16

Replacing Knife Inserts (Helical

Cutterhead)

Jointer knife inserts are very

sharp. Use care and proceed slowly when

working with or around the cutterhead.

The helical cutterhead is a solid steel design

that holds 44 two-sided knife inserts, and two

rabbet knife inserts on the outboard end of the

cutterhead. Replacing knife inserts is a simple

process, and they will seat themselves properly

without having to be set with a knife gauge.

After a period of use, dull knife inserts should be

flipped over to present a new edge. If both

edges are worn, knife inserts should be

replaced.

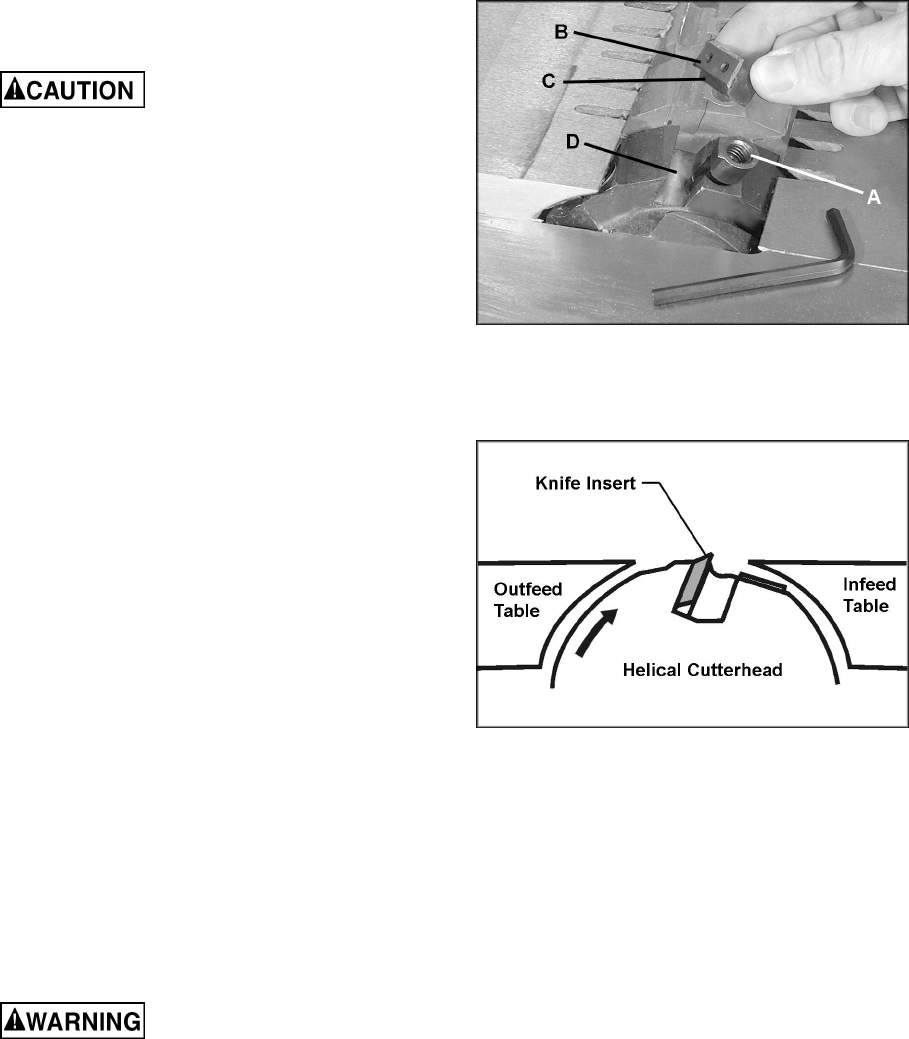

1. Loosen the gib screw (A, Figure 20).

2. Remove the knife insert (B, Figure 20) with

the gib (C, Figure 20) from its slot.

3. Make sure the slot (D, Figure 20) is free of

dust and debris that would prevent the gib

and insert from seating properly. Wipe out

the slot and clean with solvent if needed.

4. Flip the knife insert 180 degrees and place it

onto the two pins of the gib. Make sure the

knife edge faces the proper direction (see

Figure 21).

5. Re-install the gib into the slot.

6. Firmly tighten the gib screw (A, Figure 20).

NOTE: To ensure optimal cutting, all knife

inserts in the cutterhead should be flipped at the

same time. Of course, if an insert is nicked or

damaged, it can be flipped or replaced

individually as needed.

After installing a knife insert, be sure to tighten

the gib screw before moving on to the next knife

insert.

Make certain the direction of

knife inserts is correct, and all gib screws

are tightened securely. Loose gib screws

can result in knife inserts being thrown from

the cutterhead, causing severe damage to

the machine and possible serious or fatal

injury to the operator or bystanders.

Figure 20

Figure 21