882.01749.00 12 of 93

6. EXTRUSION – “Simple”: Connect the input cable (2-conductor cable-gray) to a dry

contact (zero voltage) signal that indicates the extruder

screw is turning. (The connection in the controller should

be on terminal block #10 and PLC input X5.. A jumper wire

can also be installed on the same terminals (instead of a dry

contact.) if the feeder is to be started and stopped through the

feeder controller, and not with the extruder screw.

7. EXTRUSION – “Follower”: Connect the input cable (2-conductor cable-gray) to a

0-10 VDC, 0-20 mA, or 4-20 mA signal from the extruder

that indicates the screw speed (rpm) of the extruder. (The

connection inside the controller should be on terminals blocks

51and 54.

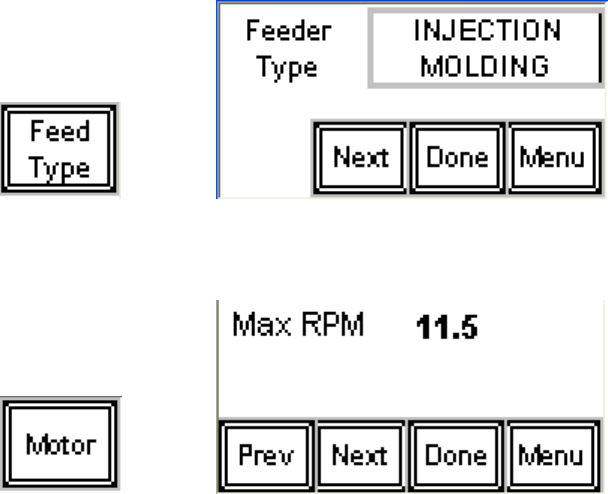

Feeder Configuration - Injection Molding:

Touch the ACS logo on the main menu screen to access the configuration menu. See section # for

details.

Feeder Type Selection. Select injection molding (default value).

Maximum Motor speed. Enter nominal motor speed.