A.

Installation

Of

Spool-Type

Wire

(Figure 4-1)

4-7.

WELDING

WIRE

THREADING

1.

Remove

retaining

ring

from

hub.

2.

Slide

wire

spool

on

hub

so

that

wire

feeds

off

the

bottom

of

the

spool.

3.

Rotate

wire

spool

until

hole

in spool

slides

over

pin

in

hub and

seats

against back

flange

of

the

hub.

4.

Insert optional

compression spring

if

required.

5.

Reinstall retaining

ring

to

secure

wire

spool

on

hub.

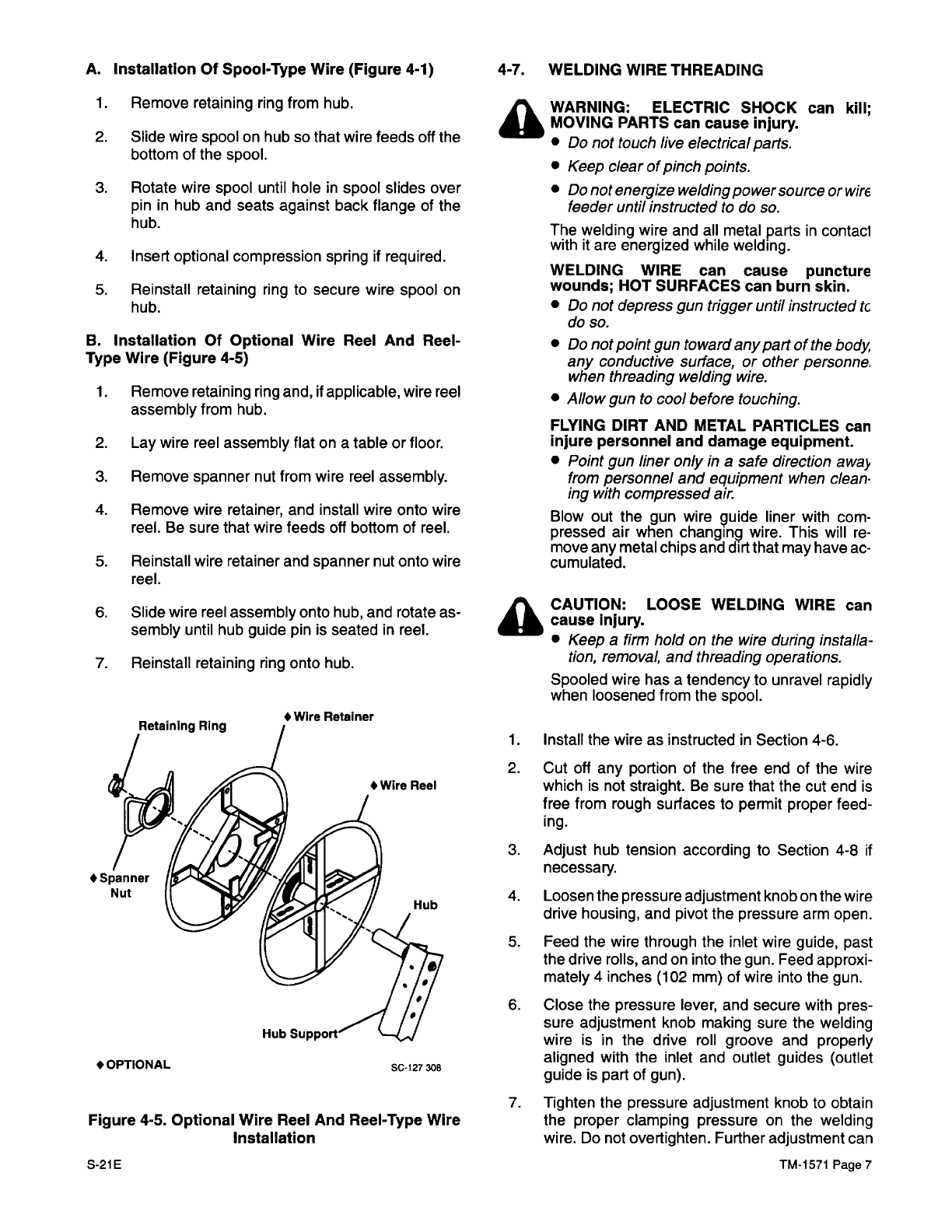

B.

Installation

Of

Optional

Wire

Reel

And

Reel-

Type

Wire

(Figure 4-5)

1.

Remove

retaining

ring

and,

if

applicable,

wire

reel

assembly

from hub.

2.

Lay

wire

reel

assembly

flat

on a

table

or

floor.

3.

Remove

spanner

nut

from

wire

reel

assembly.

4.

Remove wire

retainer,

and

install

wire onto wire

reel.

Be

sure

that

wire

feeds

off

bottom

of

reel.

5.

Reinstall

wire

retainer and

spanner

nut

onto wire

reel.

6.

Slide

wire

reel

assembly

onto

hub,

and

rotate

as

-

sembly

until

hub

guide

pin is

seated in

reel.

7.

Reinstall retaining

ring

onto

hub.

•

Spanner

Nut

•

OPTIONAL

Figure

4-5.

Optional Wire

Reel

And

Reel-Type

Wire

Installation

A

A

WARNING:

ELECTRIC

SHOCK

can

kill;

MOVING

PARTS

can

cause

injury.

•

Do

not

touch

live

electrical

parts.

•

Keep

clear

of

pinch

points.

•

Do

not

energize welding

power

source

or

wirE

feeder

until

instructed

to

do

so.

The welding

wire

and

all

metal

parts

in

contaci

with

it

are

energized

while

welding.

WELDING

WIRE can

cause puncture

Wounds;

HOT

SURFACES

can

burn skin.

•

Do

not

depress

gun

trigger

untll

instructed

tc

do

so.

•

Do

not

point

gun towa

rd

any

part of

the

body

any

conductive

surface,

or

other

personne.

when threading

welding

wire.

•

Allow

gun

to

cool before

touching.

FLYING

DIRT

AND

METAL PARTICLES can

injure personnel

and

damage equipment.

•

Point

gun

liner only

in

a

safe direction

awaj~

from

personnel

and

equipment when

clean~

ing with

compressed

air.

Blow

out the

gun

wire

9uide

liner

with

com

-

pressed

air

when

changing

wire.

This

will

re

-

move

any

metal

chips

and

dirt

that

may

have

ac

-

cumulated.

CAUTION:

LOOSE

WELDING

WIRE

can

cause

Injury.

•

Keep

a

firm

hold

on

the wire

during

installa

-

tion,

removal,

and

threading

operations.

Spooled wire

has

a

tendency

to

unravel

rapidly

when

loosened

from

the

spool.

1.Install

the

wire

as

instructed

in

Section 4-6.

2.

Cut

off

any

portion

of

the

free

end

of

the

wire

which

is

not straight.

Be

sure

that

the

cut

end

is

free

from

rough

surfaces

to

permit

proper

feed

-

ing.

3.

Adjust

hub

tension according to Section

4-8

if

necessary.

4.

Loosen

the

pressure

adjustment knob

on

the

wire

drive

housing,

and

pivot

the

pressure

arm open.

5.

Feed

the

wire

through

the

inlet

wire

guide, past

the

drive

rolls,

and

on

into

the

gun.

Feed

approxi

-

mately

4

inches

(102

mm)

of

wire

into

the

gun.

6.

Close

the

pressure

lever,

and

secure

with

pres

-

sure

adjustment knob

making

sure

the

welding

wire

is

in

the

drive

roll

groove

and

properly

aligned with

the

inlet

and

outlet

guides

(outlet

guide

is

part of

gun).

7.

Tighten

the

pressure

adjustment knob

to

obtain

the

proper

clamping

pressure

on

the

welding

wire.

Do

not

overtighten. Further

adjustment

can

•Wlre

Retainer

SC-127

306

S-21E

TM-1571

Page

7