22

6. Slide the cutterhead out the rabbeting side.

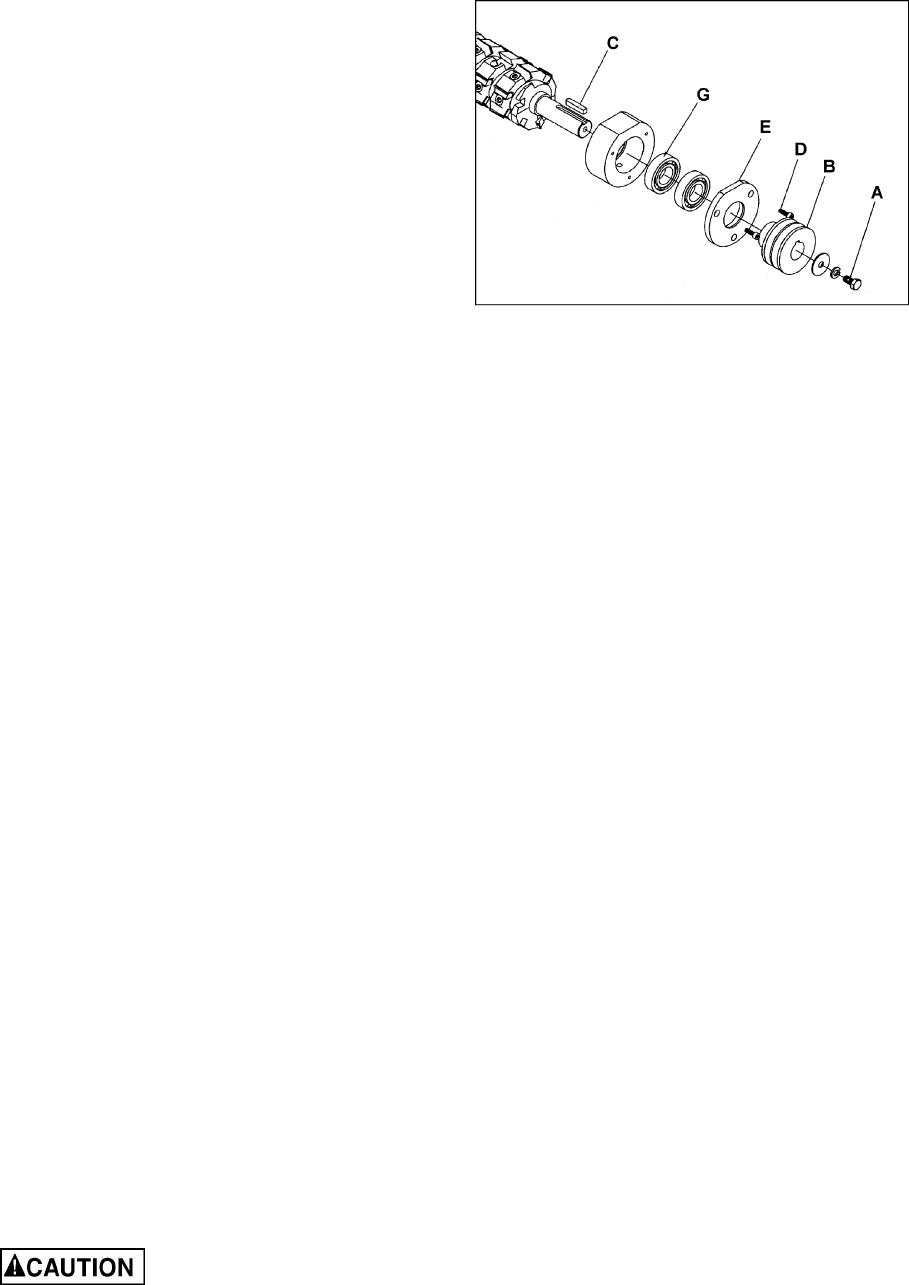

7. Loosen hex cap screw (A, Figure 33) and

remove pulley (B, Figure 33) and key (C,

Figure 33).

8. Loosen screws (D, Figure 33) on both sides

and remove bearing cap plates (E, Figure

33).

NOTE: Figure 33 shows the pulley end of

the cutterhead. The procedure is similar for

breaking down the opposite end of the

cutterhead - refer to assembly drawing on

page 39 for the specific parts.

IMPORTANT: If the bearings (G, Figure 33)

need replacement, it is strongly recommended

this be done by qualified service personnel. The

bearings are press fitted and must be removed

with an arbor press.

9. To re-install the cutterhead, reverse the

above procedure. NOTE: Before re-

installing, make sure the machine’s curved

seats of the base casting are free of dirt,

dust or grease, which will help ensure a tight

fit.

Knife Inserts (Helical Cutterhead)

When knife inserts become dull enough so that

it is noticeable when cutting, they should be

turned over or replaced entirely. A sharp knife

works easier and results in longer blade life. The

penalty paid for a dull knife is less blade life and

greater wear and tear on all parts of the

machine.

An advantage of the helical style cutterhead is

that if knife inserts develop nicks, these inserts

can be individually flipped or replaced without

the need to disturb the other inserts. See

“Replacing Knife Inserts (Helical Cutterhead)”

for this procedure.

If the jointer is used often, keeping a spare set

of knife inserts on hand is recommended. Knife

inserts (stock no. 6400013) may be ordered

from your authorized Powermatic distributor or

by calling 1-800-274-6848.

Gum and pitch which collect on the knife inserts

cause excessive friction as the work continues,

resulting in overheating of the inserts, less

efficient cutting, and consequent loss of blade

life. Use "Gum and Pitch Remover" or oven

cleaner, to carefully wipe off the knife inserts.

Jointer knife inserts are very

sharp. Use care and proceed slowly when

working with or around the cutterhead.

Figure 33