18

19

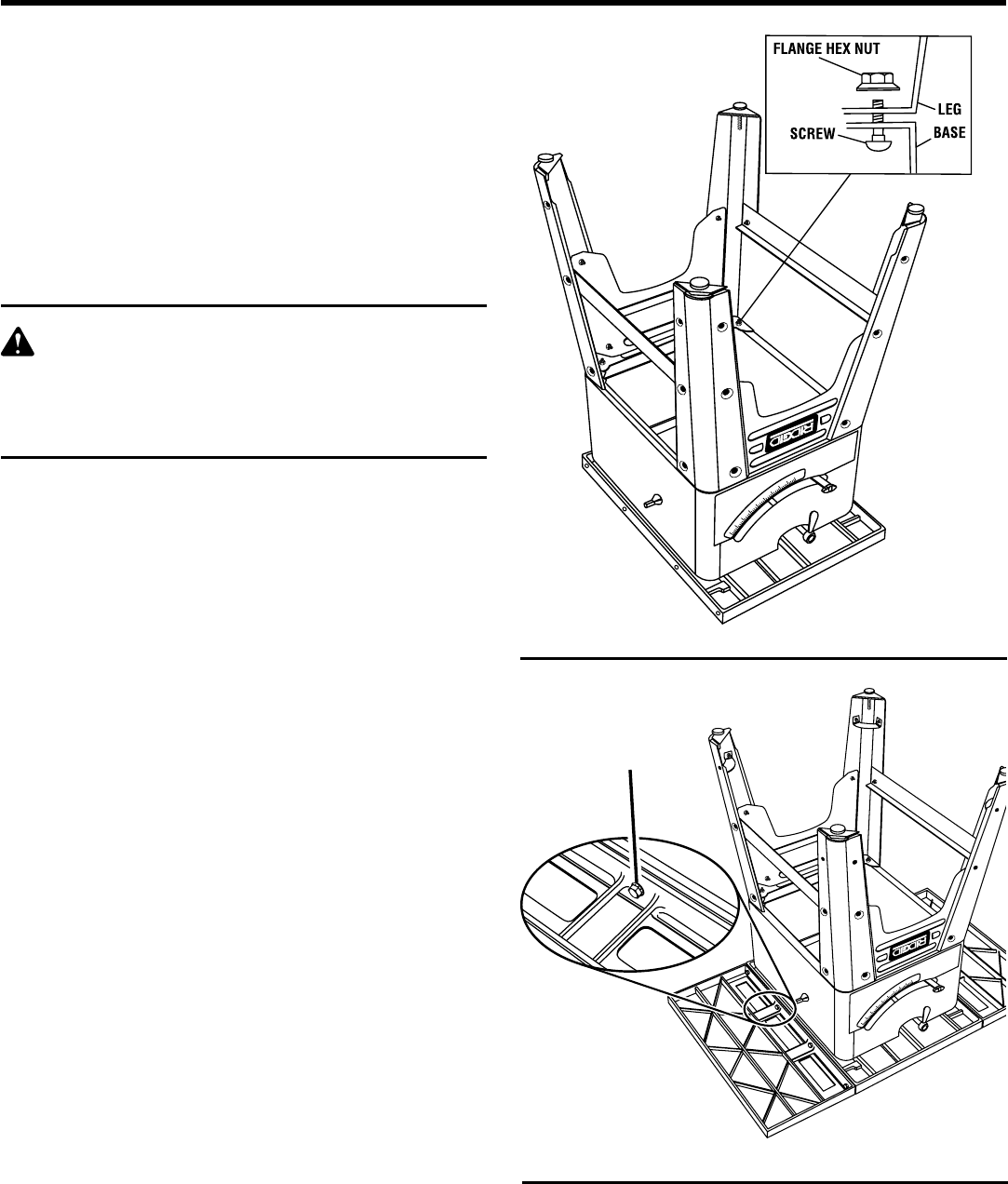

ASSEMBLY

n Thread one hex nut on the screw on the leveling foot and

turn until it stops.

n Slip a foot brace onto the leveling foot before placing the

leveling foot in the hole in the bottom of the leg. Secure

with another hex nut.

n Adjust the feet all the way to the bottom of the leg. Using

a wrench, securely tighten all hex nuts.

This completes the leg stand.

TO MOUNT THE TABLE SAW TO THE LEG

STAND

See Figure 12.

WARNING:

Do not lift the saw without help. Hold it close to

your body. Keep your knees bent and lift with

your legs, not your back. Ignoring these precau-

tions can result in back injury.

n Locate the following hardware:

8 screws (5/16-18 x 5/8 in.)

8 hex nuts (5/16-18)

n Place the saw table upside down on a smooth surface,

such as cardboard, on the floor.

n Place the leg stand on the table saw base. Align the holes

in the table with the holes in the legs.

NOTE: The front panel is the one with the Ridgid logo

and must be on the front of the saw base.

n Insert a screw through the hole in the saw base and the

hole in the leg stand. Add a hex nut. Hand tighten.

n Repeat for remaining holes. Tighten all hardware with a

wrench. You may find it helpful to use one wrench to hold

the head of the bolt and one to tighten the hex nut.

TO INSTALL EXTENSION TABLES

See Figure 13.

n With the table saw still in the upside down position, place

a table extension against the table top.

n Insert four screws (5/16-18 x 3/4 in. with washer) through

the holes in the table extension and screw into the table

top. Do not tighten.

NOTE: The holes in the table top are threaded.

n Repeat above step on the other table extension.

n Stand saw upright on leg stand.

NOTE: Do not lift the saw without help. This saw is

heavy.

n Line up the front edge of the extension table with the

front edge of the table top. Using a combination square,

check the alignment of the table top edge to the extension

rail edge. Tighten the two corner nuts only with a 1/2 in.

wrench.

n Check the center of the table top and extension table.

If necessary, use a C-clamp to align the edges. Tighten

the center nuts with a 1/2 in. wrench.

n Repeat steps for the other extension table.

Fig. 13

®

Fig. 12

®

SCREW

WITH

WASHER