SECTION

5-

OPERATOR

CONTROLS

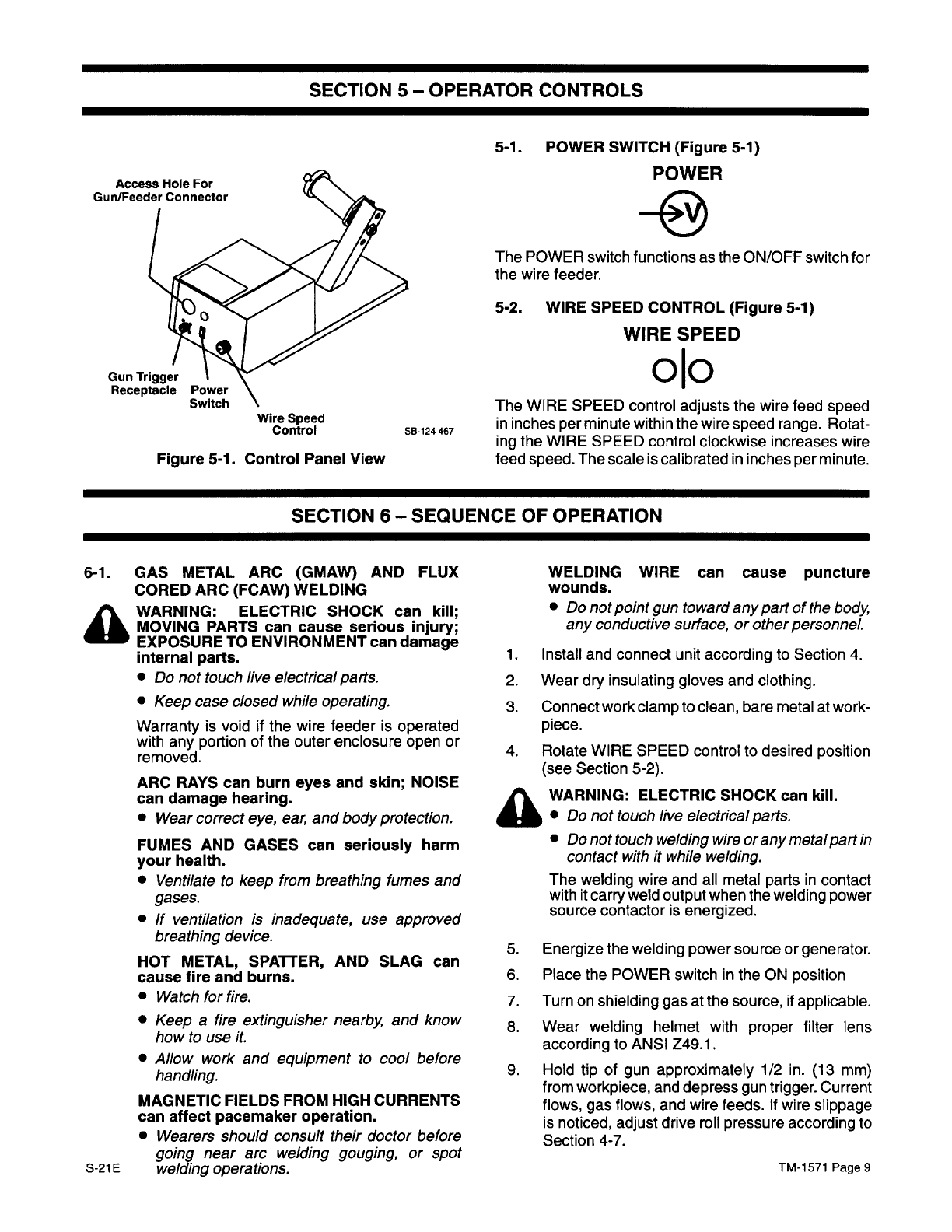

5-1.

POWER

SWITCH

(Figure 5-1)

POWER

The

POWER switch

functions as

the

ON/OFF switch

for

the

wire

feeder.

5-2. WIRE SPEED

CONTROL

(Figure 5-1)

WIRE SPEED

ojo

The

WIRE

SPEED

control

adjusts

the

wire

feed

speed

88-124

467

in

inches per

minute

within

the

wire

speed

range.

Rotat

-

ing

the WIRE

SPEED

control

clockwise

increases

wire

feed

speed.

The

scale

is

calibrated

in

inches per

minute.

SECTION

6—

SEQUENCE

OF

OPERATION

6-1.

GAS

METAL

ARC

(GMAW)

AND

FLUX

CORED

ARC

(FCAW)

WELDING

A

WARNING: ELECTRIC

SHOCK

can kill;

MOVING

PARTS

can

cause

serious

injury;

EXPOSURE

TO

ENVIRONMENT

can

damage

internal parts.

•

Do

not

touch

live

electrical

parts.

•

Keep

case

closed

while operating.

Warranty

is

void

if

the

wire

feeder

is

operated

with

any

portion

of

the

outer

enclosure open

or

removed.

ARC

RAYS

can

burn

eyes

and

skin; NOISE

can

damage hearing.

•

Wear

correct

eye,

ear,

and body

protection.

FUMES

AND

GASES can

seriously

harm

your

health.

•

Ventilate

to

keep

from

breathing

fumes

and

gases.

•

If

ventilation

is

inadequate,

use

approved

breathing

device.

HOT

METAL,

SPATrER,

AND

SLAG

can

cause

fire

and

burns.

•

Watch

for

fire.

•

Keep

a

fire

extinguisher

nearby

and

know

how

to

use

it.

•

Allow

work

and

equipment

to

cool

before

handling.

MAGNETIC

FIELDS

FROM

HIGH

CURRENTS

can

affect

pacemaker operation.

•

Wearers

should

consult

their

doctor

before

going

near

arc

welding

gouging,

or

spot

5-21

E

welding

operations.

WELDING

WIRE can

cause

puncture

Wounds.

•

Do

not

point

gun

toward

any

part of

the

body

any

conductive

surface,

or

other

personnel.

1.

Install

and

connect

unit

according

to Section

4.

2.

Wear

dry

insulating gloves

and

clothing.

3.

Connect

work

clamp

to

clean,

bare metal

at

work-

piece.

4.

Rotate

WIRE

SPEED

control

to

desired

position

(see

Section

5-2).

A

WARNING:

ELECTRIC

SHOCK

can kill.

•

Do

not

touch

live

electrical

parts.

•

Do

not

touch welding

wire

or

any

metal

part

in

contact

with

it

while

welding.

The

welding

wire

and all

metal

parts

in

contact

with

it

carry

weld

output when

the

welding

power

source

contactor

is

energized.

5.

Energize

the

welding

power

source

or

generator.

6.

Place

the

POWER switch

in

the

ON

position

7.

Turn

on

shielding

gas

at

the

source,

if

applicable.

8.

Wear

welding

helmet with

proper filter lens

according

to

ANSI Z49.1.

9.

Hold

tip

of gun

approximately

1/2 in.

(13

mm)

from

workpiece,

and

depress

gun

trigger.

Current

flows,

gas

flows,

and

wire

feeds.

If

wire

slippage

is

noticed,

adjust drive

roll

pressure

according

to

Section 4-7.

Access

Hole

For

Gun/Feeder

Connector

Gun

Trigger

Receptacle

Wire

Speed

Control

Figure

5-1.

Control

Panel

View

TM-1571

Page

9