10

Read and understand all

instructions before attempting assembly or

operation of band saw. Failure to comply may

cause serious injury.

7.0 Setup and assembly

7.1 Unpacking

1. Remove all contents from shipping carton. Do

not discard any shipping material until band

saw is assembled and running satisfactorily.

2. Inspect contents for shipping damage. Report

any damage immediately to your distributor

and shipping agent.

3. Compare contents of shipping carton with the

contents list in this manual. Report shortages,

if any, to your distributor.

Note: Some parts may have come pre-assembled

to the saw.

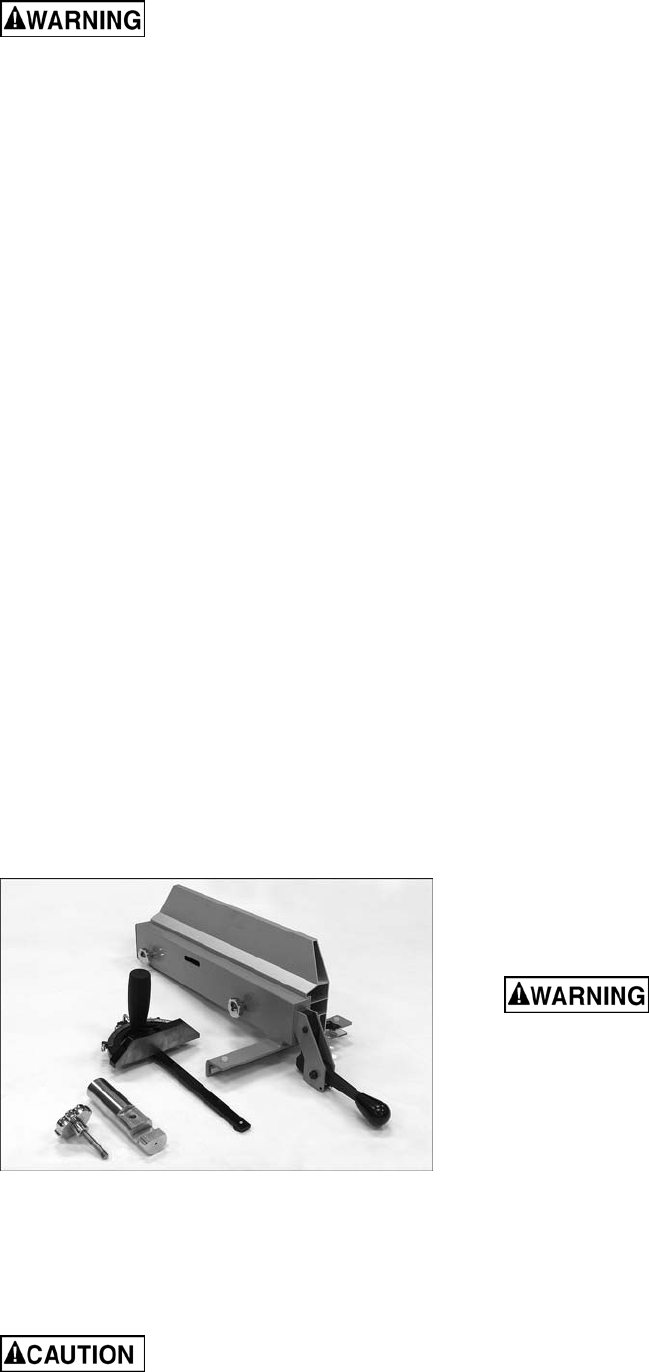

7.2 Shipping contents

Carton contents (see Figure 3):

1 Band saw (not shown)

1 Fence assembly with aluminum fence plate

1 Miter gauge

1 Resaw pin and handle

1 Owner’s manual (not shown)

1 Warranty card (not shown)

Tools required for set up and assembly:

Hoist or forklift, with straps

Machinist square

Figure 3

7.3 Location

Remove all crating and plastic from around

machine. Remove any screws or straps holding

band saw to shipping pallet.

Exercise care when removing

machine from shipping pallet.

Use a hoist or forklift with straps to remove band

saw from pallet. The straps used should have a

minimum 500-lb. lifting capacity. Do NOT place

forks or straps directly beneath table or against

handles or levers – use the lifting eye atop the

band saw.

Move band saw to its permanent location, which

should be dry and well lit, with a level floor and

enough space on all sides to handle long stock or

perform routine maintenance on the machine.

Make sure floor is able to support weight of

machine. If desired, band saw can be secured to

floor using lag screws (not provided) through the

four holes in base. See Figure 2 for hole spacing.

Exposed metal surfaces, such as table surface and

blade guides, have been given a protective coating

at the factory. This coating should be removed with

a soft cloth moistened with solvent. Do not get

solvents near plastic or rubber parts; and do not

use an abrasive pad as it may scratch exposed

surfaces.

The handle on the front handwheel may be in

reverse position for shipping. Reinstall it in proper

position on the handwheel. Use a wrench on the

flat to tighten it to the handwheel.

7.4 Dust Collection

The use of a dust collection system is strongly

recommended for this band saw. It will help keep

the shop clean, as well as reduce potential health

hazards caused by inhalation of wood dust. The

collector should have a capacity sufficient for this

size machine – 400 CFM is recommended.

Powermatic has a line of dust collection systems

available; see your dealer or visit our website listed

on the cover.

Connect the hoses of your dust collection system

to the saw’s dust ports (4” outside diameter).

Secure tightly with hose clamps (not provided).

7.5 Electrical Connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

The band saw is factory wired for 230 volts. It is

recommended that the band saw be connected to

a grounded and dedicated 20 amp circuit with a 20

amp circuit breaker or time delay fuse. Local codes

take precedence over recommendations.

7.6 Grounding Instructions

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having