16

8.12 Blade Tracking

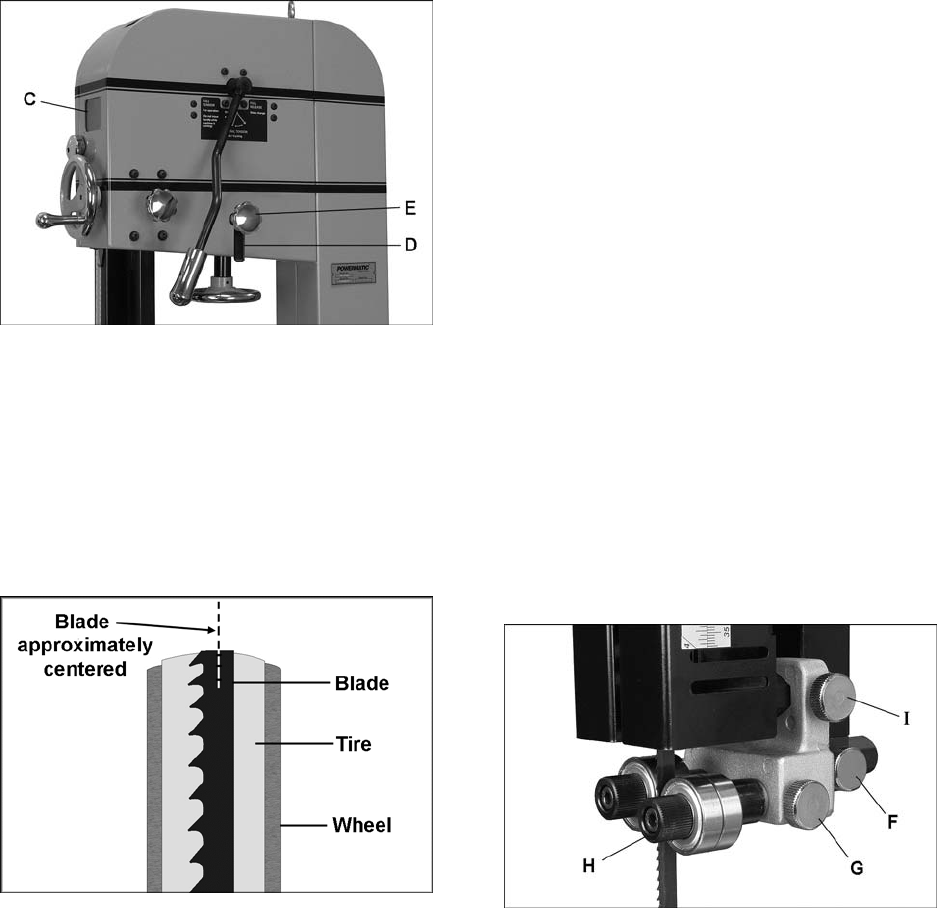

Refer to Figures 21 and 22.

After proper tensioning, the blade must be tracked.

“Tracking” refers to position of blade on the wheels

while machine is in operation. Tracking should be

checked periodically, and is mandatory after every

blade change. Blade tracking is done by hand with

machine disconnected from power.

1. Disconnect machine from power source.

2. Blade must be correctly tensioned (section

8.11).

3. Make sure blade guides and other parts of

machine will not interfere with blade

movement. Lower guide post until you can see

blade through tracking window (C).

Figure 21

4. Set quick tension lever initially to “Partial

Tension-Idle/Tracking” position, as shown in

Figure 21.

5. Open upper door to expose wheel.

6. Rotate wheel by hand, observing position of

blade through tracking window. As you rotate

wheel, move lever to “Full Tension” position.

The blade should continue to ride upon center

of tire (Figure 22).

Figure 22

7. If blade tends to move toward edge of wheel,

set lever to “Partial Tension-Idle/Tracking.”

8. Loosen lock handle (D, Figure 21) and slightly

rotate tracking knob (E) with your right hand

while continuing to rotate wheel with your left.

Observe blade through tracking window.

Rotating knob clockwise will cause blade to

move toward rear edge of wheel. Rotating

knob counterclockwise will cause blade to

move toward front edge of wheel.

IMPORTANT: This adjustment is sensitive;

perform in small increments and give blade

time to react to changes.

9. When blade is tracking in center of wheel, re-

tighten lock handle (D), and close upper door.

10. Move tension lever to “Full Tension” position,

and connect band saw to power. Turn it on for

a brief time to observe the blade in action

through tracking window.

11. If further adjustments are needed, disconnect

from power and repeat above procedure.

NOTE: An interlock switch in the upper housing

prevents operation of saw unless tension lever is in

full tension position.

8.13 Upper Blade Guides

The bearing guides should be set so that contact

between blade and guides will occur only when

blade is under pressure from a workpiece. To

adjust upper bearing guides for proper blade

control, proceed as follows.

Refer to Figures 23 through 24.

1. Disconnect machine from power source.

2. Blade must already be tensioned and tracking

correctly. Place quick tension lever in “Full

Tension” position.

3. Lower guide post until upper guide bearings

are a few inches off the table. (The reason for

this will be evident later in section 8.17)

4. Loosen lock knob (F, Figure 23).

Figure 23

5. Slide entire guide bracket until front of guide

bearings are about 0.015” (1/64”) behind the