3 Installation

MITSUBISHI CNC

62

3.1 Heat Radiation Countermeasures

Please refer to the following method for heat radiation countermeasures.

Example of heat radiation countermeasures

<Hypothetical conditions>

(1) Average internal temperature of operation panel: T ≤ 55°C

(2) Peripheral temperature of operation panel : Ta ≤ 0°C to 45°C

(3) Internal temperature rise value : ΔT = T - Ta (max) = 10°C

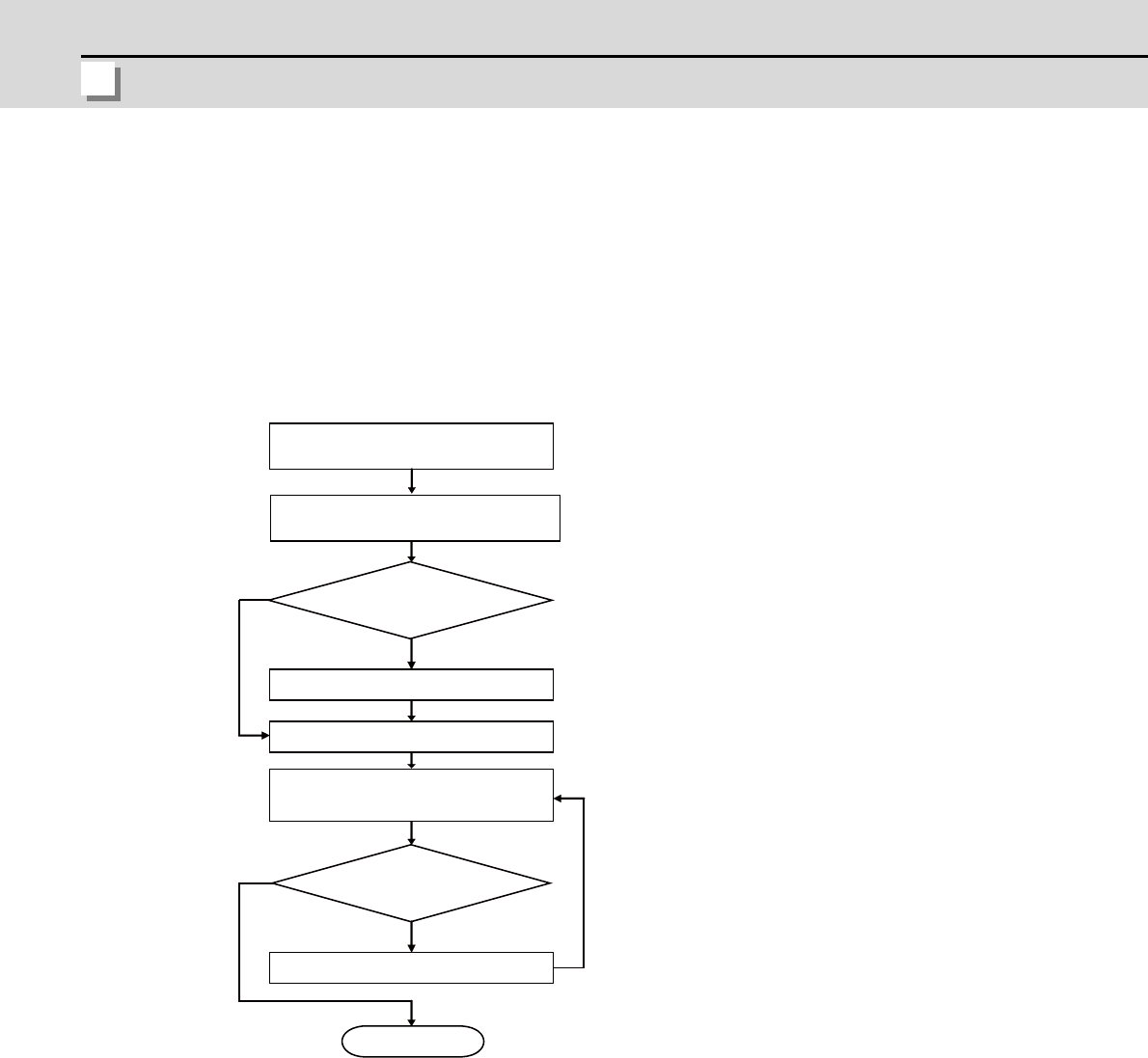

Procedures for heat design and verification

<Supplement>

(1) Refer to "General Specification" for the heat generated by each unit.

(2) Enclosed cabinet (thin steel plate) cooling capacity calculation equation

W1 = U × A × ΔT

U: 6 W/m

2

°C

A: Effective heat radiation area (m

2

) (Area where heat can be radiated from operation panel)

ΔT: Internal temperature rise value (10°C)

(Caution) 8 W/m

2

°C can be applied only when the operation panel is so small that the internal

temperature stays uniform.

(3) Points of caution for heat radiation countermeasures when designing mounting state

- Consider convection in operation panel (eliminate heat spots)

- Collect hot air at suction port of heat exchanger in operation panel.

(4) Criterion for internal temperature rise distribution data

ΔT (average value) ≤ 10°C

ΔTmax (maximum value) ≤ 15°C

R (inconsistency ΔTmax - ΔTmin) ≤ 6°C

(Evaluate existence of heat spots)

W

≤

W1

W>W1

ΔT

≤

10°C

ΔT>10°C

Calculate total heat radiation of each

mounted unit (W)

Comparison of W and W1

Collection of internal temperature rise

distribution data

Mounting design

Improvements

Completion

Selection of heat exchanger

Evaluation

Calculate cooling capacity of

operation panel (W1)