13

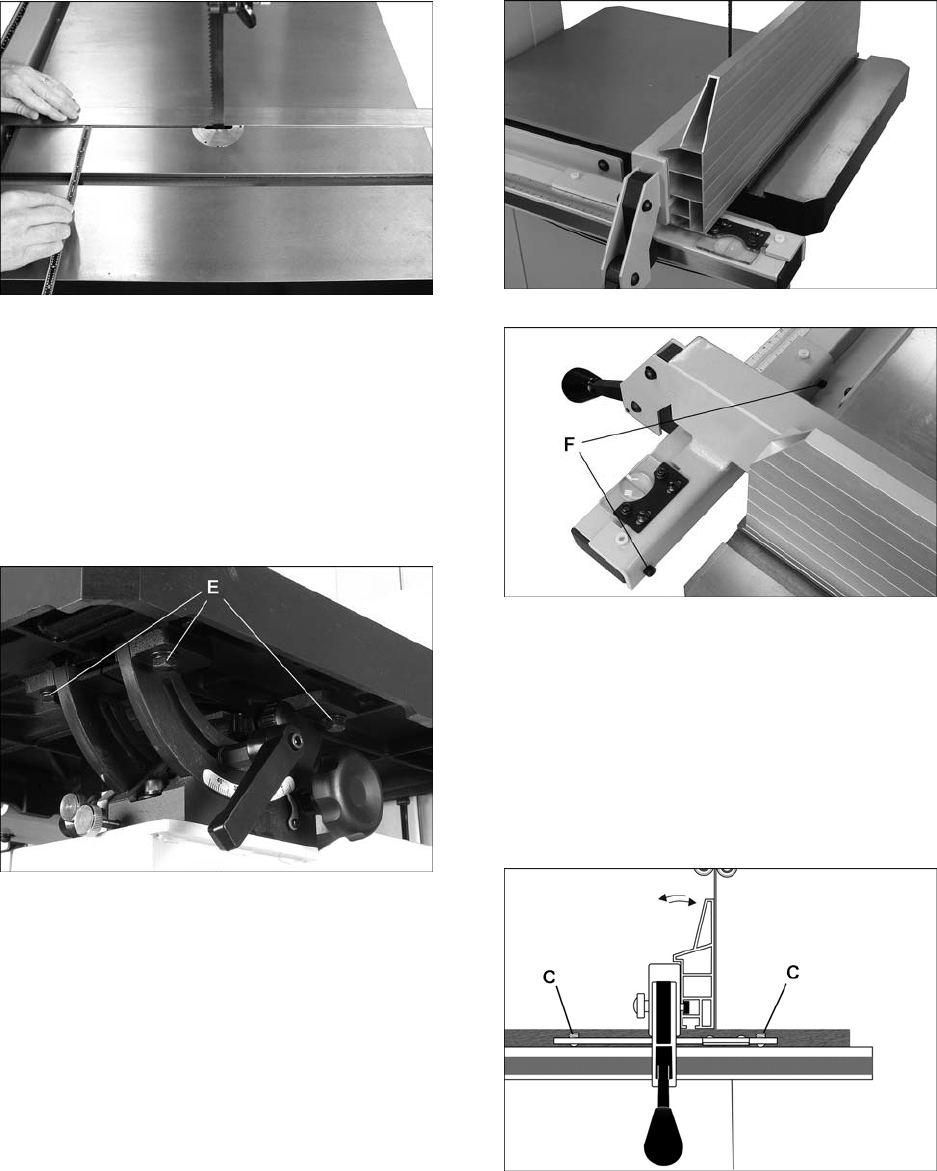

Figure 10

5. Use a gauge to carefully measure distance

from miter slot to straight edge. Take

measurements at both front and back of table

– these should be identical.

6. If miter slot is not parallel to blade, loosen four

screws (E, Figure 11) that secure table to

trunnion, and shift table as needed until miter

slot is parallel to blade.

7. Tighten the four screws.

Figure 11

8.6 Setting Fence Parallel to Blade

Refer to Figures 12 through 14.

Fence must be parallel to flat of blade for accurate

cutting. Since miter slot has been set parallel to

blade from the manufacturer (and confirmed by

user, as described in section 8.5), the miter slot

can be used to set fence parallelism.

1. Slide fence to edge of miter slot, as shown in

Figure 12. The fence should align with miter

slot along its entire length.

2. If adjustment is needed, use one of the back

adjustment screws (F, Figure 13) to turn fence

in line with miter slot (5mm hex key).

Figure 12

Figure 13

The fence must also be vertically parallel to blade.

Refer to Figure 14:

3. Make sure table has been set 90° to blade

(see section 8.9).

4. Slide fence (with aluminum plate securely

fastened) against blade; do not push into

blade. Turn either of the nylon adjustment

screws (C) until fence is parallel to blade along

vertical length of fence.

Figure 14

8.7 Fence Locking Tightness

The tightness of fence against guide rail tube can

be adjusted by rotating back adjustment screws (F,

Figure 13). Rotate the two screws equally

(clockwise to tighten).

Because these screws are also used to align fence

to blade, after adjusting fence locking tightness,