7

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong ground-

ing plugs and 3-pole receptacles that accept the tool's plug.

When using a power tool at a considerable distance from the

power source, use an extension cord heavy enough to carry

the current that the tool will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the chart

provided below to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed by

Underwriter's Laboratories (UL) should be used.

Length of Extension Cord Wire Size (A.W.G.)

Up to 25 feet 14

26-50 feet 14

When working with the tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the let-

ters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or ex-

posed wires and cut or worn insulation.

CAUTION:

Keep the cord away from the cutting area and

position the cord so that it will not be caught on

material, tools, or other objects during cutting.

ELECTRICAL CONNECTION

Your drill press is powered by a precision built electric mo-

tor. It should be connected to a power supply that is 120

volts, 60 Hz, AC only (normal household current). Do not

operate this tool on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat.

If the machine does not operate when plugged into an outlet,

double check the power supply.

POWER SUPPLY

Before operating your drill press, check your power sup-

ply and make sure it meets the requirements listed on the

tool’s data plate. A substantial voltage drop will cause a

loss of power and machine overheating.

Common causes of power loss and machine overheat-

ing are insufficient extension cord size and multiple tools

operating from the same power source.

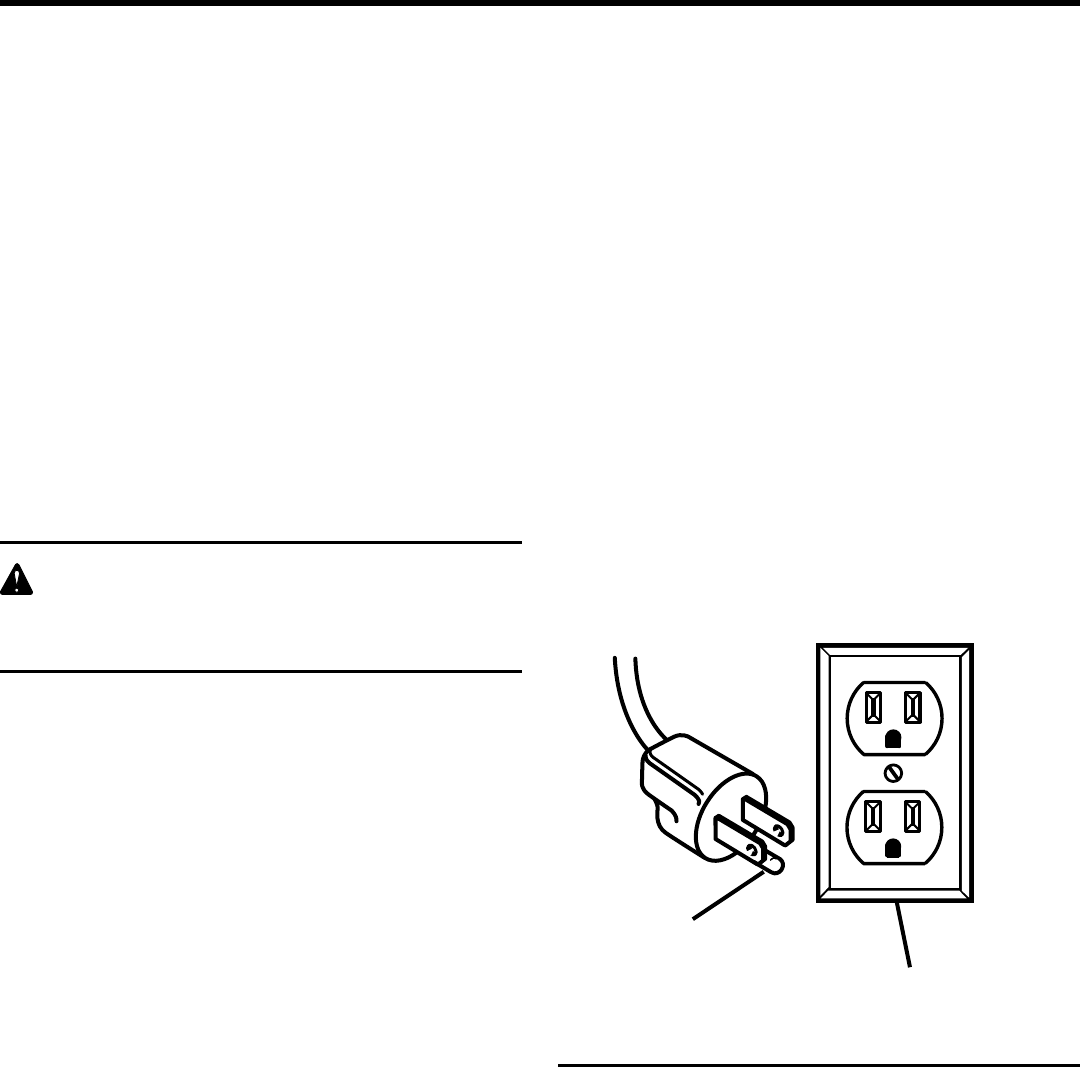

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding pro-

vides a path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with an elec-

tric cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have

the proper outlet installed by a qualified electrician. Improper

connection of the equipment-grounding conductor can result

in a risk of electric shock. The conductor with insulation having

an outer surface that is green with or without yellow stripes is

the equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet

like the one shown in Figure 1. It also has a grounding pin

like the one shown.

GROUNDING

PIN

COVER OF GROUNDED

OUTLET BOX

Fig. 1