21

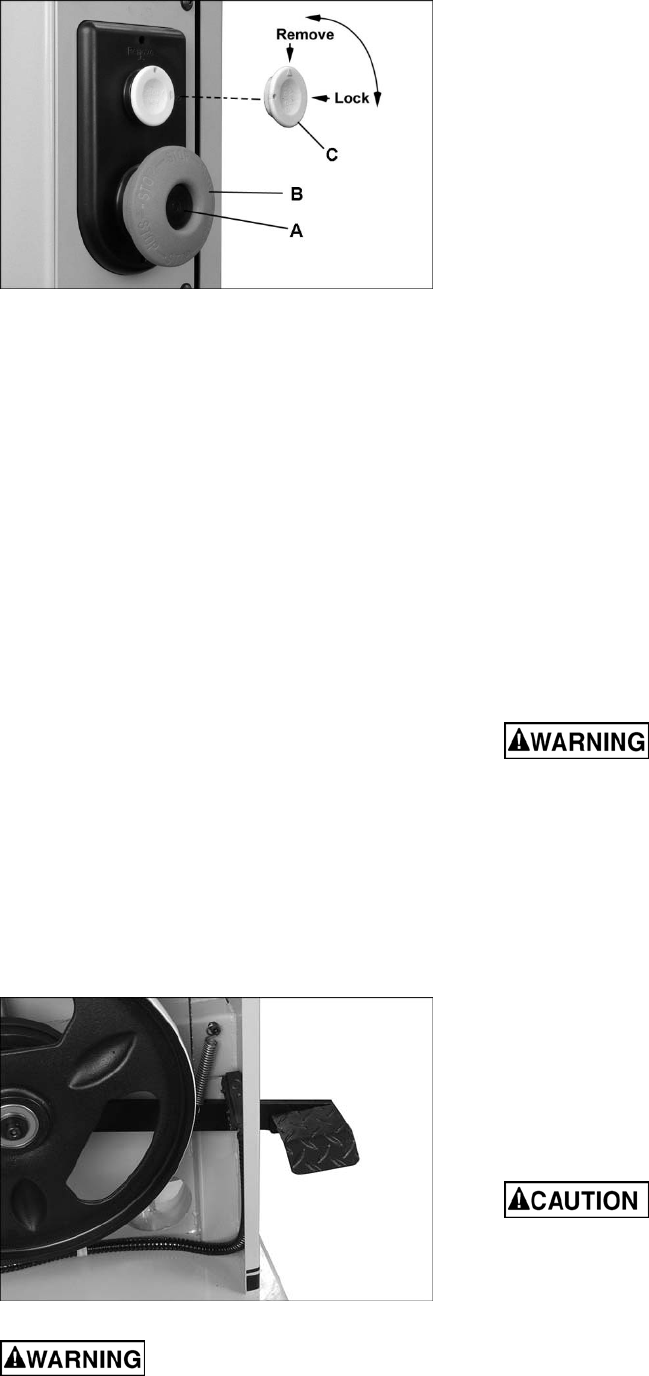

Figure 36

9.2 Safety Key

The start/stop switch on the Band Saw comes

equipped with a magnetic safety key (C, Figure

36). When in place on the switch, the magnetic

safety key trips a relay which will allow the machine

to start and stop when the respective switches are

pressed. Being magnetic, the lock can be removed

to make the machine inoperable and can be

hidden for safe storage by attaching it to another

magnetic surface.

When using the band saw, place the key on the

switch cover, lining up arrow on key with REMOVE

arrow on cover. Then rotate key so that arrow lines

up with LOCK arrow on cover. This will prevent the

safety key coming loose from vibration when

machine is in use.

9.3 Brake Pedal

When the stop button is used to shut off the band

saw, the blade will coast slowly to a stop. An

alternate method of stopping the machine is to

press and hold the brake pedal, shown in Figure

37. The blade will stop moving in approximately

three to four seconds after pedal is pressed.

Restart saw by pressing start switch on column.

NOTE: Unnecessary and excessive use of brake

pedal may shorten life of brake pad.

Figure 37

After machine is shut off, allow

wheels and blade to come to a complete stop

before opening guards/doors, making adjustments,

or leaving the area.

10.0 Operation

The following section contains basic information,

and is not intended to cover all possible

applications or techniques using the band saw.

Consult published sources of information, acquire

formal training, and/or talk to experienced band

saw users to gain proficiency and knowledge of

band saw operations.

(The following figures may or may not show your

specific model, but procedures are the same.)

10.1 General Procedure

1. Make sure blade is adjusted correctly for

tension and tracking, and that upper and lower

guide bearings and thrust bearings are set in

proper relation to blade.

2. Adjust guide post so that guide bearings are

just above workpiece (about 1/8”) allowing

minimum exposure to blade.

3. If using the fence, move it into position and

lock it to guide rail. If using miter gauge for a

crosscut, the fence should be moved safely

out of the way.

4. Turn on band saw and allow a few seconds for

machine to reach full speed.

Whenever possible, use a push

stick, hold-down, power feeder, jig, or similar

device while feeding stock, to prevent your hands

getting too close to the blade.

5. Place the straightest edge of the workpiece

against the fence for a rip cut; or against the

miter gauge for a crosscut. Push workpiece

slowly into blade, while also keeping it pressed

against fence or held against miter gauge. Do

not force workpiece into blade.

Additional operating tips:

Make relief cuts whenever possible. A relief cut is

an extra cut made through the waste portion of a

workpiece up to the layout line. When that

intersection is reached by the blade while following

the layout line, the waste portion comes free. This

helps prevent pinching of the back edge of the

blade in the cut.

When cutting, do not overfeed

blade; overfeeding will reduce blade life, and may

cause blade to break.

When cutting long stock, the operator should use

roller stands, support tables, or an assistant to help

stabilize the workpiece.