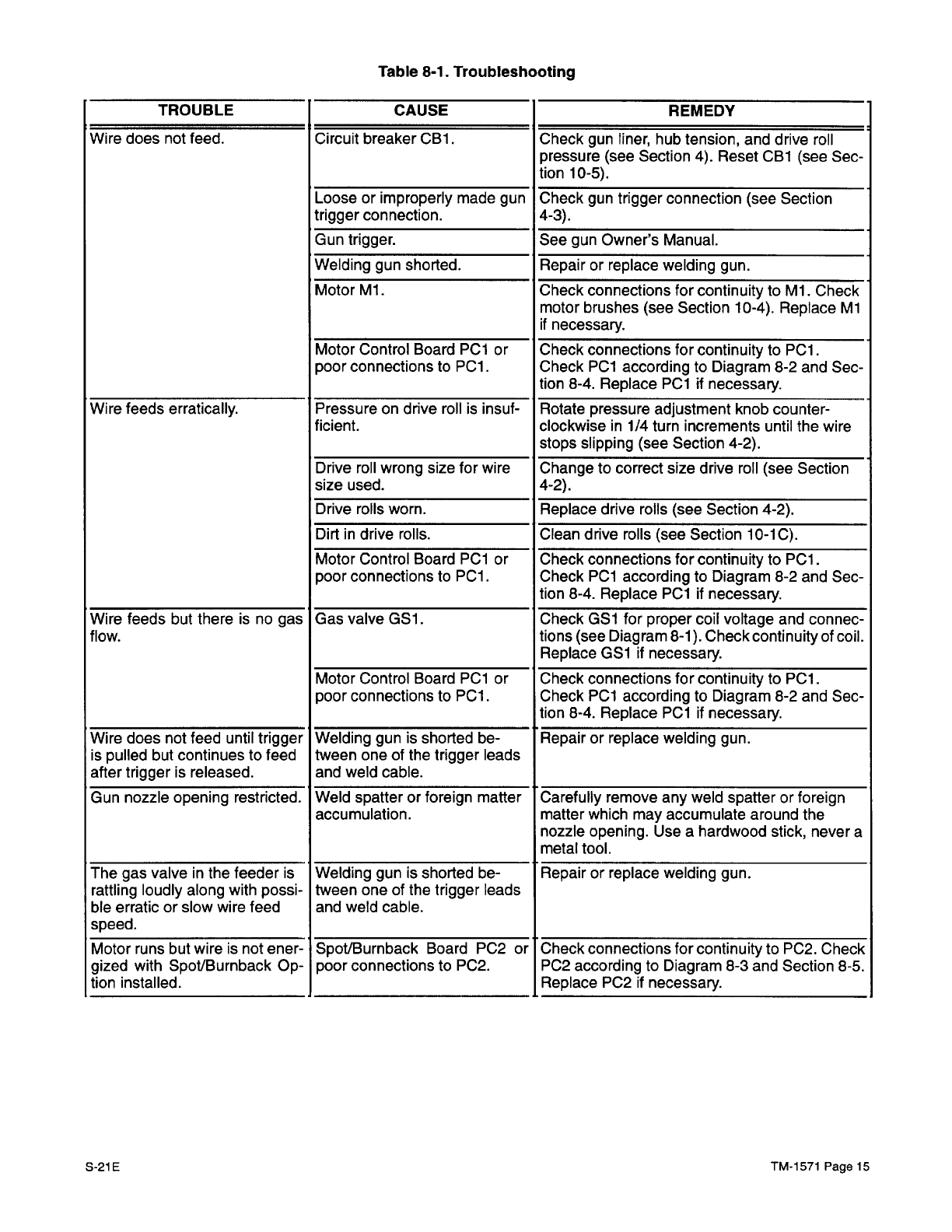

Table 8-1.

Troubleshooting

TROUBLE

CAUSE REMEDY

Wire

does not feed.

Circuit

breaker

CB1.

Check

gun

liner,

hub

tension,

and

drive

roll

pressure

(see

Section

4).

Reset

CBl

(see

Sec

tion

10-5).

Loose

or

improperly

made gun

trigger

connection.

Check

gun

trigger

connection

(see

Section

4-3).

Gun

trigger. See

gun

Owner’s

Manual.

Welding

gun

shorted.

Repair

or

replace

welding

gun.

Motor

Ml.

Check

connections

for

continuity

to

Ml.

Check

motor brushes

(see

Section

10-4).

Replace

Ml

if

necessary.

Motor

Control

Board

PCi

or

poor connections

to

PCl.

Check

connections

for

continuity

to

PCl.

Check

PCi

according

to

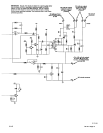

Diagram

8-2

and

Sec

tion

8-4.

Replace

PCl

if

necessary.

Wire feeds

erratically. Pressure

on

drive

roll

is

insuf-

ficient.

Rotate

pressure adjustment

knob

counter

clockwise

in

1/4

turn

increments

until

the

wire

stops

slipping

(see

Section

4-2).

Drive

roll

wrong size

for wire

size

used.

Change

to

correct

size drive

roll

(see

Section

4-2).

Drive rolls

worn.

Replace

drive rolls

(see

Section

4-2).

Dirt in

drive

rolls.

Clean drive rolls

(see

Section

l0-lC).

Motor

Control

Board

PCl

or

poor

connections

to

PCi.

Check

connections

for

continuity

to

PCi.

Check

PCi

according

to

Diagram 8-2

and

Sec

tion

8-4.

Replace

PCi

if

necessary.

Wire feeds

but there

is

no

gas

flow.

Gas valve

GSl.

Check

GS1

for

proper

coil

voltage

and

connec

tions

(see

Diagram

8-1).

Check

continuity

of

coil.

Replace

GSl

if

necessary.

Motor

Control

Board

PCl

or

poor

connections

to

PCl.

Check

connections

for

continuity

to

PCl.

Check

PCl

according

to

Diagram

8-2

and

Sec

tion

8-4.

Replace

PCl

if

necessary.

Wire

does not

feed

until

trigger

is

pulled

but

continues

to

feed

after

trigger

is

released.

Welding

gun

is

shorted

be-

tween

one of

the

trigger leads

and

weld

cable.

Repair

or

replace

welding

gun.

Gun nozzle

opening

restricted. Weld

spatter

or

foreign

matter

accumulation.

Carefully

remove

any

weld spatter

or

foreign

matter

which

may accumulate

around the

nozzle

opening.

Use

a hardwood

stick,

never

a

metal

tool.

The

gas

valve

in

the

feeder

is

rattling

loudly

along

with possi-

ble

erratic

or

slow

wire

feed

speed.

Welding

gun

is

shorted

be-

tween

one of

the

trigger leads

and

weld

cable.

Repair

or

replace

welding

gun.

Motor

runs

but

wire

is

not

ener-

gized

with

Spot/Burnback

Op-

tion

installed.

Spot/Burnback

Board PC2

or

poor connections

to

PC2.

Check

connections

for

continuity

to

PC2.

Check

PC2

according

to Diagram

8-3

and Section 8-5.

Replace

PC2

if

necessary.

TM-i

571

Page

15

5-21E