DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #3 (07/13/06) PAGE 18

ASSEMBLY INSTRUCTIONS/OPERATIONS

3) Using the funnel, fill the fuel tank with fresh,

clean fuel according to the specifications

outlined in the material supplied by the engine

manufacturer. Do not overfill the tank or spill any

fuel. If the fuel tank incorporates a screen mesh

to prevent debris from falling into the tank, do

not remove to increase the fill rate. Replace the

filler cap. Wipe away any excess spilled fuel.

DANGER

MANY FUELS ARE EXTREMELY FLAMMABLE.

DO NOT SMOKE NEAR THE FUEL TANK. DO

NOT FILL THE FUEL TANK WITH THE ENGINE

RUNNING OR IF IT IS HOT. ALLOW AMPLE TIME

BETWEEN EACH REFUELING FOR THE ENGINE

TO COOL.

Operation

THEORY OF OPERATION.

Application: All Models.

The DFG Series SURFACE GRINDERS operate on

the principle of various multi-accessory attachments

being utilized at rotational speeds to make direct

contact with a work surface. Various types of multi-

accessory attachments are secured to recesses

provided in two, counter-rotating, aluminum discs

located on the bottom of the machine. The specific

type of multi-accessory attachment utilized during

the grinding process directly affects the type of

material removed, the material removal rate and the

resulting flatness and smoothness of the surface.

The grinding process is directly controlled by these

conditions:

1) The use of a suitable mechanism (multi-

accessory attachment) of proper design and

configuration to grind the work surface and

remove material while delivering acceptable

service life.

2) Sufficient static weight supporting the multi-

accessory attachment to allow it to effectively

penetrate the work surface and remove material.

3) Adequate horsepower capable of propelling the

multi-accessory attachment against the work

surface to deliver acceptable productivity rates.

Since no two materials are exactly alike, no two work

surface materials can be penetrated and removed by

the exact same method. The nature of the grinding

process, along with operator experience, skill and

common sense, would suggest that efficient and

productive material removal is a matter of trial and

error. Combinations of multi-accessory attachment

type, condition, and feed rate are direct factors that

will also determine the overall success of the job

application.

MULTI-ACCESSORY ATTACHMENTS AND

APPLICATIONS.

Application: All Models

While individual multi-accessory attachment design

and configuration may vary, basic operational

characteristics are identical: impact upon a work

surface material and remove a percentage of the

material. This common operational characteristic has

led to the development of the following popular multi-

accessory attachments:

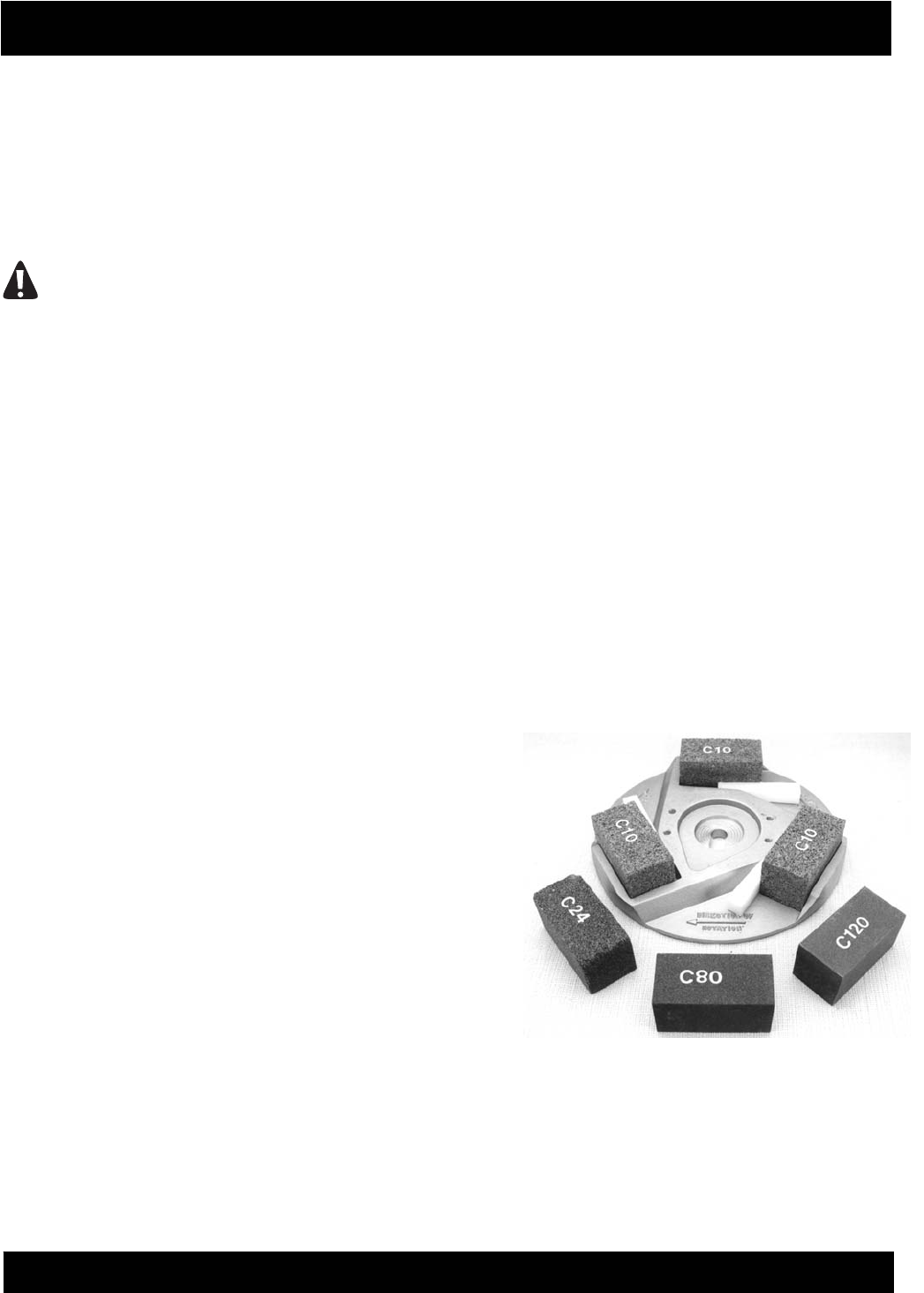

Grinding Stones

Grinding stones are available in a number of grades,

including: C06 extra coarse, C10 coarse, C24

medium, C80 fine and C120 super fine grade.

FIGURE 4. All stones incorporate silicon carbide as

the abrasive medium and employ a clay binder as

the matrix material. Vitrified type stones utilize an

oven baking process that produces greater service

life over other manufacturing processes. As the clay

material wears away, it exposes new, sharp, edges

of the imbedded silicon carbide material. All stones

have the identical 2" x 2" X 4" dimensions and are

secured to the machine by the use of a plastic

wedge.

FIGURE 4

The designation system for the grinding stones

utilizes a system similarly utilized for most abrasive

products: the larger the number, the finer the grain

structure and usually, the smoother resulting finish.