14

Setting Infeed Table Height (Depth of

Cut)

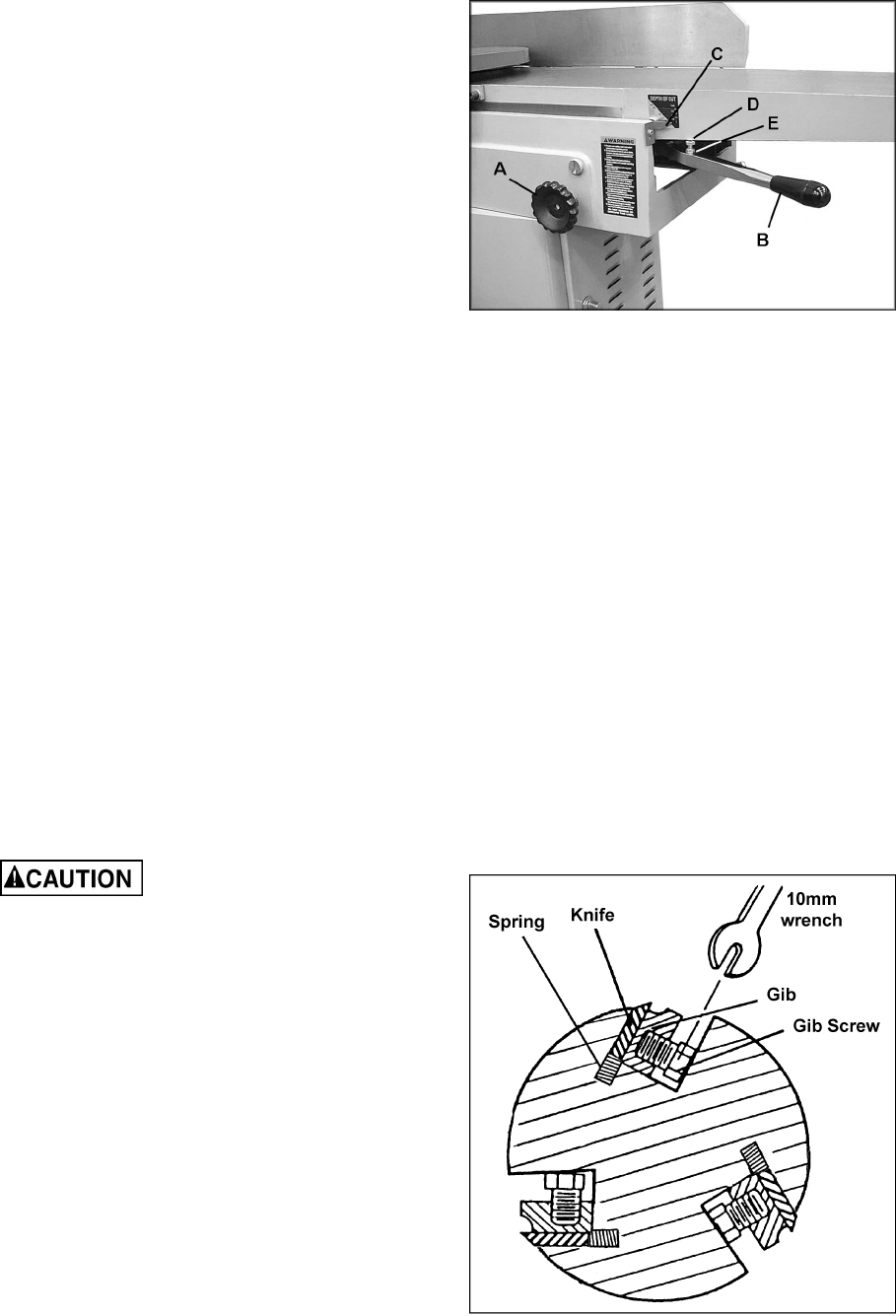

1. To set the cutting depth, loosen handwheel

(A, Figure 17) by turning counterclockwise.

2. Move table adjustment arm (B, Figure 17)

up or down to raise or lower infeed table.

The pointer (C, Figure 17) shows the depth

of cut on the adjoining scale.

3. Tighten handwheel securely (A, Figure 17).

The stop screw (D, Figure 17) on the infeed

table should be set so that when it contacts the

table, the infeed table will be exactly level with

the knives (with the scale pointer at zero). The

setting of this stop screw has been made at the

factory, but should be checked by the operator

before using the jointer. It should also be

checked occasionally as the machine receives

use.

Use the same procedure as for the outfeed

table, placing the straightedge across outfeed

table, cutterhead and infeed table. Loosen the

hex nut (E, Figure 17) and adjust the stop screw

(D, Figure 17) as necessary. When finished,

retighten hex nut (E, Figure 17).

If the infeed table is level with the knives but the

scale pointer (C, Figure 17) appears to be off,

loosen the scale pointer with a screwdriver and

adjust it as needed until it reads zero. Retighten

the screw.

Replacing and Setting Knives

(Straight Cutterhead)

Jointer knives are very

sharp. Use care and proceed slowly when

working with or around the cutterhead.

After a period of use, dull knives should be

reground or replaced. Remove the pulley cover

at the rear of the machine – this will allow you to

rotate the cutterhead by using the belts.

To remove a knife:

1. Disconnect machine from power source.

2. Back the fence away from the cutterhead as

far as it will go. Lower infeed and outfeed

tables.

3. Turn the six gib screws (Figure 18) into the

gib with a 10mm wrench. As the pressure of

the gib is released, the two springs in the

cutterhead slot will cause the knife to rise.

4. Carefully remove the knife from the

cutterhead.

Figure 17

Figure 18