SECTION

8—

TROUBLESHOOTING

A

8-1.

TESTING

INSTRUMENTS

AND

INFORMA

-

TION

The

service procedures

in

this

manual

require

proper

testing

instruments.

Use

a

good quality

digital

volt-

ohmmeter

(DVM)

with

one

megohm

input

impedance

or

greater

and

diode

check capability

(use

an

analog VOM

for

variable

resistor

testing). If

an

oscilloscope

is

speci

-

fied,

use

a

good

quality

unit

with

one

megohm

input

im

-

pedance

or

greater.

If a

circuit

board

has

a protective

coating,

it

will

be

necessary

to remove

coating

or

use

needle probes

in

the

test

area

to

obtain

proper

contact.

Recoat

areas

if

necessary

to retain

corrosion

protection.

Digital

volt-ohmmeters

(DVM’s)

do

not

require

lead

po

-

larity attention

when making connections.

However,

the

meter

may

indicate

a

—

(negative)

voltage

when

the

test

procedure specified

a

+

(positive) voltage.

If

the

incor

-

rect

polarity

appears

on

the

display, reverse

meter

lead

connections

to

test

points.

8-2.

CIRCUIT

BOARD

HANDLING

PRECAUTIONS

WARNING:

ELECTRIC

SHOCK

can

kill.

•

Do

not

touch live

electrical

parts.

•

Shut

down

wire

feeder

and

welding

power

source,

and

disconnect

input

power

employ

-

ing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging procedures

forwirefeedercon

-

sist

of

disconnecting

interconnecting

cord,

and

for

welding

power

source

consist

of

padlocking

line

disconnect switch

in

open

position,

remov

-

ing

fuses

from

fuse box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

Stop

engine,

and

disconnect

negative

(—)

battery

cable

from

battery

on

welding

gen

-

erators.

MOVING

PARTS

can

cause serious

injury.

•

Keep

away

from

moving

parts.

HOT

SURFACES

can

cause

severe burns.

•

Allow

cooling

period

before servicing.

CAUTION:

ELECTROSTATIC

DISCHARGE

(ESD)

can

damage

circuit

boards.

•

Put

on

properly

grounded

wrist

strap

BEFORE

handling

circuit

boards.

•

Transport

circuit

boards

in

proper

static-

shielding

carriers

or

packages.

•

Perform

work

only

at

a static-safe

work

area.

INCORRECT

INSTALLATION

or

misaligned

plugs

can

damage

circuit board.

•

Be

sure

that

plugs

are

properly

installed

and

aligned.

EXCESSIVE

PRESSURE

can

break

circuit

board.

•

Use

only

minimal pressure and

gentle

move

-

ment

when

disconnecting

or

connecting

board

plugs

and

removing

or

installing

board.

A

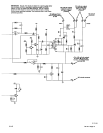

8-3.

TROUBLESHOOTING

(Table

8-1

And

Dia

-

gram

8-1)

A

WARNING:

ELECTRIC

SHOCK

can

kill.

•

Do

not

touch

live

electrical

parts.

•

Shut

down

wire

feeder

and

welding

power

source,

and

disconnect

input

power

employ

-

ing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging procedures

forwire

feeder

con-

sist

of

disconnecting

interconnecting

cord,

and

for

welding

power source consist

of

padlocking

line

disconnect

switch

in

open

position,

remov

-

ing

fuses

from

fuse box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

Stop

engine,

and

disconnect negative

(—)

battery

cable

from

battery

on

welding

gen

-

erators.

MOVING

PARTS

can

cause

serious

injury.

•

Keep away

from

moving

parts.

HOT

SURFACES

can

cause

severe

burns.

•

Allow

cooling

period

before servicing.

Troubleshooting

to

be

performed

only

by

qualified

persons.

The

troubleshooting

table

is

designed

to

diagnose some

of

the

troubles

that

can

develop

in

this

wire

feeder.

Any

circuit

normally

tied

to

ground must

be

at

ground

poten

-

tial.

Use

the table

in

conjunction

with the

diagrams

in

this

manual

and

the exploded

views

and

component

values

in

the

Service

Parts Manual

while performing

tro

-

ubleshooting

procedures.

When replacing

components,

use

only

genuine

MILLER

replacement

parts.

MILLER parts

are

required

for

war-

ranty

repair by

authorized

warranty

service

agency.

Resistance

and

continuity

measurements

must

be

made

with the

unit

shut

down.

Isolate

components

be-

fore

making

resistance

and

continuity

measurements.

IMPORTANT:

Before beginning troubleshooting

proce

-

dures,

visually

examine

internalcomponents

for

signs

of

overheating

and

failure.

Many

major problems,

such

as

winding(s) failure

are

usually

apparent

by

discoloration,

smoke,

and

smell.

Fortunately

most

elect

rical

pro

blems

are

relatively

simple:

blown

fuses,

tripped

circuit

break

-

ers,

incorrect

switch positions, loose

connections,

cor

-

rosion,

and

the

like.

A

complete,

careful

inspection

often

saves

considerable

time,

money

and

frustration.

IMPORTANT: Be

sure

that

all connections

are

correct

and

secure according

to Section

4

and

that

all

controls

and

switches

are

in

proper

positions

before

proceeding

with

troubleshooting.

TM-1571 Page

14

S-21E