882.01749.00 85 of 93

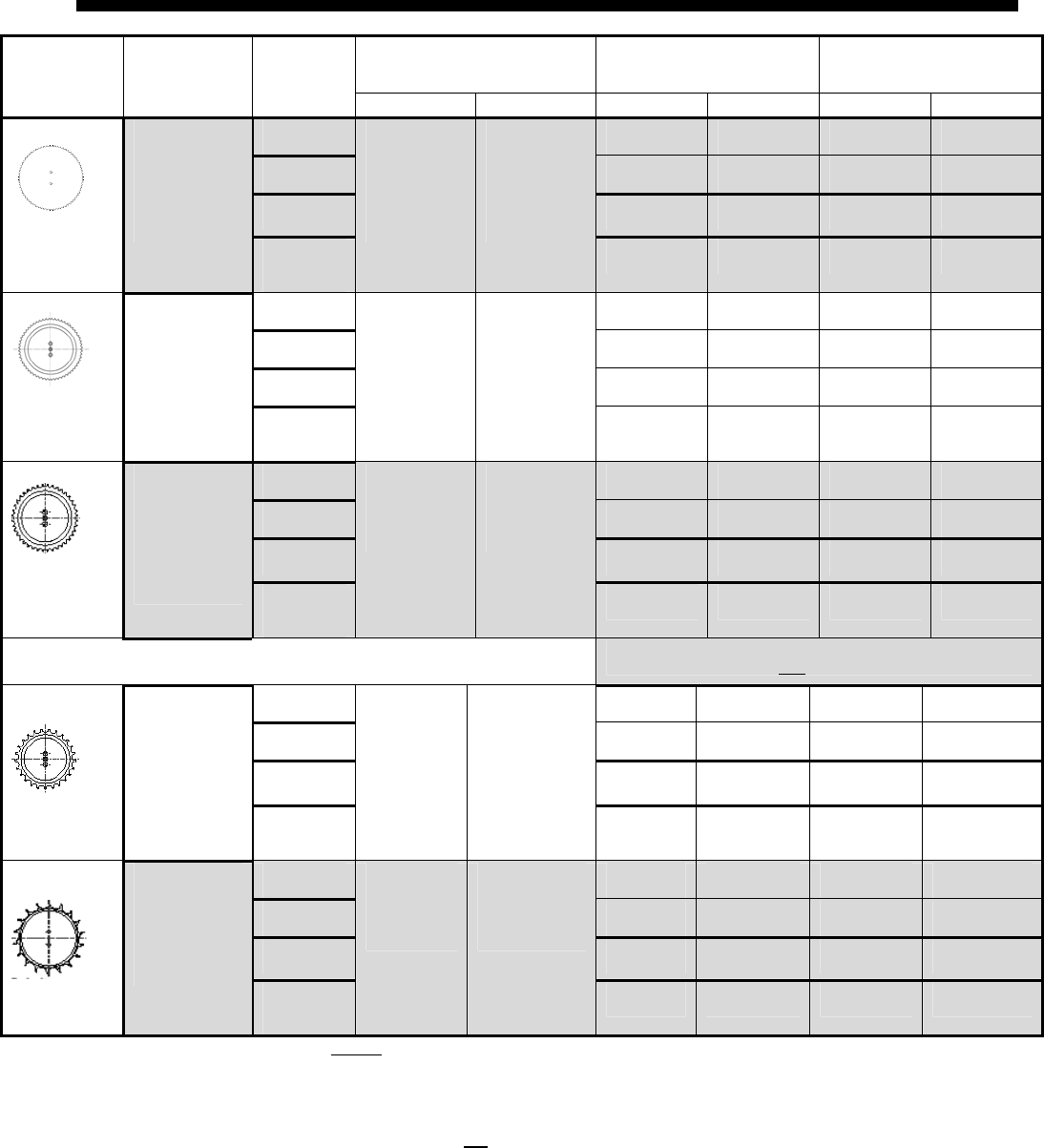

Appendix B Disc Sizing Guides

Disc

Disc

Nomenclature

Min/Max

Disc RPM

Amount of Material Dispensed

every Disc Revolution*

Minimum Throughput -

Continuous Running*

Maximum Throughput -

Continuous Running*

35 lbs./ft

3

44 lbs./ft

3

35 lbs./ft

3

44 lbs./ft

3

35 lbs./ft

3

44 lbs./ft

3

DD30-030672

Default

calibration #

1.50 g/rev

P030672

3 mm thick

5.7 mm diameter

72 pockets

CT100562

0.2 RPM

3 RPM

1.53 g/rev

0.02 g/hole

(micropellets)

1.95 g/rev

0.027 g/hole

(micropellets)

0.04 lbs/hr

0.02 kg/hr

0.04 lbs/hr

0.02 kg/hr

0.61 lbs/hr

0.28 kg/hr

0.77 lbs/hr

0.35 kg/hr

0.2 RPM

8.4 RPM

0.04 lb/hr

0.02 kg/hr

0.04 lb/hr

0.02 kg/hr

1.69 lbs/hr

0.77 kg/hr

2.17 lbs/hr

0.98 kg/hr

0.5 RPM

11.5 RPM

0.10 lb/hr

0.045 kg/hr

0.12 lb/hr

0.05 kg/hr

2.32 lbs/hr

1.05 kg/hr

2.89 lbs/hr

1.31 kg/hr

1.0 RPM

38 RPM

See Note 4

0.19 lb/hr

0.09 kg/hr

0.26 lb/hr

0.12 kg/hr

7.66 lbs/hr

3.47 kg/hr

9.63 lbs/hr

4.37 kg/hr

DD30-050660

Default

Calibration #

1.30 g/rev

P050660

5 mm thick

5.7 mm diameter

60 pockets

822.00738.00

0.2 RPM

3 RPM

1.35 g/rev

0.02 g/hole

1.70 g/rev

0.028 g/hole

0.04 lbs/hr

0.02 kg/hr

0.06 lbs/hr

0.03 kg/hr

0.42 lbs/hr

0.19 kg/hr

0.54 lbs/hr

0.24 kg/hr

0.2 RPM

8.4 RPM

0.05 lb/hr

0.02 kg/hr

0.07 lb/hr

0.03 kg/hr

1.1 lbs/hr

0.50 kg/hr

1.37 lbs/hr

0.62 kg/hr

0.5 RPM

11.5 RPM

0.09 lb/hr

0.04 kg/hr

0.10 lb/hr

0.05 kg/hr

1.46 lbs/hr

0.66 kg/hr

1.83 lbs/hr

0.83 kg/hr

1.0 RPM

38 RPM

See Note 4

0.17 lb/hr

0.08 kg/hr

0.22 lb/hr

0.10 kg/hr

6.48 lbs/hr

2.94 kg/hr

8.54 lbs/hr

3.87 kg/hr

DD30-051040

Default

calibration #

4.00 g/rev

051040

5 mm thick

10 mm dia.

40 pockets

CT21710

0.2 RPM

3 RPM

4.24 g/rev

0.11 g/hole

5.39 g/rev

0.13 g/hole

0.11 lb/hr

0.05 kg/hr

0.15 lb/hr

0.07 kg/hr

1.68 lbs/hr

0.76 kg/hr

2.14 lbs/hr

0.97 lbs/hr

0.2 RPM

8.4 RPM

0.11 lb/hr

0.05 kg/hr

0.15 lb/hr

0.07 kg/hr

4.71 lbs/hr

2.12 kg/hr

5.99 lbs/hr

2.72 kg/hr

0.5 RPM

11.5 RPM

0.27 lb/hr

0.12 kg/hr

0.35 lb/hr

0.15 kg/hr

6.33 lbs/hr

2.87 kg/hr

8.00 lbs/hr

3.62 kg/hr

1.0 RPM

38 RPM

See Note 4

0.55 lb/hr

0.25 kg/hr

0.70 lb/hr

0.32 kg/hr

21.19 lbs/hr

9.61 kg/hr

27.08 lbs/hr

12.28 kg/hr

Consult factory - 40 pocket disc and 35.5 rpm motor for small

pellets and coarse powder only

4-10 DD3

0-051725

Default

calibration #

7.30 g/rev

051725

5 mm thick

17 mm dia.

25 pockets

CT21711

0.2 RPM

3 RPM

7.37 g/rev

0.30 g/hole

9.38 g/rev

0.38 g/hole

0.20 lb/hr

0.09 kg/hr

0.24 lb/hr

0.11 kg/hr

2.92 lbs/hr

1.32 kg/hr

3.70 lbs/hr

1.68 kg/hr

0.2 RPM

8.4 RPM

0.20 lb/hr

0.09 kg/hr

0.24 lb/hr

0.11 kg/hr

8.18 lbs/hr

3.71 kg/hr

10.37 lbs/hr

4.70 kg/hr

0.5 RPM

11.5 RPM

0.48 lb/hr

0.22 kg/hr

0.61 lb/hr

0.27 kg/hr

11.0 lbs/hr

4.99 kg/hr

14.0 lbs/hr

6.36 kg/hr

1.0 RPM

38 RPM

See Note 4

1.00 lb/hr

0.44 kg/hr

1.25 lbs/hr

0.57 kg/hr

37.04 lbs/hr

16.80 kg/hr

47.10 lbs/hr

21.36 kg/hr

4-11 DD3

0-051818

Default

calibration #

13.50 g/rev

051818

5 mm thick

18 mm dia.

18 pockets

CT23057

0.2 RPM

3 RPM

13.42 g/rev

0.75 g/hole

17.08 g/rev

0.95 g/hole

0.35 lb/hr

0.16 kg/hr

0.44 lb/hr

0.20 kg/hr

5.34 lbs/hr

2.42 kg/hr

6.80 lbs/hr

3.08 kg/hr

0.2 RPM

8.4 RPM

0.35 lb/hr

0.16 kg/hr

0.44 lb/hr

0.20 kg/hr

14.96 lbs/hr

6.79 kg/hr

19.03 lbs/hr

8.63 kg/hr

0.5 RPM

11.5 RPM

0.85 lb/hr

0.39 kg/hr

1.12 lbs/hr

0.51 kg/hr

19.60 lbs/hr

8.89 kg/hr

25.63 lbs/hr

11.62 kg/hr

1.0 RPM

38 RPM

See Note 4

1.76 lbs/hr

0.80 kg/hr

2.20 lbs/hr

1.00 kg/hr

67.44 lbs/hr

30.59 kg/hr

85.90 lbs/hr

38.95 kg/hr

Note 1: This guide is to be used for general disc selection for Digital Dosing unit applications. All rates shown are based on

continuous throughput of free-flowing materials. Consult factory for regrind, powder and all hard-to-flow materials.

Note 2: Minimum recovery time is one (1) second, and maximum rate is 9.5 disc revolutions in one screw recovery cycle (injection

mode). Use correct disc for molding applications to ensure proper dispensing of material during the recovery cycle.

Note 3: Feeder should not run continuously below 15% of maximum speed – use lower RPM motor or disc with smaller pockets.

Note 4: 35.5. and 38 rpm motors can only be used with soft pellets – may not have enough torque to cut hard pellets, i.e. PC, PET,

nylon, etc., especially when the shear gets dull.