11

an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. Do not modify the plug provided - if it

will not fit the outlet, have the proper outlet installed

by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-

grounding conductor to a live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to whether

the tool is properly grounded. Use only 3-wire

extension cords that have 3-prong grounding plugs

and 3 pole receptacles that accept the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150 – 250 volts, inclusive:

This tool is intended for use on a circuit that has an

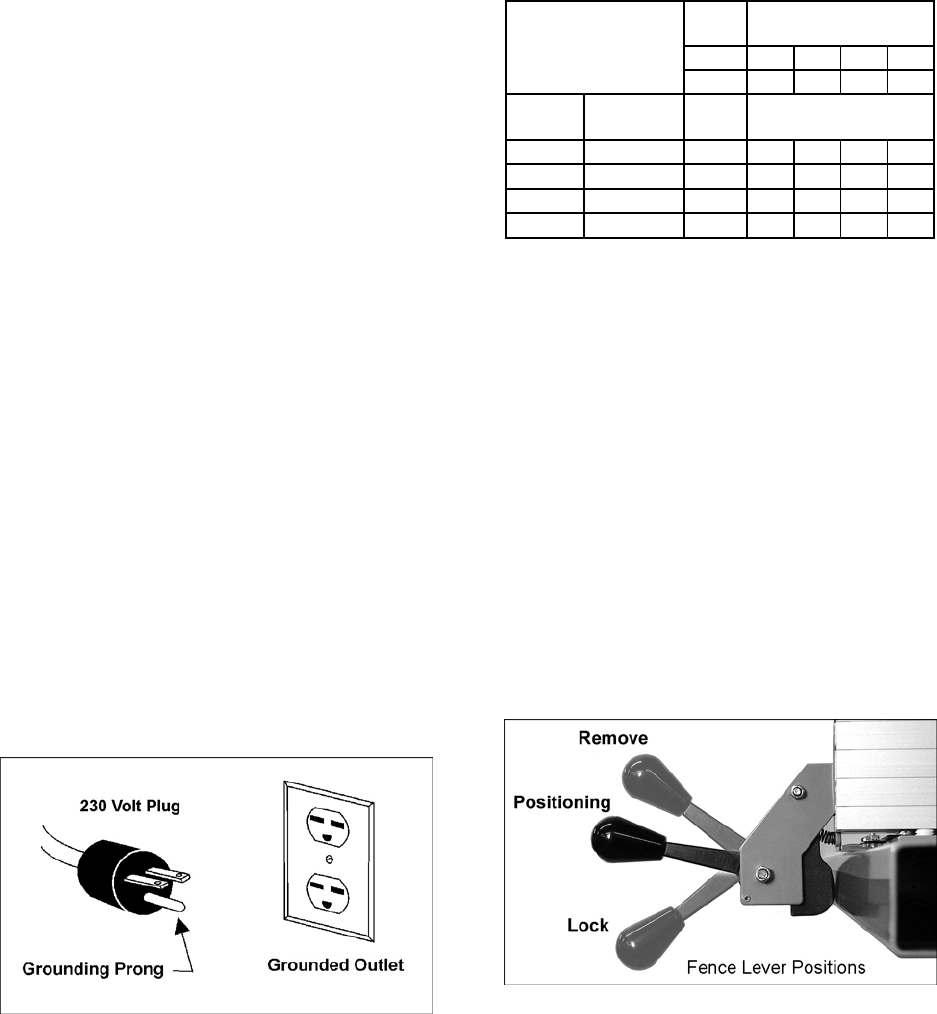

outlet that looks like the one illustrated in Figure 4.

The tool has a grounding plug that looks like the

plug illustrated in Figure 4. Make sure the tool is

connected to an outlet having the same

configuration as the plug. No adapter is available

or should be used with this tool. If the tool must be

reconnected for use on a different type of electric

circuit, the reconnection should be made by

qualified service personnel; and after reconnection,

the tool should comply with all local codes and

ordinances.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the Band Saw.

Figure 4

7.7 Extension Cords

The use of extension cords is discouraged; try to

position machines within reach of power source. If

an extension cord becomes necessary, make sure

the cord rating is suitable for the amperage listed

on the machine’s motor plate. An undersized cord

will cause a drop in line voltage resulting in loss of

power and overheating.

Use Table 1 as a general guide in choosing the

correct size cord. The smaller the gauge number,

the heavier the cord. If in doubt, use the next

heavier gauge.

Recommended Gauges (AWG) of Extension Cords

Ampere rating

Volts Total length of cord

in feet

120 25 50 100 150

240 50 100 200 300

More

than

Not more

than

Minimum gauge cord

0 6

18 16 16 14

6 10

18 16 14 12

10 12

16 16 14 12

12 16

14 12 NR NR

NR: Not Recommended.

Table 1

8.0 Adjustments

Tools required for adjustments:

Machinist square

Cross point (Phillips) screwdriver

Hex keys, 4mm/5mm/6mm

13mm wrench

Straight edge and gauge

8.1 Fence assembly

Refer to Figure 5.

Place fence body onto guide tube (as shown in

Figure 9). Raise fence lever all the way up to install

or remove fence from guide rail. Midway lever

position allows fence to slide along guide rail.

Lowest lever position locks fence in place.

Figure 5

8.2 Fence plate

Refer to Figures 6 and 7.

Loosen lock bar (A) using knobs (B). Pull out on

lock bar until it protrudes enough on which to slide

the aluminum fence plate from one end, as shown

in Figure 6. Retighten knobs.