23

Whetting Knives (Straight

Cutterhead)

When knives become dull enough so that it is

noticeable when cutting, they should be

resharpened or replaced. A sharp knife will work

easier and last longer. The penalty paid for a

dull knife is less blade life and greater wear and

tear on all parts of the machine.

Jointer knives are very

sharp. Use care and proceed slowly when

working with or around the cutterhead.

1. Disconnect machine from power source.

2. Remove the pulley cover so you can rotate

the cutterhead by means of the belts.

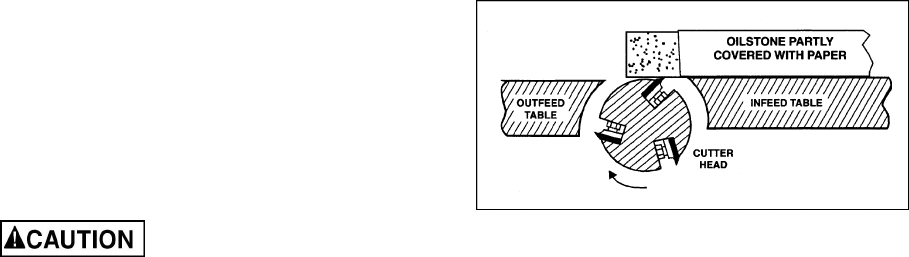

3. Use a fine carborundum stone. Cover it

partly with paper, as shown in Figure 34, to

avoid marking the table.

4. Lay the stone on the infeed table. Adjust the

infeed table and turn the cutterhead until the

stone lies flat on the bevel of the knife and

flat on the infeed table.

5. Hold the cutterhead from turning, and whet

the beveled edge of the knife, stroking

lengthwise by sliding the stone back and

forth across the table. Do the same amount

of whetting on each of the three knives.

6. When finished, reset the knives parallel to

the outfeed table. See “Setting Knives

(Straight Cutterhead)”.

If knives cannot be properly retouched as

described above, they must be ground and re-

surfaced to a new bevel edge. Check in the

phone directory under “Sharpening Service” or

“Tool Grinding or Sharpening.” It may be less

expensive to purchase a new set of knives. If

the jointer is used often, keeping a spare set of

knives on hand is recommended.

Knives (stock no. 6292535) may be ordered

from your authorized Powermatic distributor or

by calling 1-800-274-6848.

Gum and Pitch which collect on the knives

cause excessive friction as the work continues,

resulting in overheating of the knives, less

efficient cutting, and consequent loss of blade

life. Use "Gum and Pitch Remover" or oven

cleaner, to carefully wipe off the knives.

Figure 34