OM-169 510 Page 2

IMPORTANT:

When installing or operating plasma arc

welding equipment, refer to the Plasma Welding Con-

sole Owner’s Manual and Welding Torch Owner’s

Manual for specific precautionary information that ap-

plies to this equipment.

3-1. FIELD INSTALLATION INSTRUCTIONS FOR

PAW INTERFACE PANEL TO COMPUTER IN-

TERFACE (Figure 3-1 And Figure 3-2)

WARNING: ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down robot and welding power source,

and disconnect input power employing lock-

out/tagging procedures before beginning

this installation.

Lockout/tagging procedures consist of pad-

locking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other discon-

necting device.

CAUTION: ELECTROSTATIC DISCHARGE

(ESD) can damage circuit boards.

•

Put on properly grounded wrist strap BE-

FORE handling circuit boards.

•

Perform work only at a static-safe work area.

INCORRECT INSTALLATION or misaligned

plugs can damage circuit board.

•

Be sure that plugs are properly installed and

aligned.

EXCESSIVE PRESSURE can break circuit

board.

•

Use only minimal pressure and gentle move-

ment when disconnecting or connecting

board plugs and removing or installing board.

IMPORTANT:

All directions, such as left or right, are

with respect to the operator facing the Computer Inter-

face front panel. Retain all hardware removed during

this procedure for reinstallation unless specifically told

otherwise.

1. Remove Computer Interface top cover and left

side panel.

2. Remove side panel from PAW Interface panel.

3. Install PAW Interface frame onto left side panel of

Computer Interface with sheet metal screws re-

moved in Step 1 (see Figure 3-1).

4. Make the following internal connections to the

Computer Interface (see Figure 3-2).

a. Remove jumper link between terminals B and C

on terminal strip 2T.

b. Connect lead 26 from the Interface panel to ter-

minal B on terminal strip 2T.

c. Connect lead 60 from the Interface panel to top

mounting screw on filter FL1.

d. Connect green lead from the Interface panel to

the ground stud located directly above terminal

strip 2T.

IMPORTANT:

Remove the outside star washer from the

ground stud to make room for the green lead terminal.

e. Remove plug PLG3 from receptacle RC1 on In-

terface Board PC4.

f. Connect plug PLG10 from the PAW Interface

panel to Interface Board PC4 receptacle RC1

where plug PLG3 was removed in Step 4e (plug

PLG3 is not connected for this application).

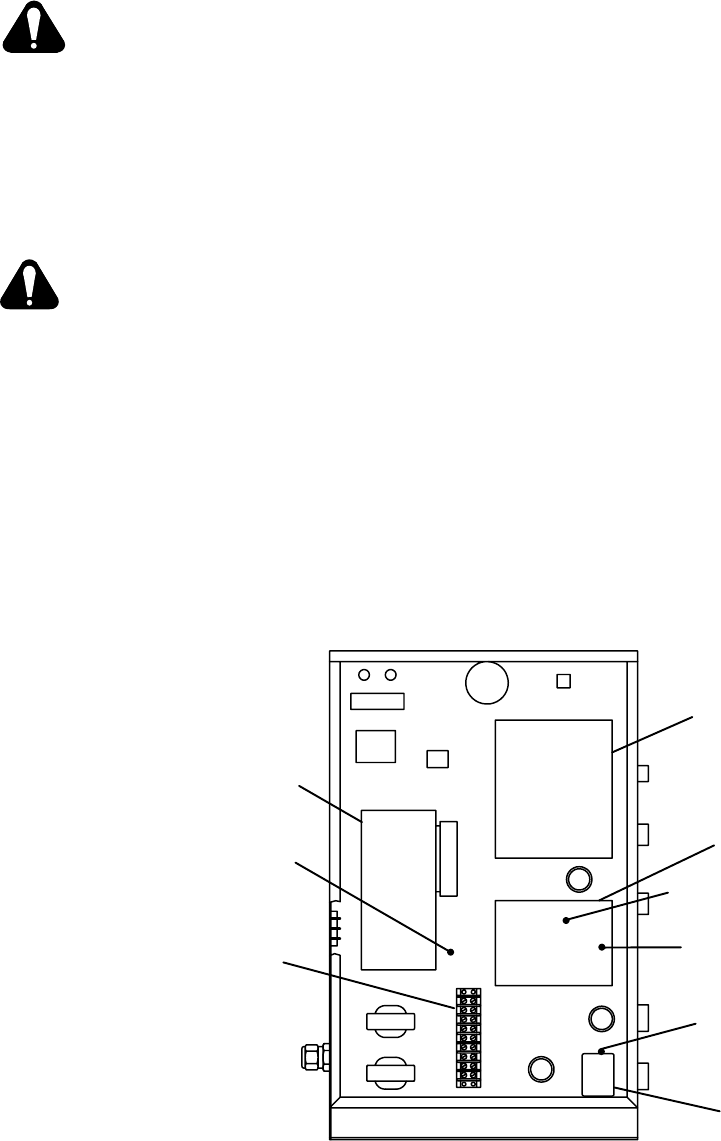

Ground Stud

Location

Motor Control

Board PC2

Terminal

Strip 2T

Filter FL1

Mounting Screw

Location

Interface

Board PC4

Voltage Control

Board PC1

PC4 Receptacle RC1

Location

Left Side View Of

Computer Interface

Ref. ST-139 887-C

PC4 Switch S1 Location

Figure 3-2. Computer Interface Internal Connections