42

43

®

0

5

10

15

20

25

30

35

40

45

ADJUSTMENTS

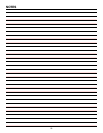

TO SET THE BEVEL INDICATOR AND BEVEL

STOPS AT 0˚ AND 45˚

See Figures 70 - 73.

To Check for Squareness, 90˚ Position:

n Unplug the saw and remove the switch key.

n Raise the blade to a 3 in. depth of cut.

n Push the bevel lock lever counterclockwise to loosen the

tilt clamp screw.

NOTE: Bevel lock lever is spring loaded and must be

pushed inward for disengaugement whenever it becomes

necessary to obtain a new grip on the screw head. Always

position the bevel lock lever downward to prevent binding

when tilting the saw blade.

n Turn the bevel adjusting handwheel counterclockwise.

Saw blade should now be square with the saw table and

the bevel indicator should point to 0˚.

n Place a combination square against the saw blade.

n If the saw blade is not square to the saw table, the 90˚

stop screw needs to be adjusted.

NOTE: From a position at the front of the saw, the 90˚

stop screw is on the left side of the throat plate.

n Using a 3/16 in. hex key, unscrew the 90˚ stop screw until

it is even with the top of the saw table.

n Turn the bevel adjusting handwheel until the saw blade

is square with the saw table.

n Screw the 90˚ stop screw until the saw blade starts

to move. Check again for squareness and readjust if

needed.

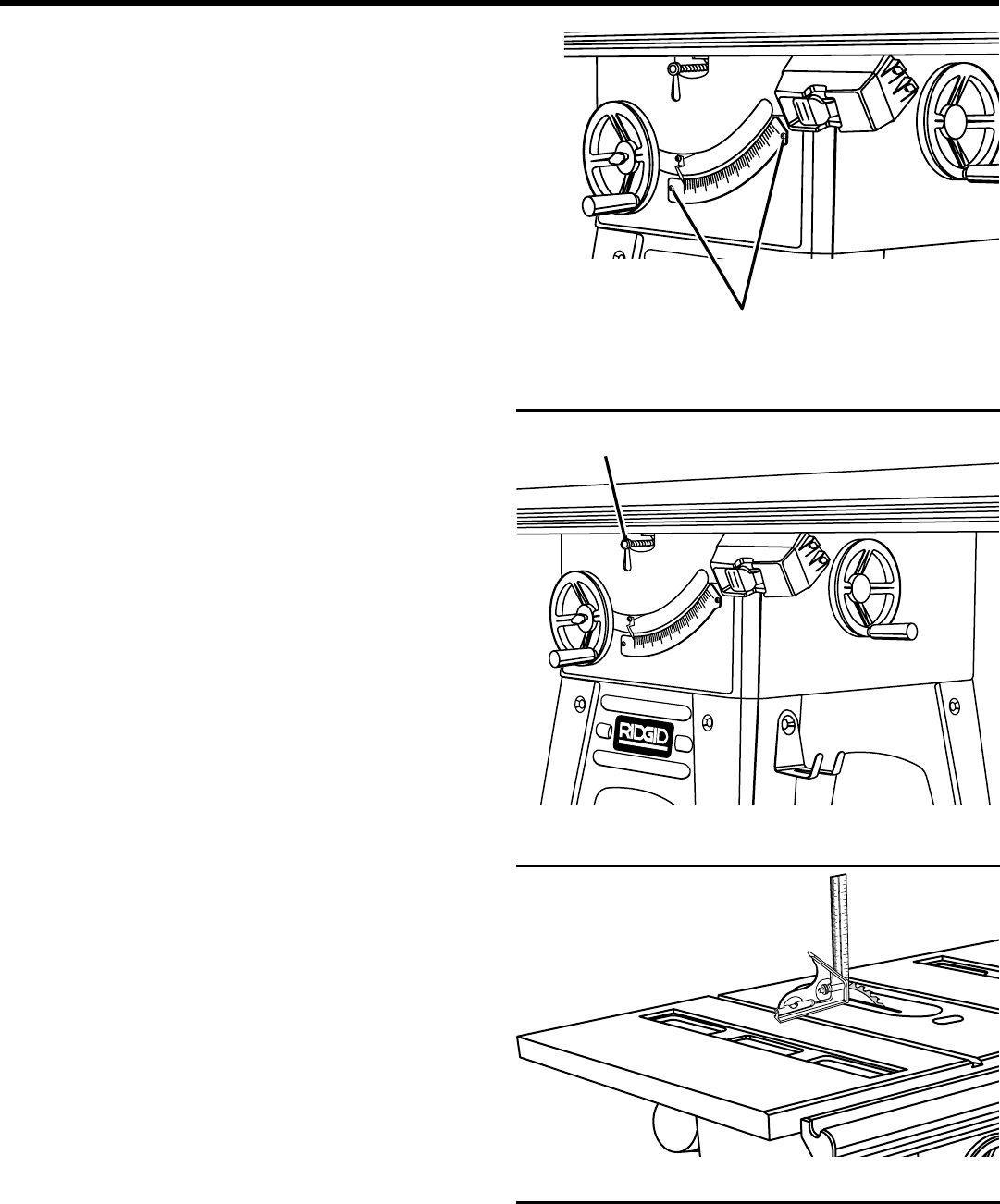

To Check for Squareness, 45˚ Position:

n Tilt the saw blade as far to the left as it will go.

n Place an accurate square against the saw blade checking

for the 45˚ angle.

n If the angle of the saw blade is not correct, the 45˚ stop

screw needs to be adjusted.

NOTE: From a position at the front of the saw, the 45˚

stop screw is on the left side of the throat plate.

n Using a 3/16 in. hex key, unscrew the 45˚ stop screw until

it is even with the top of the saw table.

n Turn the bevel adjusting handwheel until the saw blade

is square with the saw table.

n Screw the 45˚ stop screw until the saw blade starts

to move. Check again for squareness and readjust if

needed.

To Set the Bevel Indicator:

n With the saw blade at 90˚, the bevel indicator should be

pointing to 0˚.

n If not, remove the height adjusting handwheel.

n Loosen the screw and position the bevel indicator to point

to 0˚. Retighten screw.

Fig. 71

Fig. 72

Fig. 73

®

®

0

5

10

15

20

25

30

35

40

45

SCREWS

BLADE AT 90˚ POSITION

BEVEL LOCK LEVER