10-2.

ALIGNING

DRIVE

ROLL

AND

WIRE

GUIDE

(Figure

10-1)

A

W

ARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

•

Shut

down wire

feeder and

welding

power

source,

and

disconnect

input

power

employing

lockout/tagging

procedures

be

ore

working

on

feeder.

Lockout/tag

9ing procedures

for wire

feeder

consist

of

disconnecting

interconnecting

cord,

and

for

welding

power

source consist

of

pad

-

lockin9

line

disconnect switch

in

open

position,

removing

fuses

from

fuse

box,

or

shutting

off

and

red-tag9ing

circuit

breaker

or

other

discon

-

necting device.

Stop

engine,

and

disconnect

negative

(—)

battery

cable

from battery

on

weld-

ing

generators.

MOVING

PARTS

can

cause

serious

injury.

•

Keep

away

from

moving

parts.

HOT

SURFACES

can

cause

severe

burns.

•

Allow

cooling

period

before servicing.

Maintenance

to

be

performed

only

by

qualified

persons.

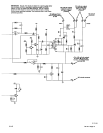

The

drive

roll and

wire

guide

must

be

aligned

for wire

to

feed

properly.

Alignment

is

factory set

and

should

not

re

-

quire

readjustment.

To

check

alignment,

compare

drive

roll and

wire

guide positions

with

Figure

10-1.

If

align

-

ment

is

necessary,

proceed

as follows:

Behind

the drive

roll

mounting

hub

is

a

spring washer.

To

obtain

proper

alignment

of

the drive

roll

with

the

wire

guide,

rotate

drive

roll

mounting

hub

securing bolt,

and

move

drive

roll

in

or

out

until

groove

in

drive

roll

lines

up

with

wire

guide

(see

Figure

10-1).

Wire

Guide_-

CORRECT

A

ALIGNMENT

Drive

Roll

Washer

INCORRECT

ALIGNMENT

Secrurlng

Bolt

Welding Wire

V

Drive

Roll

Mounting

Hub

View

Is

from

top

of

feeder

looking

down

with

pressure

roll

assembly

open

I

SA

145763

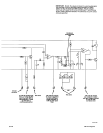

10-3.

REINSTALLATION

OF HUB

ASSEMBLY

(Fig

-

ure

10-2)

A

WARNING: ELECTRIC

SHOCK

can

kill.

•

Do

not

touch

live

electrical

parts.

•

Shut

down

wire

feeder and

welding

power

source,

and

disconnect

input

power

employ

-

ing

lockout/tagging

procedures

before

work

-

ing

on

feeder.

Lockout/tagging procedures

for wire

feeder

con-

sist

of

disconnecting

interconnecting

cord,

and

for

welding

power

source consist

of

padlocking

line

disconnect

switch

in

open

position,

remov

-

ing

fuses

from

fuse box,

or

shutting

off

and

red

-

tagging

circuit

breaker

or

other

disconnecting

device.

Stop

engine,

and

disconnect negative

(—)

battery

cable

from

battery

on

welding

gen

-

erators.

If

it

should

become necessary

to

replace

any

part

of

the

assembly,

obtain

part and

proceed

as follows

to reinstall

the

assembly.

1.

Slide the

following

items

onto

the

spool

support

shaft

in

order

given:

a.

Fiber

Washer

b.

Brake

Washer

c.

Hub

d.

Brake

Washer

e.

Fiber

Washer

f.

Keyed

Washer

g.

Spring

h.

Wire

Reel

i.

Wire

Retainer

j.

Spanner

Nut

k.

Retaining

Ring

2.

Rotate

bolt into

support

shaft.

Bolt should

be

ro

-

tated

only

until

a

slight

drag

is

felt while

turning

hub.

3.

Install

retaining

ring

on

hub.

10-4.

BRUSH

INSPECTION

AND

REPLACEMENT

A

WARNING: ELECTRIC

SHOCK

can

kill.

•

Do

not

touch

live

electrical

parts.

•

Shut

down wire

feeder

and

welding

power

source,

and

disconnect

input

power

employ

-

ing

lockout/tagging

procedures

before

work

-

ing

on

feeder.

Lockout/tagging procedures

forwire

feedercon

-

sist

of

disconnecting

interconnecting

cord,

and

for

welding

power

source

consist

of

padlocking

line

disconnect

switch

in

open

position,

remov

-

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

Stop

engine,

and

disconnect negative

(—)

battery

cable

from

battery

on

welding

gen

-

erators.

Figure

10-1.

Reinstallation

Of

Hub

Assembly

TM-1571 Page

26

1.

Remove

two

brush caps

located

on

end of

the

drive

motor.

S-21E