13

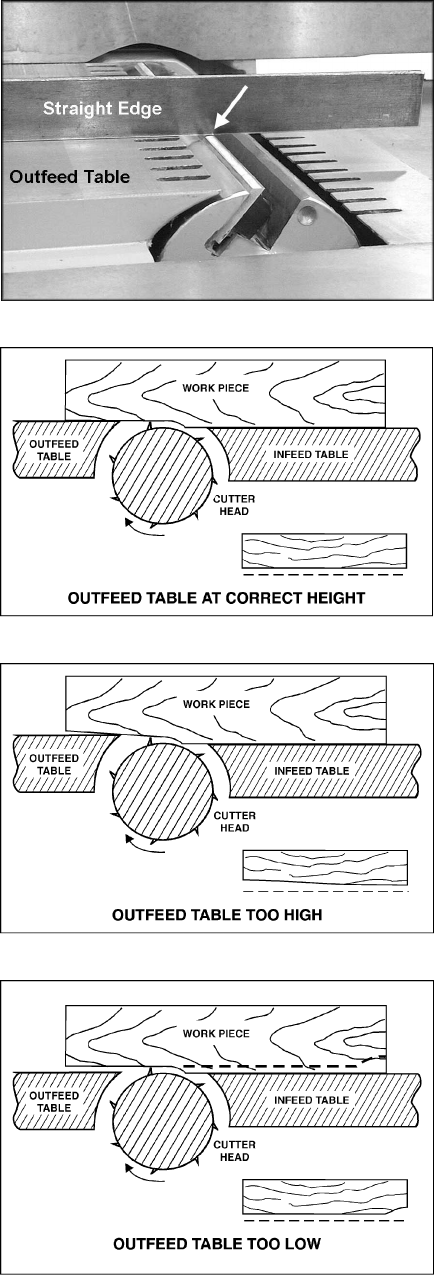

2. Place a straight edge on the outfeed table

and extending over the cutterhead, as

shown in Figure 13.

3. Rock the cutterhead slightly so that a knife

tip contacts the straight edge. If the knife tip

just contacts the straight edge without

moving the straight edge, then the outfeed

table is at the proper height. If the knife tip

pushes up the straight edge, the outfeed

table is too low. If the knife tip does not

contact the straight edge, the outfeed table

is too high.

4. To raise the height of the outfeed table,

loosen the hex nut (B, Figure 12) and rotate

the stop screw (A, Figure 12) clockwise. To

lower the height of the outfeed table, rotate

the stop screw (A, Figure 12) counter

clockwise.

5. When the outfeed table is level with the

knives, tighten the hex nut (B, Figure 12)

and firmly tighten the handwheel (C, Figure

12).

After the outfeed table has been set, it should

not be changed except for special operations.

As a final check of the outfeed table adjustment,

turn on the jointer and run a scrap piece of wood

slowly over the knives for 6 to 8 inches; the

wood should rest firmly on both tables, as

shown in Figure 14, with no open space under

the finished cut.

If the outfeed table is too high, the finished

surface of the workpiece will be curved (Figure

15).

If the outfeed table is too low, the workpiece will

be gouged at the end of the cut (Figure 16).

Make further changes to the stop screw if

necessary to ensure the outfeed table is level

with the knives/inserts.

Figure 13

Figure 14

Figure 15

Figure 16