DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #3 (07/13/06) PAGE 21

ASSEMBLY INSTRUCTIONS/OPERATIONS

COST 1

PRODUCTIVITY 5

SERVICE LIFE 2

The beam flail should be replaced when the outside

diameter is worn to approximately 1-5/16 inch or the

inside diameter elongates to approximately 3/4 inch.

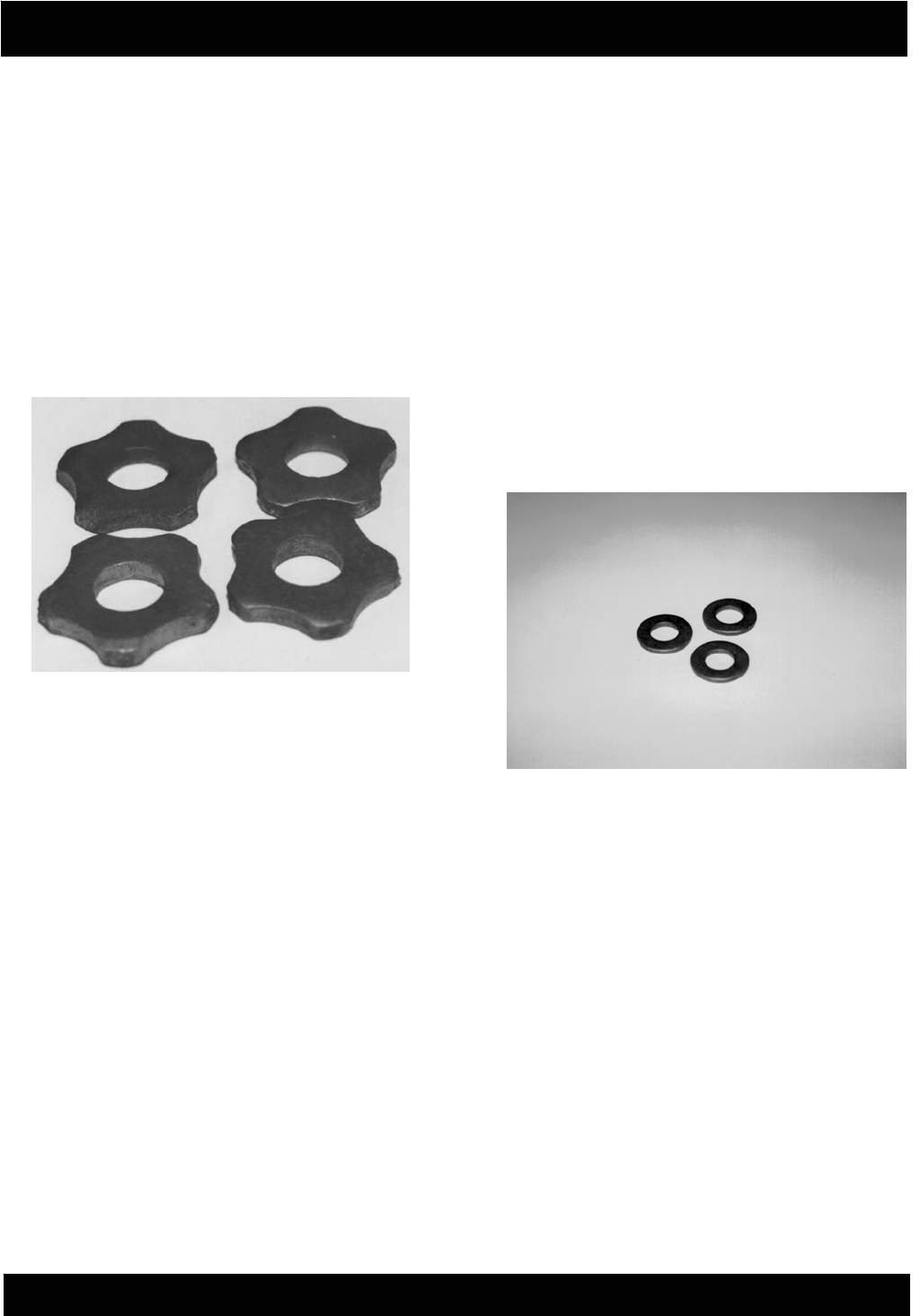

Pentagonal Flail

The pentagonal type flail is manufactured from high

carbon steel that is through hardened for additional

service life. Each section of the five sided design

features a small, tungsten carbide insert that is held

in position with copper brazing. It is highly effective

for scabbling or scarifying and delivers medium to

coarse finish texture. FIGURE 9.

FIGURE 9

Suggested Applications:

1) Heavy duty asphalt and concrete scarifying.

2) Heavy duty descaling of steel decks.

The pentagonal flail is designed for more aggressive

and rapid removal of a surface in comparison to the

beam flail. The addition of the tungsten carbide

inserts contributes to its long service life and higher

production rates. The use of tungsten carbide is also

the main reason for the cost differential between it

and the other flails. The design configuration yields a

rather coarse surface finish and texture. For many

job applications, this finish and texture will be

satisfactory. Some applications may require an

additional smoothing process. If the resulting surface

finish is too coarse to meet specifications, it can be

smoothed with the use of the star or beam flail.

COST 10

PRODUCTIVITY 8

SERVICE LIFE 10

The pentagonal flail should be replaced when two

successive tungsten carbide inserts break off or the

inside diameter elongates to approximately 3/4 inch.

In service, the flail body will wear much faster than

the tungsten carbide inserts. The copper brazing

used to weld the inserts into the body can fail and an

insert break off. The flail can still be used in service.

It will just wear a little faster and more uneven in that

particular area. As a general rule, a pentagonal flail

can be utilized until body wear will no longer support

the tungsten carbide inserts.

Spacer Washer

Spacer washers are stamped from high carbon steel

and heat-treated for additional service life. FIGURE

10.

FIGURE 10

Spacer washers serve the following functions:

1) Reduces the number of flails required to be

mounted on the scarifier block, thus reducing

purchase and operational costs.

2) Arrange the flails in a sequence or pattern that

minimize "blind" or "open" spots. Normally, at

least one spacer washer is inserted between two

consecutive flails. A scarifier block set up with

only star, beam or pentagonal flails will not

penetrate the work surface at satisfactory rates.

This configuration will minimize the hammering

or impact action of the flails.

Variances in material thickness and manufacturing

processes can affect the final thickness of both flails

and spacer washers. Because of this occurrence,

trial and error is important for assembling flails and

spacer washer on the scarifier block. By mixing and

matching flails and spacer washers of specific