(Figures

3-2

And

3-4)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shut

down

unit,

welding

power

source,

and

robot,

and

disconnect

input

power

employing

lockout/tagging

procedures

before

making

inter

connections.

Lockout/tagging

procedures

consist

of

padlock

ing

line

disconnect

switch

in

open

position,

re

moving

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

disconnect

ing

device.

1.

Obtain

a

proper

cord

and

24-pin

Amphenol

plug

(not

supplied).

2.

Connect

conductors

at

one

end

of

cord

to

appropri.

ate

sockets

in

plug.

3.

Align

keyway,

insert

24-pin

plug

into

matching

re

ceptacle

on

robot

interface,

and

rotate

threaded

col

lar

fully

clockwise.

4.

Route

and

connect

conductors

at

remaining

end

of

cord

to

the

robot

control

unit.

The

input

and

output

signals

at

the

sockets

of

receptacle

RC17

by

means

of

the

robot

interface

control

circuitry

are

as

follows:

Socket

A:

Digital

common

for

output

signals

at

Sock

ets

B,

C,

and

G.

Arc

failure

output

signal.

Touch

Sense/Wire

stick

output

signal.

Socket

G:

Current

detect

output

signal.

Socket

H:

Weld

start

input

signal.

Socket

J:

Circuit

Common

for

Sockets

H,

K,

M,

P,

and

A;

all

circuit

voltages

referenced

to

this

point.

Socket

K:

Gas

valve

input

signal.

Socket

L:

Circuit

common

for

input

signals

at

Sockets

H,

K,

M,

P,

and

R

Socket

M:

Touch

Sense/Wire

stick

input

signal.

Socket

N:

Circuit

common

for

input

signals

at

Sockets

H,

K,

M,

P~

and

A

Socket

P:

Wire

inch

positive

(+)

input

signal.

Socket

0:

Circuit

common

for

input

signals

at

Sockets

H,

K,

M,

P,

and

R.

Socket

R:

Wire

inch

negative

()

input

signal.

Socket

S:

Circuit

common

for

input

signals

at

Sockets

H,

K,

M,

P,

andR

Voltage

control

positive

(+)

connection.

Voltage

control

wiper

connection.

Nut

Sensing

Lead

Ring

Terminal

Location

Cable

Lug

Location

TA-109

093

Socket

B:

Socket

C:

Socket

T:

Socket

U:

OM.135

582

Page

4