8-4.

MOTOR BOARD

PCi

TESTING

INFORMA

-

TION

(Figure

8-1

And

Diagram 8-2)

A

W

ARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

•

Shut

down

wire

feeder and

welding

power

source

or

stop

engine

before

making

or

changing

meter

lea

d

connections

and

before

disconnecting

or

connecting

any

leads.

MOVING

PARTS

can

cause

serious

injury.

•

Keep

away

from

moving

parts.

HOT

SURFACES

can

cause

severe burns.

•

Allow

cooling

period

before servicing.

This

procedure requires the

unit

to

be

ener

-

~

ized.

Only

qualified

persons

familiar

with

and

ollowing

standard

safety practices

are

to

per-

form this

testing

procedure.

A

CAUTION:

ELECTROSTATIC

DISCHARGE

(ESD)

can

damage

circuit

boards.

•

Put

on

properly

grounded

wrist

strap

BE-

FORE

handling

circuit

boards.

•

Transport

circuit

boards

in

proper

static-

shielding

carriers

or

packages.

•

Perform

work

only

at

a static-safe

work

area.

INCORRECT

INSTALLATION

or

misaligned

plugs

can

damage

circuit board.

•

Be

sure

that

plugs

are

properly

installed

and

aligned.

EXCESSIVE

PRESSURE

can

break

circuit

board.

•

Use

only

minimal pressure and

gentle

move

-

ment

when

disconnecting

or

connecting

board

plugs

and

removing

orin

stalling

board.

IMPORTANT:

For all checks,

be

sure

to

test

and

verify

the

continuity

of

leads between

the

board

and

the

area

where

check

is

performed.

All

checks

should

go

through

the

connections

and be

actual

terminal-to-terminal

tests

so

that

bad

connections

or

leads

and

corrosion

are

not

the

problem.

A.

Preliminary

Checks

1.

Check

that

jumper

plug

PLGl

is

secure

in

recep

-

tacle

RC1

on

Motor

Control

Board

PCl.

2.

Check

that

plug

PLG2

is

secure

in

receptacle

RC2

on

Motor

Control

Board

PCl.

3.

Check

that

plug

PLG3

is

secure

in

receptacle

RC3

on

Motor

Control

Board

PCl.

4.

Check

that

plug

PLG4

is

secure

in

receptacle

RC3

on

Motor

Control

Board

PCi.

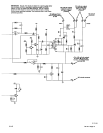

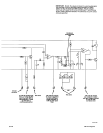

B.

Power

Supply

Circuit

Input power

of

24

volts ac

should

be

present

between

pins

A

and

B

of

receptacle

RC4.

If

24

volts ac

are

not

present,

check

POWER

switch

51

and

circuit

breaker

CBl

for

proper operation

with

an

ohmmeter.

An

output

voltage

of +24

volts dc

should

be

present at

pin A

of receptacle

RC2

with

respect

to

circuit

common.

If

+24

volts dc

are

not

present

at

pin

A,

replace

Motor

Control

Board

PCl.

An

output voltage

of

+6.5 volts dc

should

be

present

at

pin C

of

receptacle

RC2

with

respect

to

circuit

common

with

gun

trigger

pressed.

If +6.5 volts dc

are

not

present

at

pin C,

replace

Motor

Control

Board

PCi.

C.

Trigger

Circuit

When

the

gun

trigger

is

pressed, +19

volts dc

should

be

present

at

pin B

of

receptacle

RC2

with

respect

to

circuit

common

otherwise

the

voltage

at

pin

B

should

be

0 volts

dc

when

the

gun

trigger

is

not

pressed.

The

trigger

signal

is

then

supplied

to

pin A

of

receptacle

RCl

as a motor

start/stop

control signal

and

also supplied

to

pin

B

of

re

-

ceptacle

RCl

to

control

gas

valve

GS1

and

contactor

control relay

CR1

on

PCi.

D.

Wire

Feed Speed

Circuit

The

0

to

+6.5 volts dc

wire

feed

speed

command

input

signal

should

be

present

at

pin D

of

receptacle

RC2.

The

wire

feed

speed

command

signal

is

compared

to

the

current

and

voltage

feedback

from

Motor

Ml

thereby

providing the

proper

voltage

output

of

0

to +24

volts dc

to

wire

drive

motor

Ml

through

pins

D

(positive)

and C

(negative)

of

receptacle

RC4.

If

0

to +24

volts dc

is

not

present

between pins

C

and

D

of

RC4,

replace

Motor

Control

Board

PCi.

5-2iE TM-i57i

Page

17