12

Adjustments

Disconnect jointer from

power supply before making adjustments.

Drive Belt Tension

To check the tension of the drive belts:

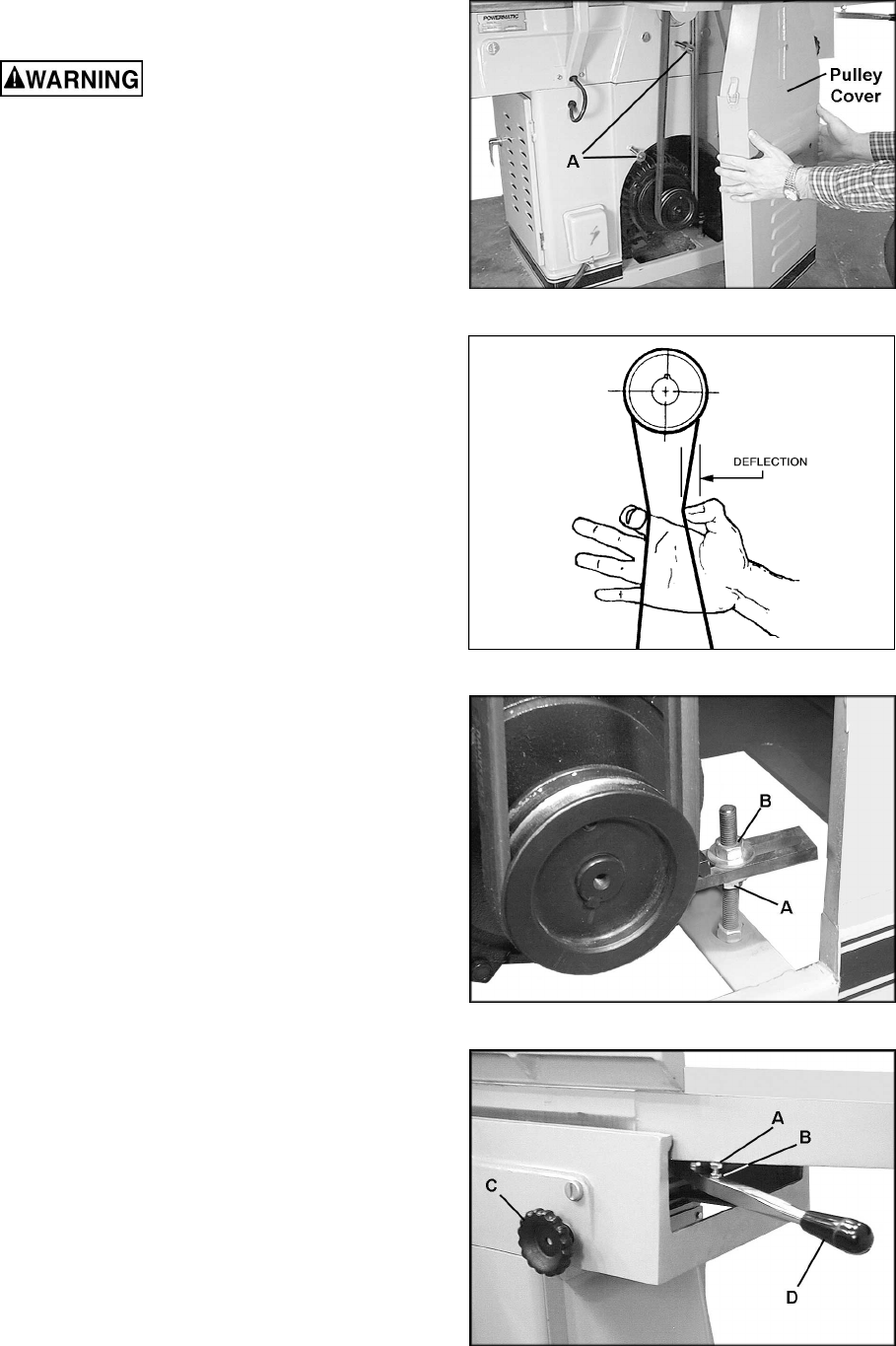

1. Remove the three cap nuts and flat washers

on the pulley cover with a 9/16 wrench, and

remove the guard to expose the belts and

pulleys. See Figure 9.

NOTE: The hex nuts and flat washers on the

threaded rods (A, Figure 9) should be left in

place; they keep the pulley cover from bending

as it is being tightened back into place with the

cap nuts.

2. There should be a small amount of

deflection in the belt when pressing it

midway between the pulleys with moderate

finger pressure (Figure 10).

3. If the belts need tightening, loosen the lower

hex nut (A, Figure 11) on the motor base

with a 19mm wrench.

4. Turn the top hex nut (B, Figure 11)

clockwise until proper tension is achieved.

5. Retighten lower hex nut (A, Figure 11).

NOTE: The belts should be inspected again

after the first few times the machine is used, as

the belts may stretch slightly during the

“breaking-in” process.

Setting Outfeed Table Height

For accurate work in most jointing operations,

the outfeed table must be exactly level with the

knives/inserts at their highest point of revolution.

The outfeed table on the Model 1285 has been

pre-set at the factory to the proper height in

relation to the cutterhead. However, the level of

the outfeed table should be checked in case of

slight misadjustment during shipping. Outfeed

table height should also be inspected after re-

setting or replacing knives/inserts.

1. The outfeed table has a stop screw (A,

Figure 12) which, when contacting the edge

of the table as shown, will ensure the

outfeed table is at the proper height. Loosen

the handwheel (C, Figure 12) and raise the

outfeed table adjustment arm (D, Figure 12)

until this stop screw (A, Figure 12) contacts

the edge of the table as shown.

Figure 9

Figure 10

Figure 11

Figure 12