24

Figure 44

3. Grease blade tension screw (Figure 45).

Figure 45

4. Oil any pins, shafts, and joints. (Do not get oil

on pulleys or belts.)

Note: Bearings on the band saw are pre-lubricated

and sealed, and do not require attention.

12.0 Blade Selection

Using the proper blade for the job will increase the

operating efficiency of your band saw, help reduce

necessary saw maintenance, and improve your

productivity. Thus, it is important to follow certain

guidelines when selecting a saw blade.

Here are factors to consider during selection:

• Type of material you will be cutting.

• Thickness of workpiece.

• Features of workpiece, such as bends or

curves with small radii.

These factors are important because they involve

basic concepts of saw blade design. There are five

(5) blade features that are normally changed to

meet certain kinds of sawing requirements. They

are:

1. width

2. pitch (number of teeth per inch)

3. tooth form (or shape)

4. “set” of the teeth

5. the blade material itself

Width

Band saw blades come in different standard

widths, measured from back edge of blade to tip of

tooth. Generally, wider blades are used for ripping

or making straight cuts, such as resawing.

Narrower blades are often used when the part

being cut has curves with small radii. When cutting

straight lines with a narrow blade, the blade may

have a tendency to drift (see section 10.5).

Pitch

Pitch is measured in “teeth per inch” (TPI) and can

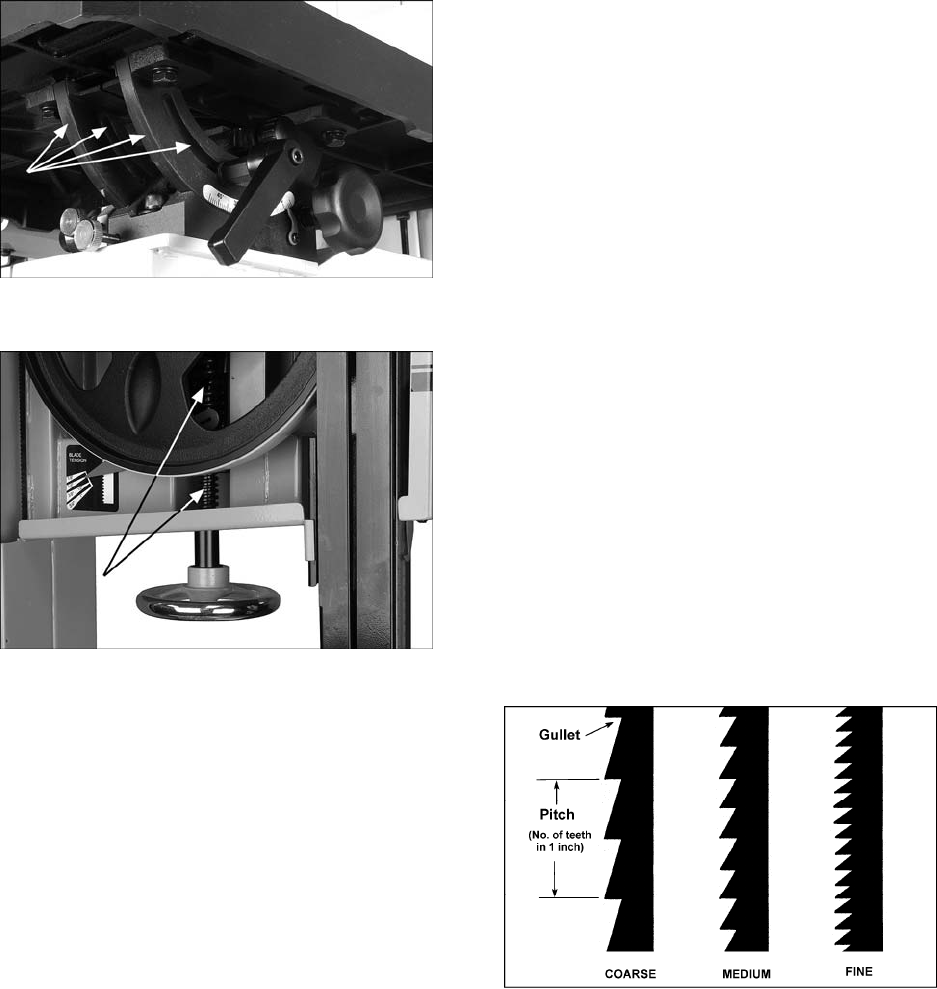

be constant or variable. Figure 46 shows blades

with different pitches.

A fine pitch (more teeth per inch) will cut slowly but

more smoothly. A coarse pitch (fewer teeth per

inch) will cut faster but more roughly.

As a rule of thumb, the thicker the workpiece, the

coarser will be the blade pitch. If you have to cut a

hard or very brittle material, you will probably want

to use a blade with a finer pitch in order to get

clean cuts.

Using a blade with too few teeth may cause

vibration and a rough cut, while too many teeth

may cause the gullets to fill with sawdust and

overheat the blade.

As a general rule, use a blade that will have from 6

to 12 teeth in the workpiece at any given time.

Figure 46 – Blade Pitch

Shape

Figure 47 shows common types of tooth shape, or

form. Tooth shape has an effect on cutting rate.

The Regular, or standard blade, has evenly spaced

teeth that are the same size as the gullets, and a

zero-degree rake (i.e. cutting angle). These offer

precise, clean cuts at slower rates. It is usually a

good choice for cutting curves and making

crosscuts.

The Skip type has fewer teeth and larger gullets

with a zero rake. It allows faster cutting rates than

the Regular type, with a slightly coarser finish. It is

useful for resawing and ripping thick stock, as well

as cutting softwoods.