882.01749.00 27 of 93

initially displayed is the weight which would result in a motor speed of 25%. The valid range of values would

then be ¼ to 2.5 times this initial value.

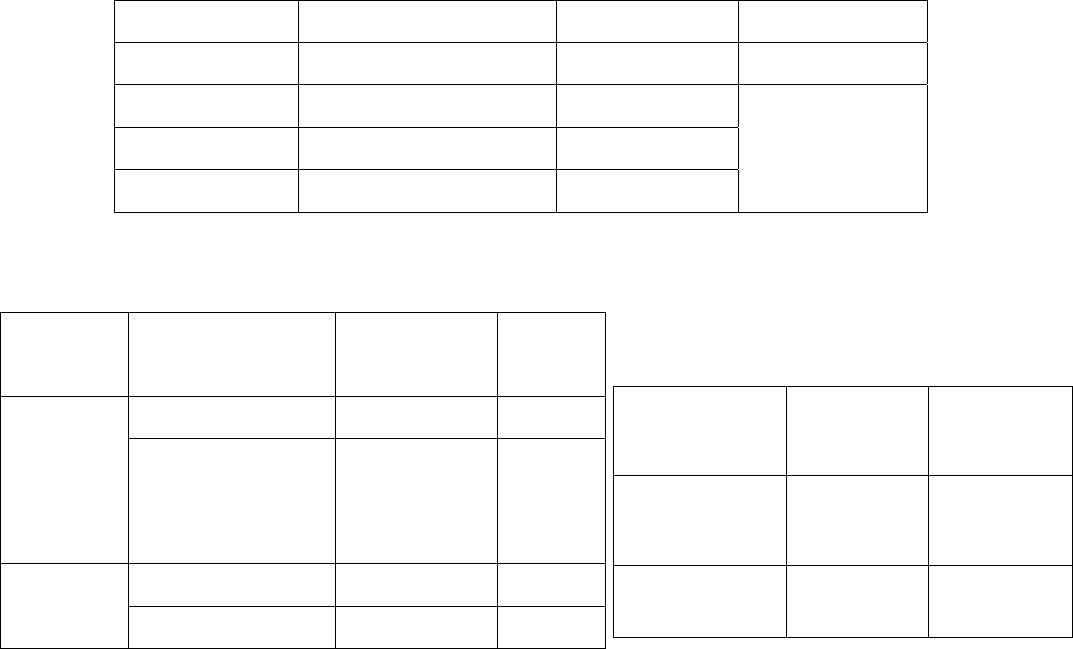

“DD” Pellet Discs

Disc Calibration Number No. of Pockets Disc Thickness

DD 30-030672 1.75 72 3 mm

DD 30-051040 5.00 40

5mm DD 30-051725 8.00 25

DD 30-051818 15.00 18

“DT” Pellet & Regrind Discs

“DP” Powder Discs

Additive Sample weighing.

Weighing samples of additive provides for more precise control of feed rate. Up to 5 samples can be

weighed. All weights entered are averaged to arrive at a value to be used during operation. The weighing

process may be skipped altogether, in which case the calibration weight is used for calculations of feed rate.

Weight Calibration.

The final step of recipe setup is weight calibration. This procedure is common to all types of presses

supported. After entering the calibration weight, pressing the “Next” button displays the following screen:

Disc

Thickness

Disc

Calibration

Number

No. of

Pockets

10 mm

DT 30-101820 32.00 20

DT 30-102025

(“Sure-shot” - 20

oval holes) 38.00

20 Oval

20mm

DT 30-203012 100.00 12

DT 30-204010 175.00 10

Disc

Calibration

Number

Disc

Thickness

DP 30-050940

17.00

5mm

DP 30-250940 8.00 2.5mm