5

blahblahblah

19. Keep visitors a safe distance from the work area. Keep children away.

20. Make your workshop child proof with padlocks, master switches or by removing starter keys.

21. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

22. Maintain a balanced stance at all times so that you do not fall or lean against the knives or other

moving parts. Do not overreach or use excessive force to perform any machine operation.

23. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for

which it was not designed. The right tool will do the job better and safer.

24. Use recommended accessories; improper accessories may be hazardous.

25. Maintain tools with care. Keep knives sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

26. Turn off the machine before cleaning. Use a brush or compressed air to remove chips or debris — do

not use your hands.

27. Do not stand on the machine. Serious injury could occur if the machine tips over.

28. Never leave the machine running unattended. Turn the power off and do not leave the machine until

the cutterhead comes to a complete stop.

29. Remove loose items and unnecessary work pieces from the area before starting the machine.

30. Never surface stock less than 12 inches long, or 3 inches wide, or 3 inches thick without a hold-down

or push block.

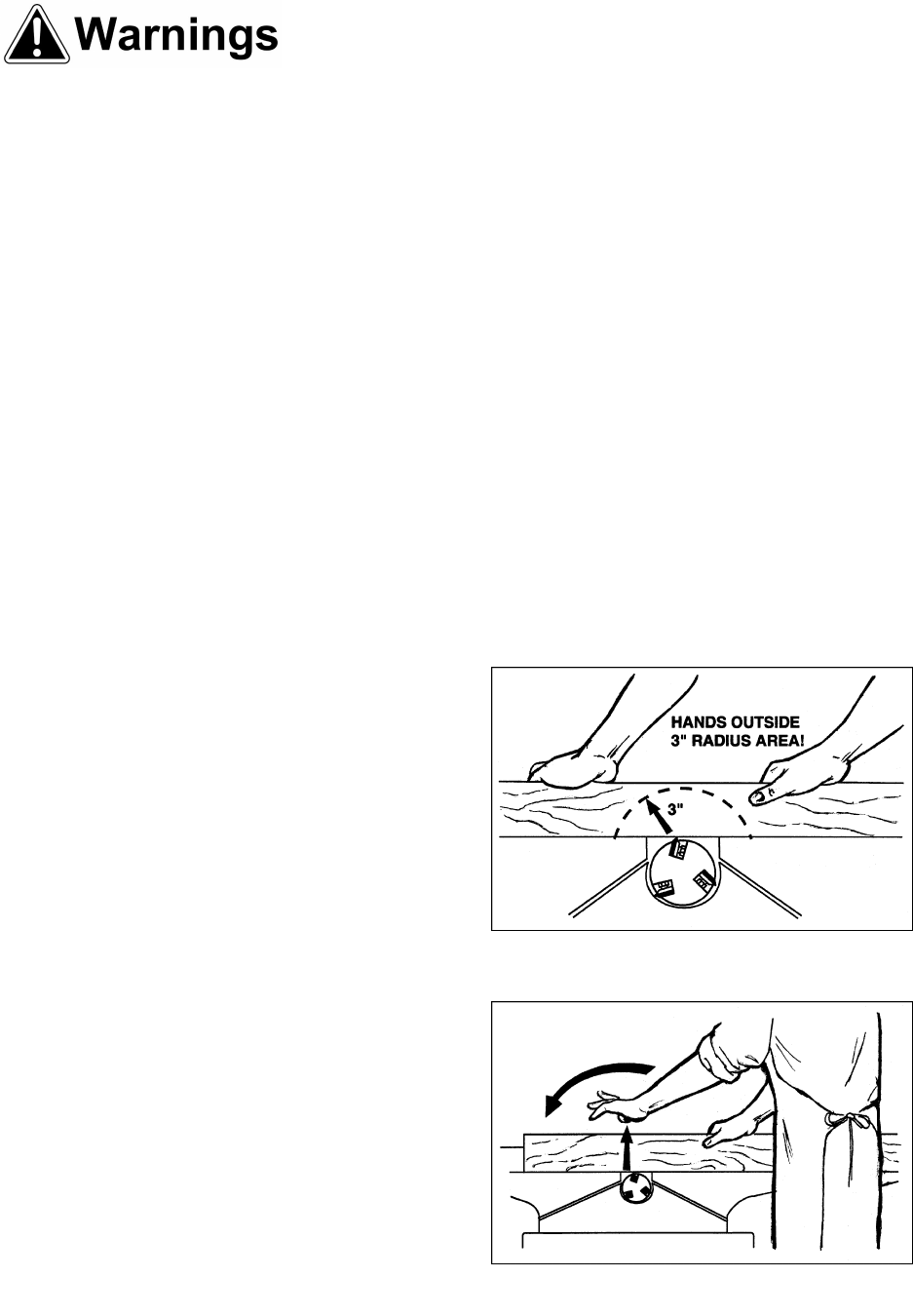

31. When working on the jointer, follow the 3-inch

radius rule. The hands must never be closer than

3 inches to the cutterhead. See Figure A.

32. Use extra care in the location of the jointer in the

shop. Position the jointer so that potential kicked

back stock will strike a wall and not endanger

other persons in the area.

33. Never apply pressure to stock directly over the

cutterhead. This may result in the stock tipping

into the cutterhead along with the operator’s

fingers. Follow the 3-inch rule. Position hands

away from extreme ends of stock, and push

through with a smooth, even motion.

34. “Pull-out” and the danger of kicked back stock can

occur when the work piece has knots, holes, or

foreign materials such as nails. It can also occur

when the stock is fed against the grain on the

jointer. The grain should run in the same direction

you are cutting.

35. It is good practice to move the hands in an

alternate motion from back to front as the work

continues through the cut. Never pass the hands

directly over the cutter knife. As one hand

approaches the knives, remove it from the stock in

an arc motion and place it back on the stock in a

position beyond the cutter knife. See Figure B. At

all times hold the stock firmly.

F

igure A

F

igure B