21

Maintenance

Disconnect machine from

power source before performing any

maintenance. Failure to comply may cause

serious injury.

Check all screws and fasteners occasionally and

keep them tightened securely.

Inspect cords; a cord that is frayed or damaged

in any way should be replaced immediately.

The table and fence surfaces must be kept

clean and free of rust for best results. Some

users prefer a paste wax coating. Another option

is talcum powder applied with a blackboard

eraser rubbed in vigorously once a week; this

will fill casting pores and form a moisture barrier.

This method provides a table top that is slick

and allows rust rings to be easily wiped from the

surface. Important also is the fact that talcum

powder will not stain wood or mar finishes as

wax pickup does.

Lubrication

The cutterhead runs in two single-row sealed

and shielded ball bearings, which are pre-

lubricated for life - no maintenance is necessary.

Occasionally apply a good grade of light grease

to areas of the jointer where friction may occur,

such as when the tables are raised or lowered.

Cutterhead Repairs

The entire cutterhead assembly may be

removed for bearing replacement or other

cutterhead maintenance procedures. The

procedure is identical for both helical and

straight cutterheads.

To remove the cutterhead:

1. Disconnect machine from power source.

2. Remove rabbeting ledge and fence.

3. Lower infeed and outfeed tables until they

are clear of the cutterhead.

4. Remove belts.

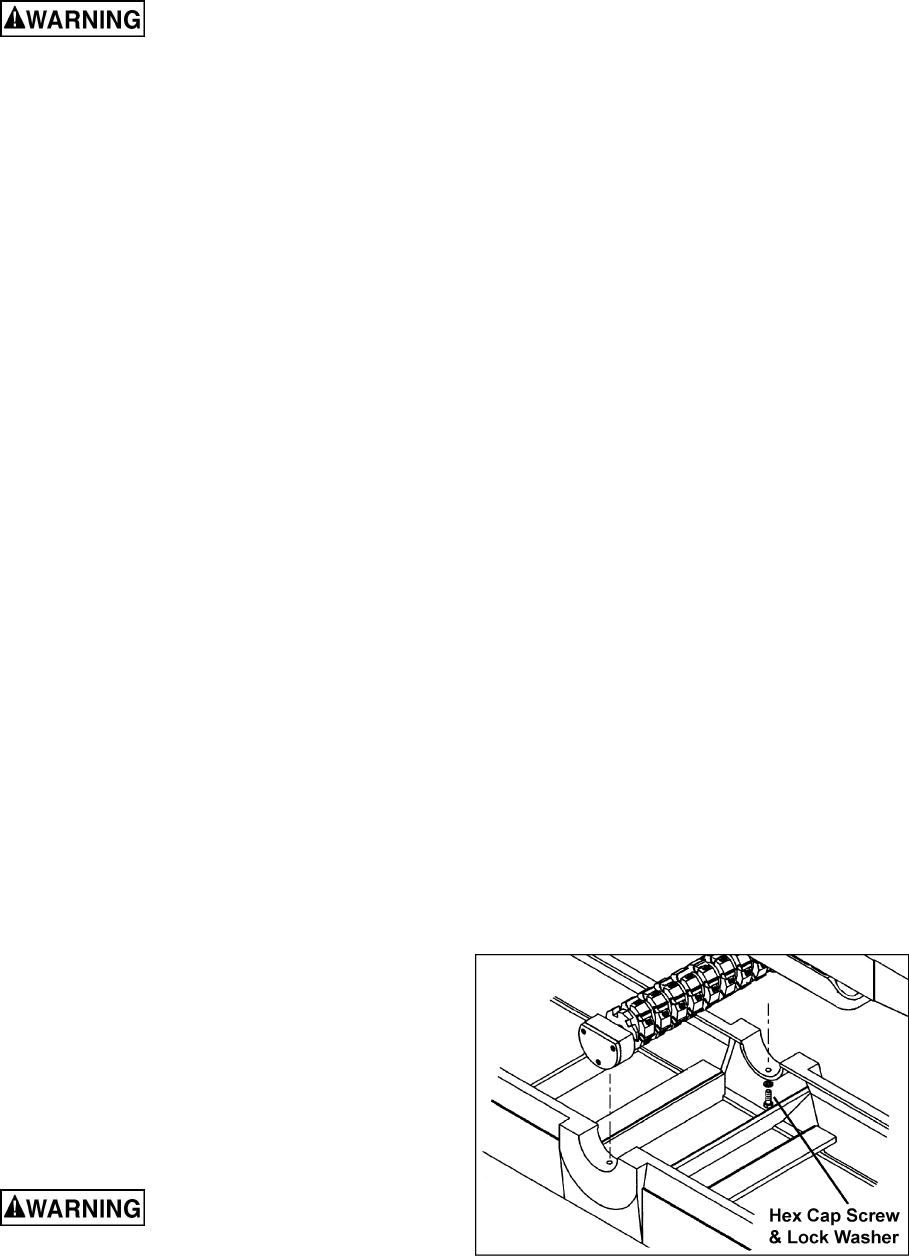

5. Remove the two hex cap screws and lock

washers that hold the cutterhead to the bed

– these are accessed from the underside of

the bearing blocks as shown in Figure 32.

Before removing cutterhead,

wrap it with several cloths to prevent

personal injury.

Figure 32