DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #3 (07/13/06) PAGE 34

ASSEMBLY INSTRUCTIONS/OPERATIONS

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

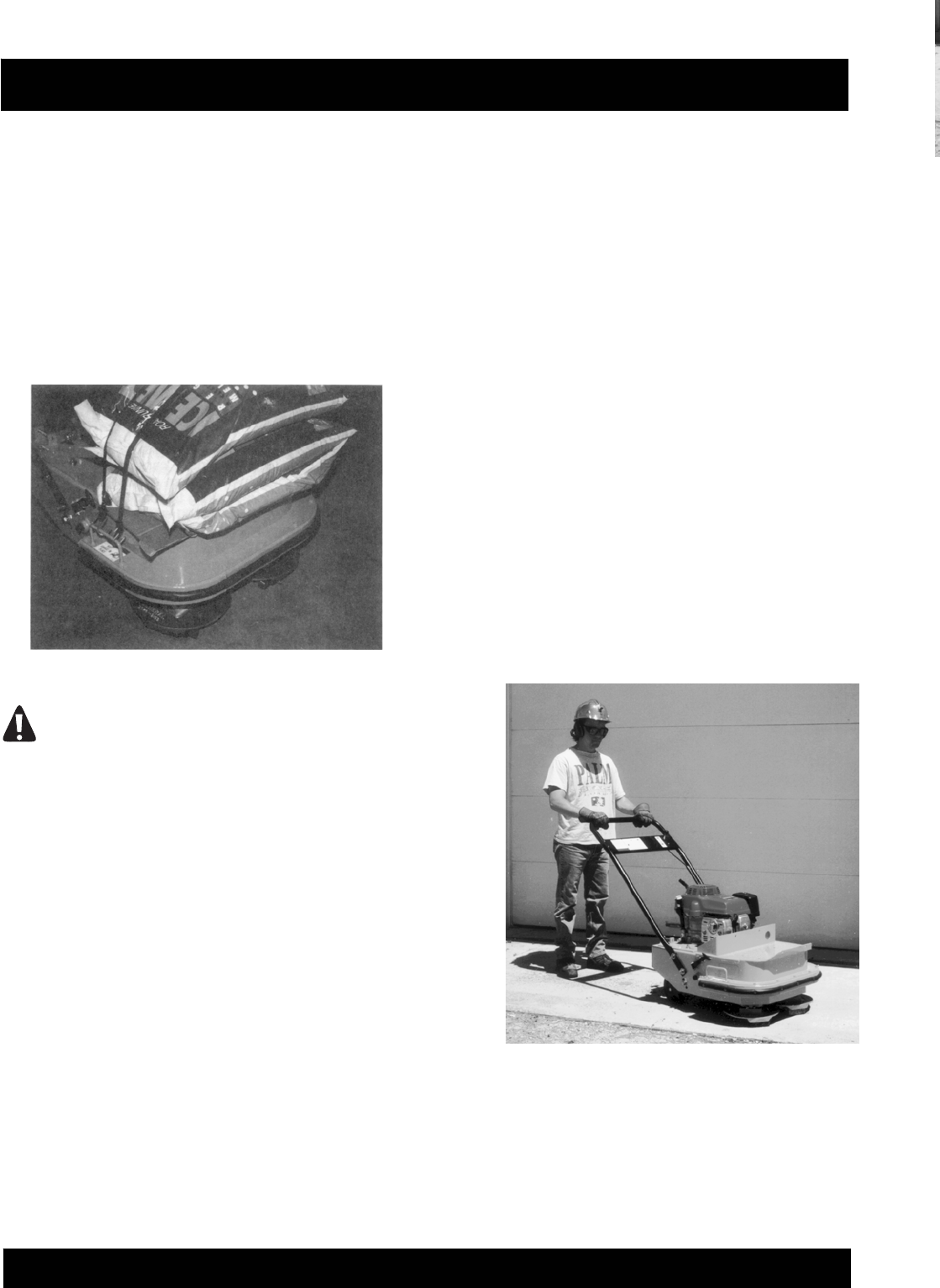

2) Productivity rates with the various multi-

accessory attachments can be increased with

the addition of external weight being applied to

the area over the counter-rotating discs.

FIGURE 36. Maximum allowable external weight

is 300 lbs. Exceeding this figure can result in

permanent structural damage to the SURFACE

GRINDER. Provisions for securing the weight by

the means of strapping or other, appropriate

methods is provided.

FIGURE 36

DANGER

DO NOT OPERATE THE SURFACE GRINDER

WITHOUT ALL EXTERNAL WEIGHT PROPERLY

SECURED TO THE MAIN FRAME. A SUDDEN

CHANGE IN MOVEMENT OR DIRECTION CAN

ALLOW THE UNSECURED WEIGHT TO FALL

OFF THE SURFACE GRINDER, RESULTING IN

LOSS OF MACHINE CONTROL, PROPERTY

DAMAGE AND/OR PERSONAL INJURY. THIS

PROCEDURE IS ESPECIALLY IMPORTANT

WHEN OPERATING THE SURFACE GRINDER ON

FLOORS AND/OR SURFACES ABOVE GROUND

LEVEL.

3) Proper operator posture and stance will enhance

operational safety and overall productivity.

FIGURE 38. For most job applications, operate

the engine at maximum, governed speed.

Consult the material supplied by the engine

manufacturer and the SPECIFICATIONS section

for specific information.

4) The wide variety of potential work surface

materials along with the corresponding variety of

job site environments, makes it impossible to

develop a standardized operating procedure for

the SURFACE GRINDER. Use of the SURFACE

GRINDER will require constant trial and error

testing until satisfactory results are achieved.

Experience gained over time and common

sense will help minimize the amount of

necessary testing. Many factors will directly

affect the operating parameters and/or

techniques utilized for a specialized job

application. Some of these factors include:

a) Work surface material yield and tensile

values. As a general rule, these values will

determine material removal rate per unit of

time. Materials with high yield and tensile

values will characteristically resist/limit

material penetration. For such materials, the

accepted procedure is to make a number of

multiple passes over the work surface rather

than attempt to make a single, deep pass.

The net effect is to actually increase

productivity: more material removed in less

time. Other added benefits to this technique

are decreased vibration, less operator

fatigue and increased component service

life.

FIURE 38

b. Higher material removal rates can

sometimes be achieved by making a series

of shallow passes 90 degrees to each other

to form a waffle like pattern. This technique

is especially useful when removing deeper

accumulations of rubber, paint, dirt debris,

etc. from industrial floors.